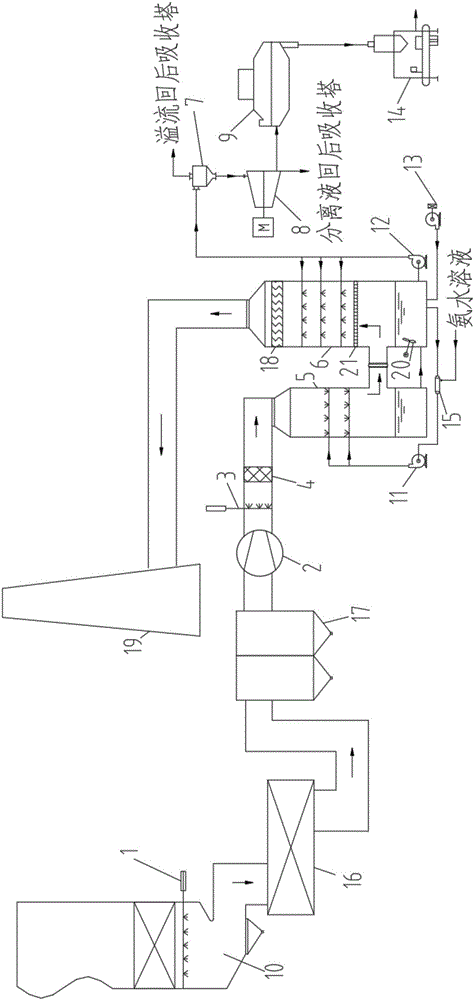

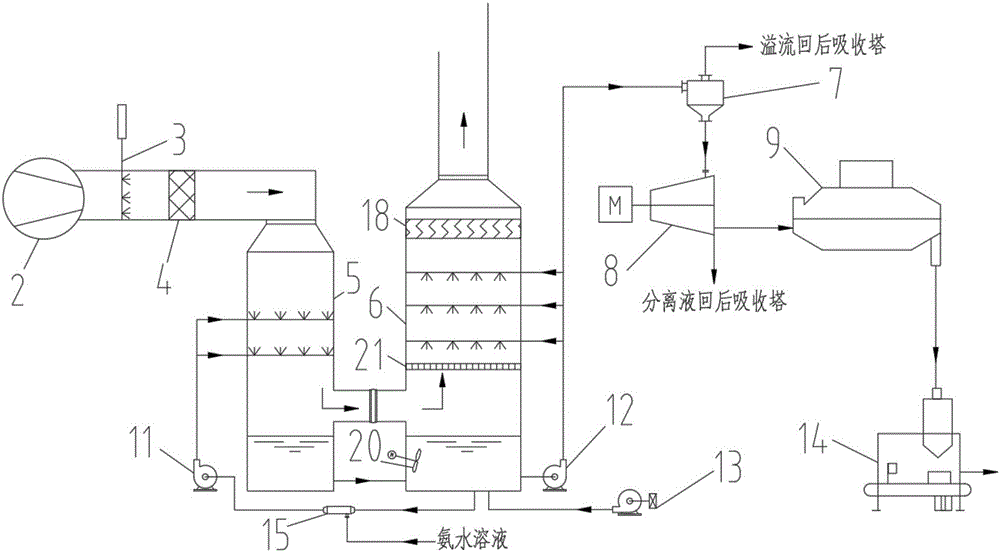

Desulfurization and denitration technology and system by ozone oxidation double-tower ammonia method

A double-tower ammonia method, desulfurization and denitrification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large investment in desulfurization and denitrification equipment, secondary soil pollution, complex combination control, etc., and achieve operating costs. The effect of low, secondary pollution and high technology integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

[0042] This ozone oxidation double-tower ammonia method desulfurization and denitrification process and its system first oxidize the nitrogen monoxide in the flue gas from the outlet 10 of the boiler economizer into nitrogen dioxide, and then in the double-tower desulfurization tower, make the flue gas The nitrogen dioxide and sulfur dioxide react with ammonia water to form ammonium nitrite, ammonium nitrate and ammonium sulfite, and then oxidize the ammonium nitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com