Rapid leakage detection method for copper pipe in lithium bromide refrigerating machine chamber

A refrigerator and lithium bromide technology, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems that ordinary workers are difficult to master, labor intensity is high, and special equipment is complicated. Achieve the effect of improving detection work efficiency, reducing labor intensity and saving maintenance funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

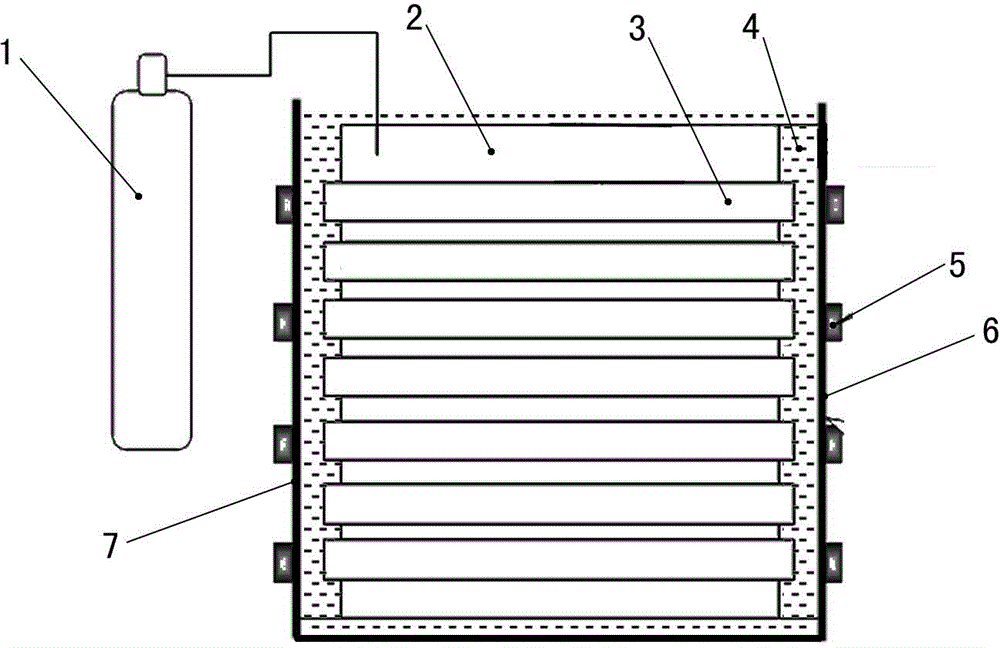

[0010] Further description will be made below in conjunction with the accompanying drawings.

[0011] Replace the original steel inspection door on the shell 7 containing the heat exchange chamber 2 of the lithium bromide refrigerator with a transparent material door, that is, a glass inspection door assembled from a glass plate 6 and an angle steel 5 frame, and install sealing strips around the edges of the inspection door . Then, clean water 4 is filled between the shell 7 and the heat exchange cavity 2 of the refrigerator, and nitrogen gas with a pressure higher than water pressure is charged into the heat exchange cavity 2, and the nitrogen pressure is 0.1-0.3 MPa. If the heat exchange copper tube 3 is damaged, the gas can pass through the leakage point on the heat exchange copper tube 3 under pressure, and the inspector can visually observe the leaking heat exchange copper tube 3 with air bubbles through the transparent door. The leakage location can be quickly determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com