Dust sensor based on continuous transformation barrier layer

A technology of dust sensor and barrier layer, which is applied in the electronic field, can solve the problem of sensor being polluted and polluted, and achieve the effect of avoiding direct contact with smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

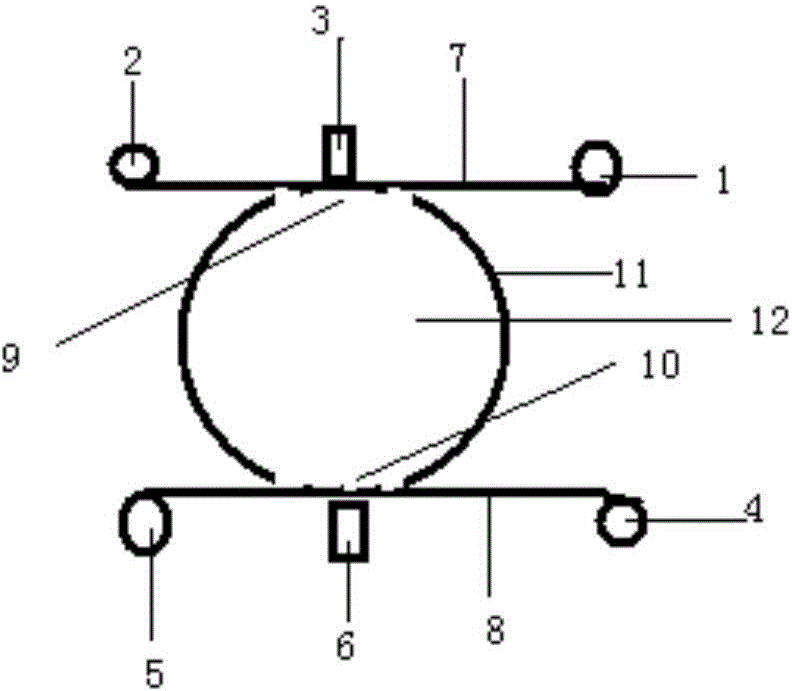

[0015] exist figure 1 Among them, the upper film rotating shaft 1 is connected with the above rotating shaft 2 through the upper film 7, and the infrared sensor 3 passes through the upper film 7, the upper opening 9, the sampling flue 12, the lower opening 10, and the lower film 8, and is the same as the infrared light-emitting tube 6 The upper opening 9 and the lower opening 10 are connected with the sampling flue wall 11, and the lower membrane rotating shaft 4 is connected with the lower membrane driven shaft 5 through the lower membrane 8.

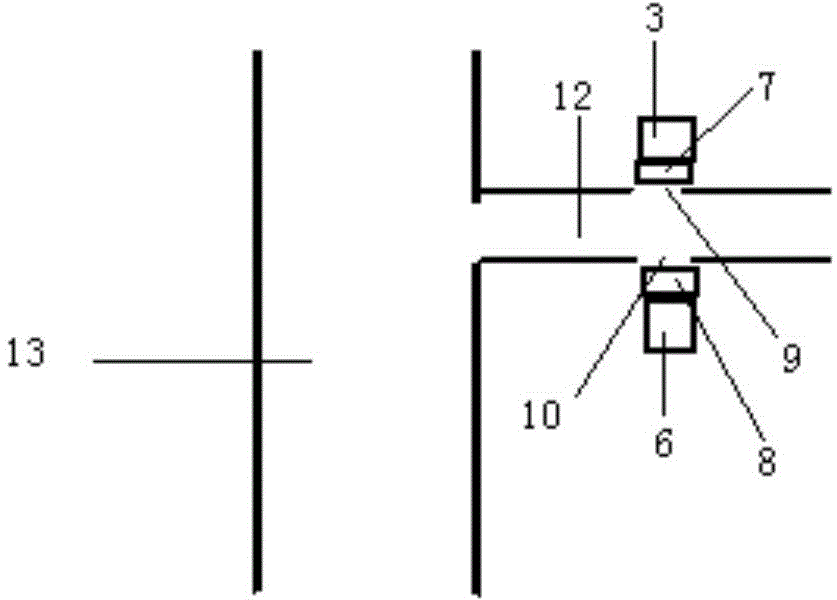

[0016] exist figure 2 In the shown embodiment, the sampling flue 12 is connected to the flue 13, and the infrared sensor 3 is connected to the infrared light-emitting tube 6 through the upper film 7, the upper opening 9, the sampling flue 12, the lower opening 10, and the lower film 8.

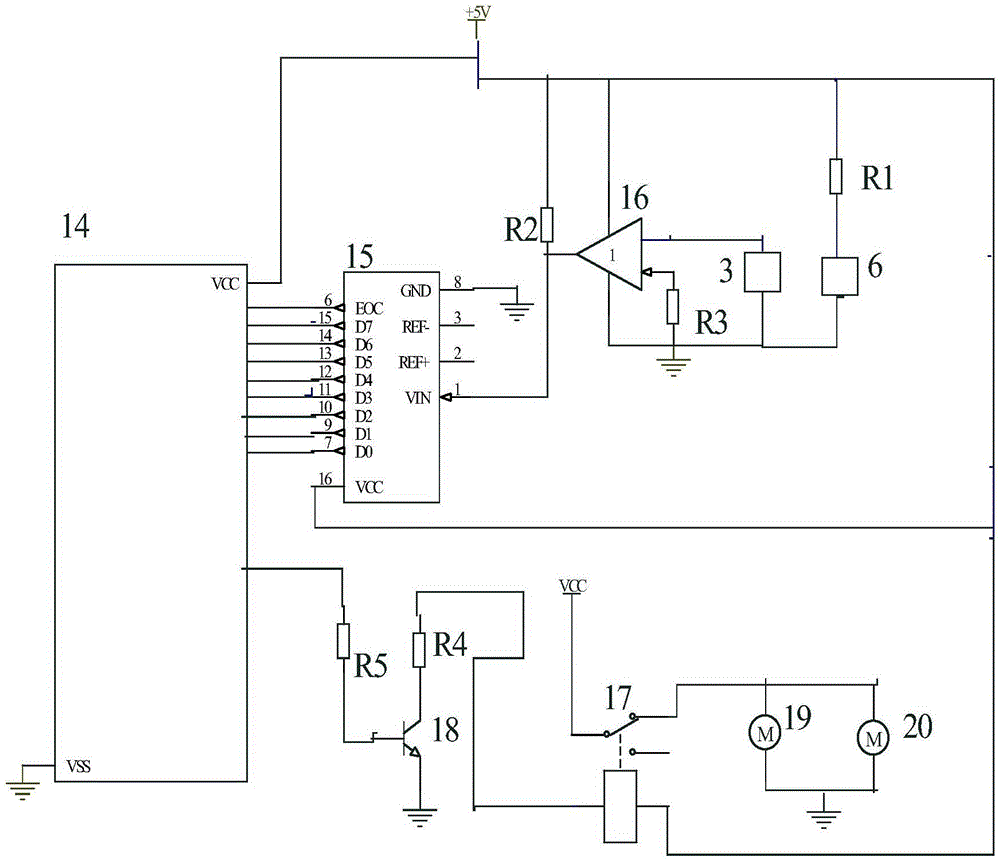

[0017] exist image 3 In the shown embodiment, the infrared light-emitting tube 6 is connected with the resistor R1, the infrared sensor 3 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com