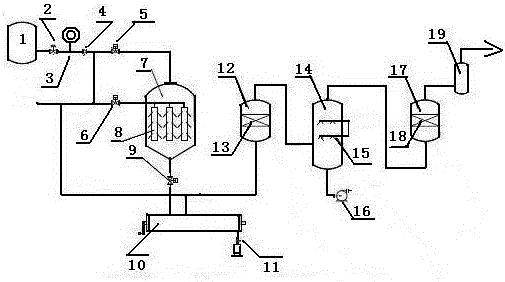

Closed-circuit internal circulation technology for gas collection in solid-liquid separation process

A solid-liquid separation and internal circulation technology, which is applied in filtration separation, separation methods, and dispersed particle separation, etc., can solve problems such as environmental pollution, increased post-processing difficulty, and inclusion of atomized droplets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The working method of the device comprises the following steps:

[0039]The mother liquor to be filtered containing solid particle impurities is separated from the solid and liquid through the cluster type backflushing filter 7 to remove the solid particles. The solid particles are filtered from the outside to the inside through the filter element, and a filter cake is formed on the surface of the filter element 8. When the filter cake reaches a certain When the thickness or filter reaches a certain filtration pressure difference, the filter cake needs to be removed online. Firstly open the exhaust / drying valve 5, the cluster type backflush filter 7 uses compressed gas to discharge the residual liquid and dry the filter cake from the outside to the inside of the filter element, then open the filter backflush valve 6 and the slag discharge valve 9, Instantaneous blowback is performed from the inside to the outside to remove the filter cake, and the filter cake is dischar...

Embodiment 2

[0042] Both the present invention and the existing cluster type backflushing filter deslagging method remove the filter cake by means of gas pressure discharge / drying / backflushing, and the purpose is to collect the filter cake, especially the separation and coalescence group one A. Washing and spraying group II B. Gas-liquid separation and coalescence group III C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com