Article defect detection system and method based on machine vision

A technology of defect detection and machine vision, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as end surface cracks, size does not meet the requirements, and there is no solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

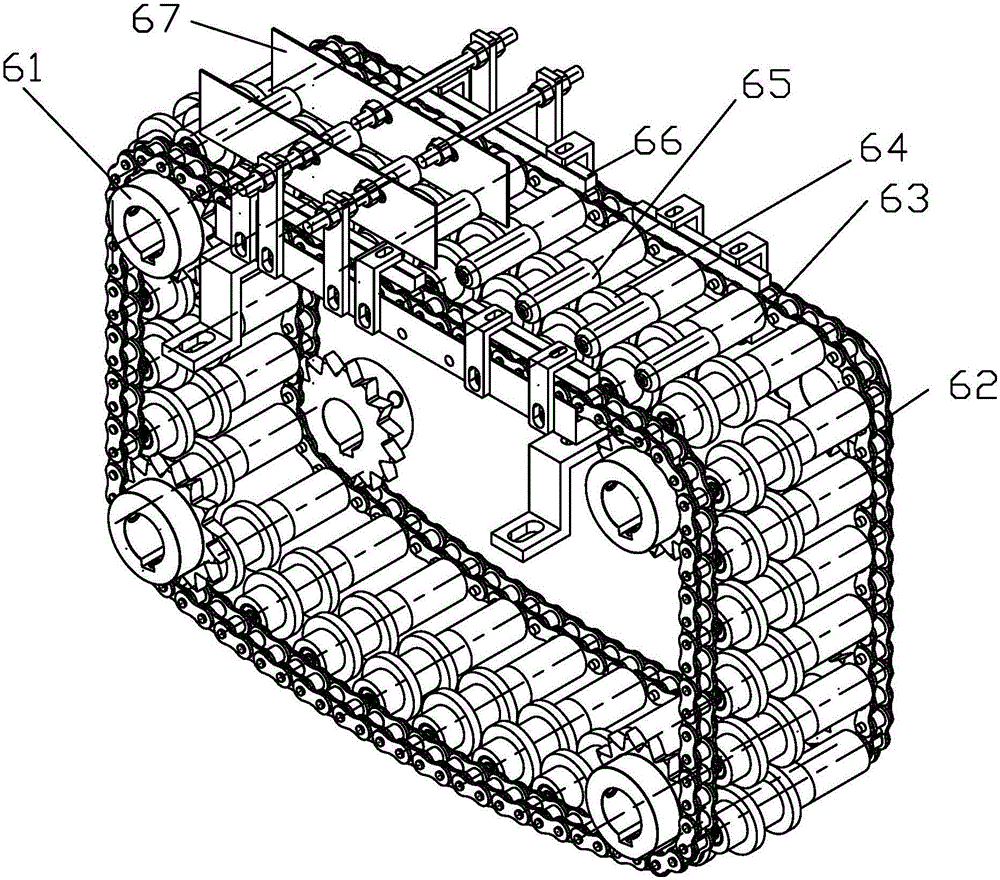

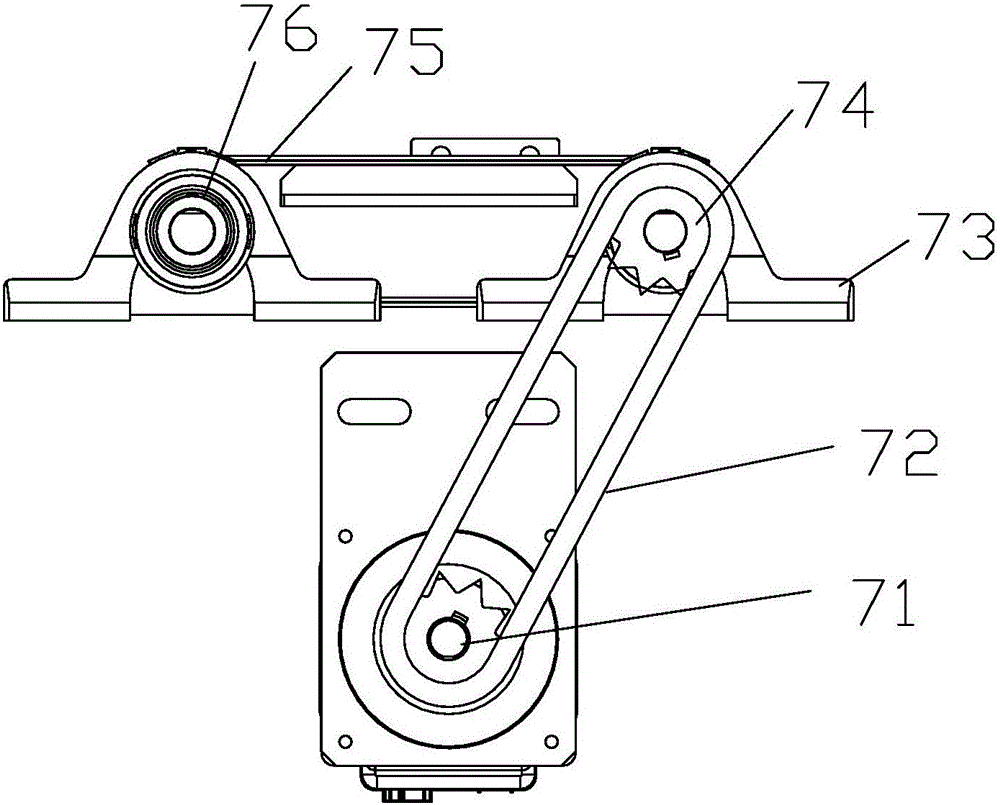

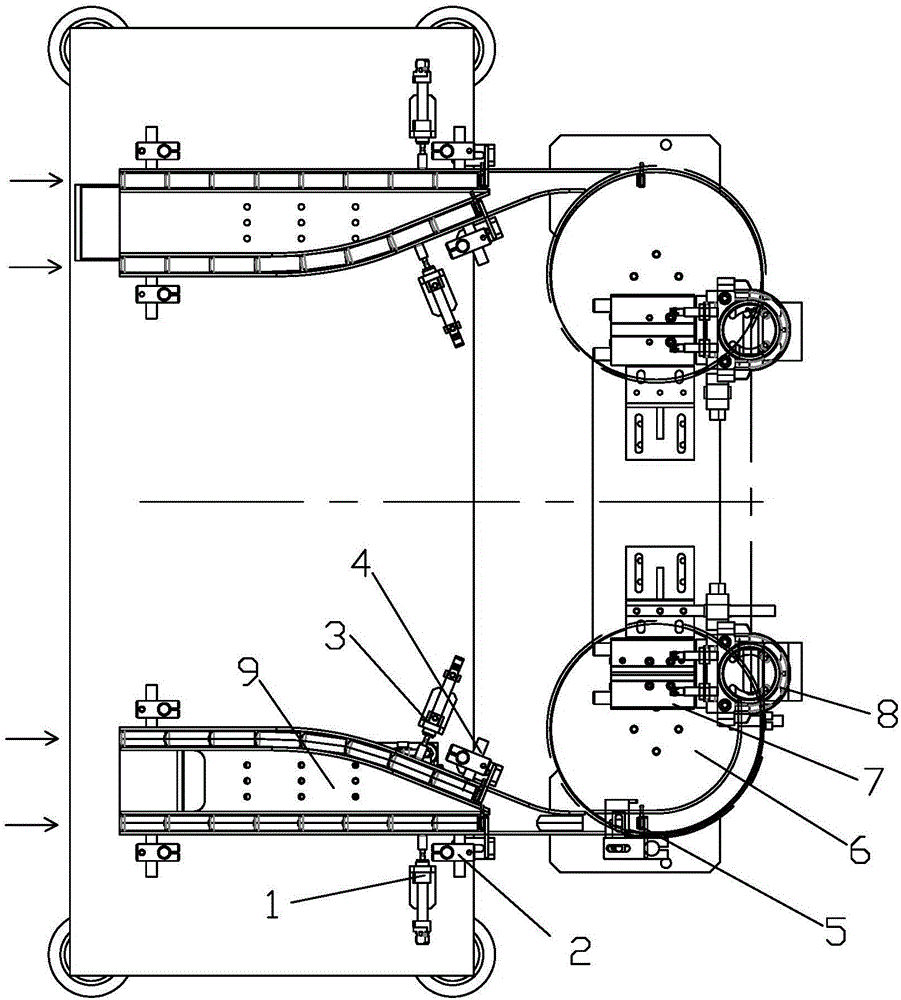

[0104] Embodiment 1: as Figure 1-16 , a machine vision-based article defect detection system includes a frame 80, a feeding device 81, a conveying device 82, an image acquisition device 93, and a control and image processing module;

[0105] The feeding device is docked with the entrance of the conveying device and is installed on the frame. The feeding device is used to transfer the object to be detected to the conveying device; the conveying device is used to send the object to be detected to the detection position;

[0106] The actions of the feeding device and the conveying device are controlled by the control and image processing module;

[0107] An image acquisition device is installed on the frame; the image acquisition device is used to acquire the image of the detected object at the detection position and transmit the image to the control and image processing module for image processing to determine whether the corresponding object to be inspected has defects. Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com