System and method for preparing H2SO4 from sulfur-containing waste

A technology of H2SO4 and waste materials, applied in chemical instruments and methods, sulfur compounds, ammonia compounds, etc., can solve problems such as odor, corrosion, and serious dust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

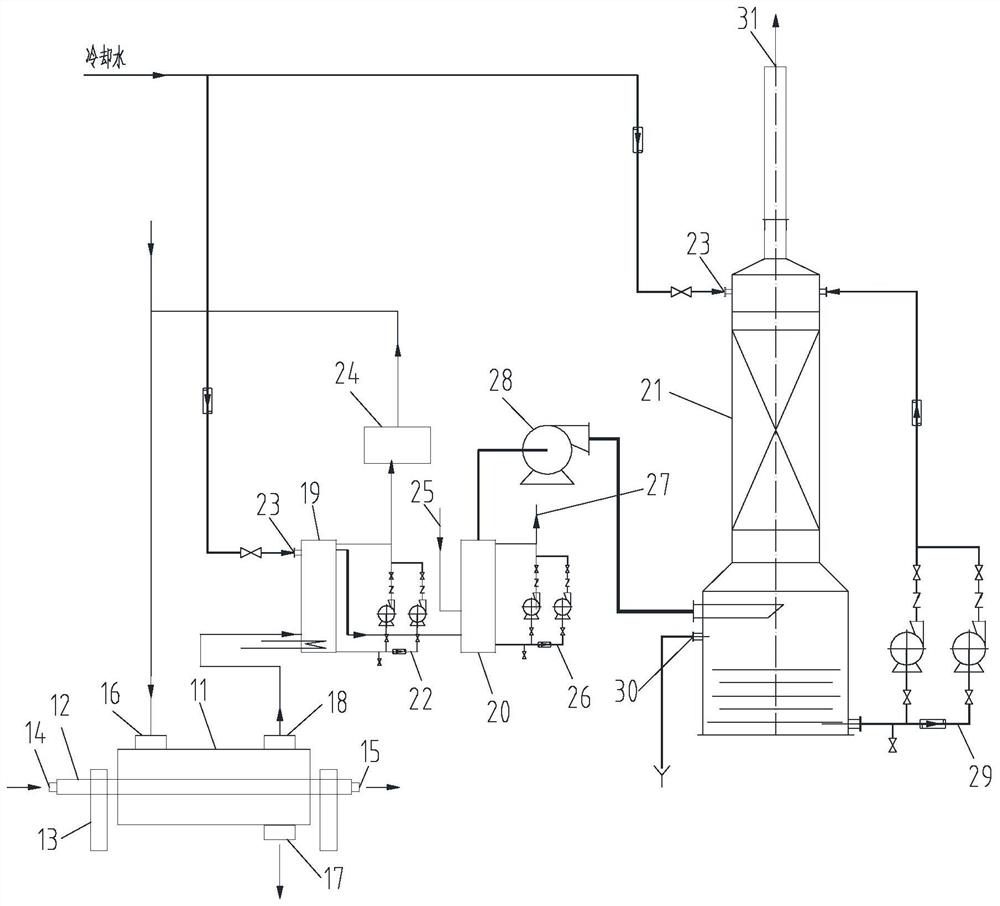

[0096] As an embodiment, the tail gas washing recovery system includes a water washing tower 19, an acid washing tower 20 and a tail gas washing tower 21 connected in sequence; the inlet end of the water washing tower 19 is connected to the tail gas discharge port 18, and the The water washing tower 19 is connected with a water washing circulating pump branch 22 and a cooling water inlet 23 .

[0097] The water washing circulation pump branch 22 includes a first branch connected to the internal circulation of the water washing tower 19 and a second branch connected to the feed inlet of the dryer via a filter bypass system 24 . The filtration bypass system 24 includes a filter, and the outlet of the filter is connected to the feed inlet of the dryer.

[0098] With such a setting, a part of the washing mixture can be used to continue to circulate and wash the tail gas to fully purify the tail gas, and the other part can be used as the raw material liquid for the preparation of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com