Hybrid film and preparation method for the same, and flexible OLED displayer

A thin film preparation and hybrid technology, applied in the field of OLED thin films, can solve the problems such as the device cannot be lit, the organic layer has limited water and oxygen blocking effect, and reduces the light extraction efficiency of the device, so as to reduce the sample transmission and vacuuming time, and the overall film The effect of low layer thickness and improved water vapor blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

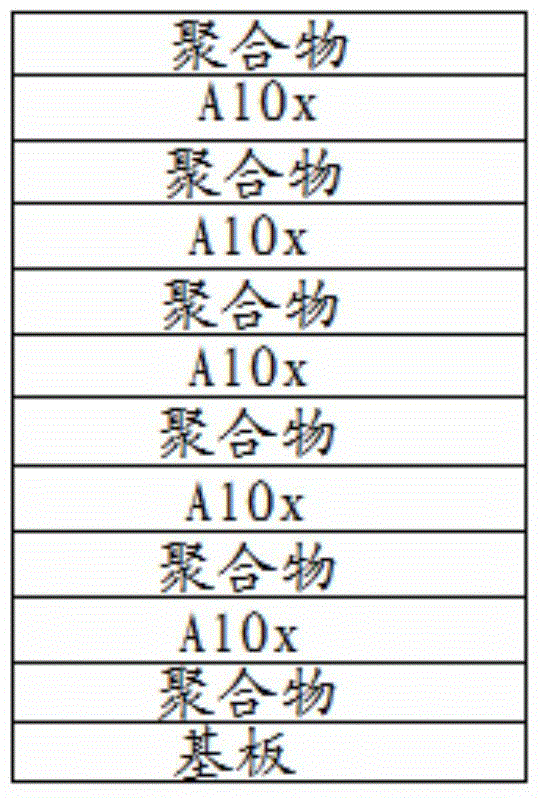

[0048] First see image 3 As shown, a flexible OLED display 20 of the present invention includes a glass bottom plate 21, a flexible substrate 22, a thin film transistor layer 23, an OLED light emitting layer 24, a hybrid film 10, and a flexible cover 25 which are sequentially stacked. The flexible substrate 22 is provided on the upper surface of the glass bottom plate 21, the thin film transistor layer 23 is provided on the upper surface of the flexible cover plate 25, the OLED light emitting layer 24 is provided on the upper surface of the thin film transistor layer 23, and the hybrid film 10 is encapsulated on the OLED light emitting layer On the upper surface of 24, the flexible cover plate 25 is adhered to the upper surface of the hybrid film 10 through an adhesive 26 to form the flexible OLED display 20 of the present invention. Cooperate Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com