Suction nozzle for suction of coarse particles and fine dust

A vacuum cleaner, dust technology, applied in the direction of suction nozzles, vacuum cleaners, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

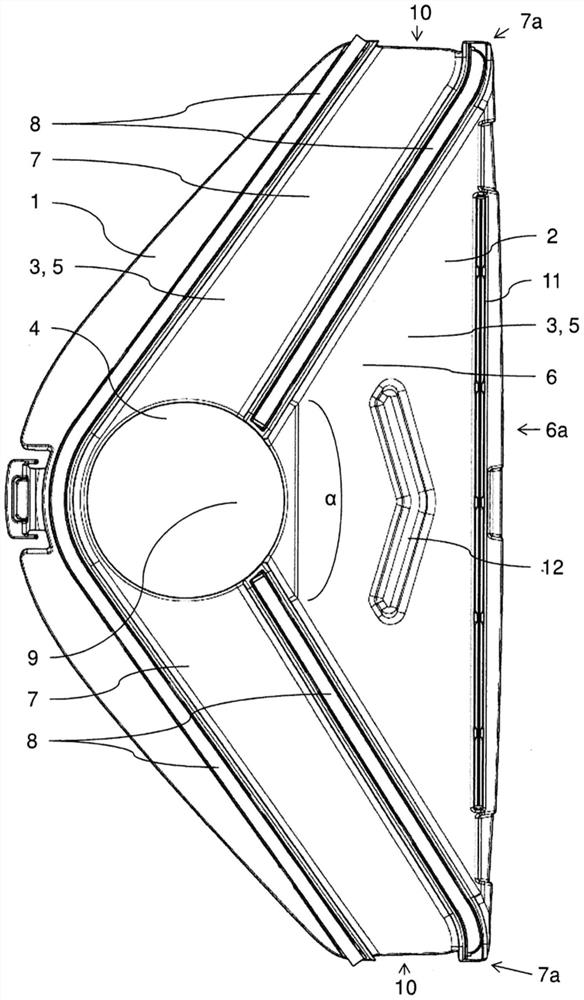

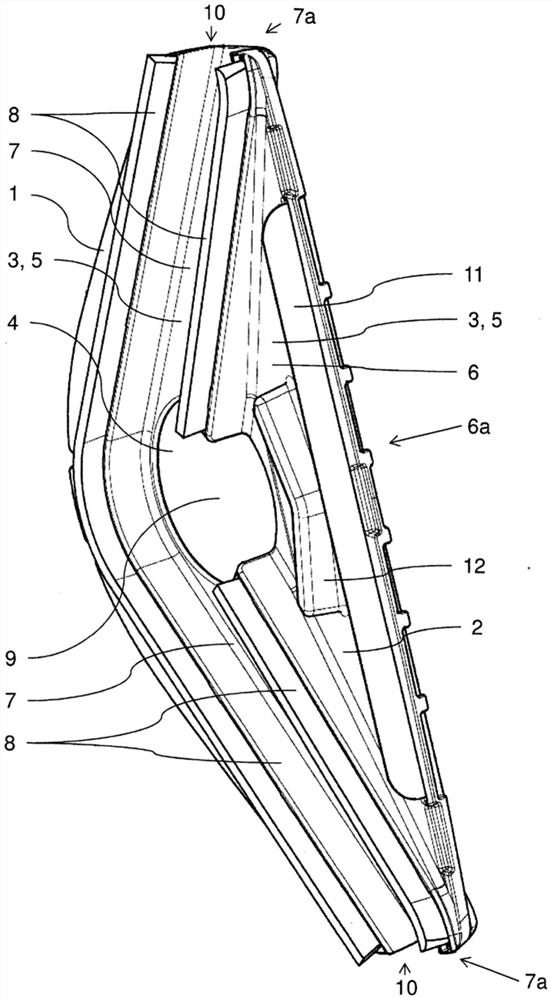

[0022] figure 1 and figure 2 The suction nozzle, also referred to as floor suction nozzle, is shown schematically in a bottom view according to a preferred embodiment of the invention. The suction nozzle has a housing 1 made of plastic, on which a bottom plate 2 is formed on the bottom side. Formed below the base plate 2 is a suction chamber 3 into which the suction channel 4 opens and which forms the suction opening 5 as an opening on the bottom side. as from figure 1 It can be seen that the bottom plate 2 and the suction opening 5 have the shape of an isosceles triangle, the base 6a of which represents the front side of the suction nozzle in the advancing direction.

[0023] The suction channel 4 is connected in a fluid-tight manner to a connecting sleeve (not shown) arranged on the upper side of the housing 1 . On this connecting sleeve, the hand control and / or the flexible hose can be connected in a fluid-tight manner to the basic housing of the vacuum cleaner, in whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com