A spray-swirl stacking multi-point incoming material recycling type decomposition furnace

A decomposition furnace and recirculation technology, applied in furnaces, vertical furnaces, furnace types, etc., to achieve the effects of increasing decomposition rate, eliminating system crust, and reducing initial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

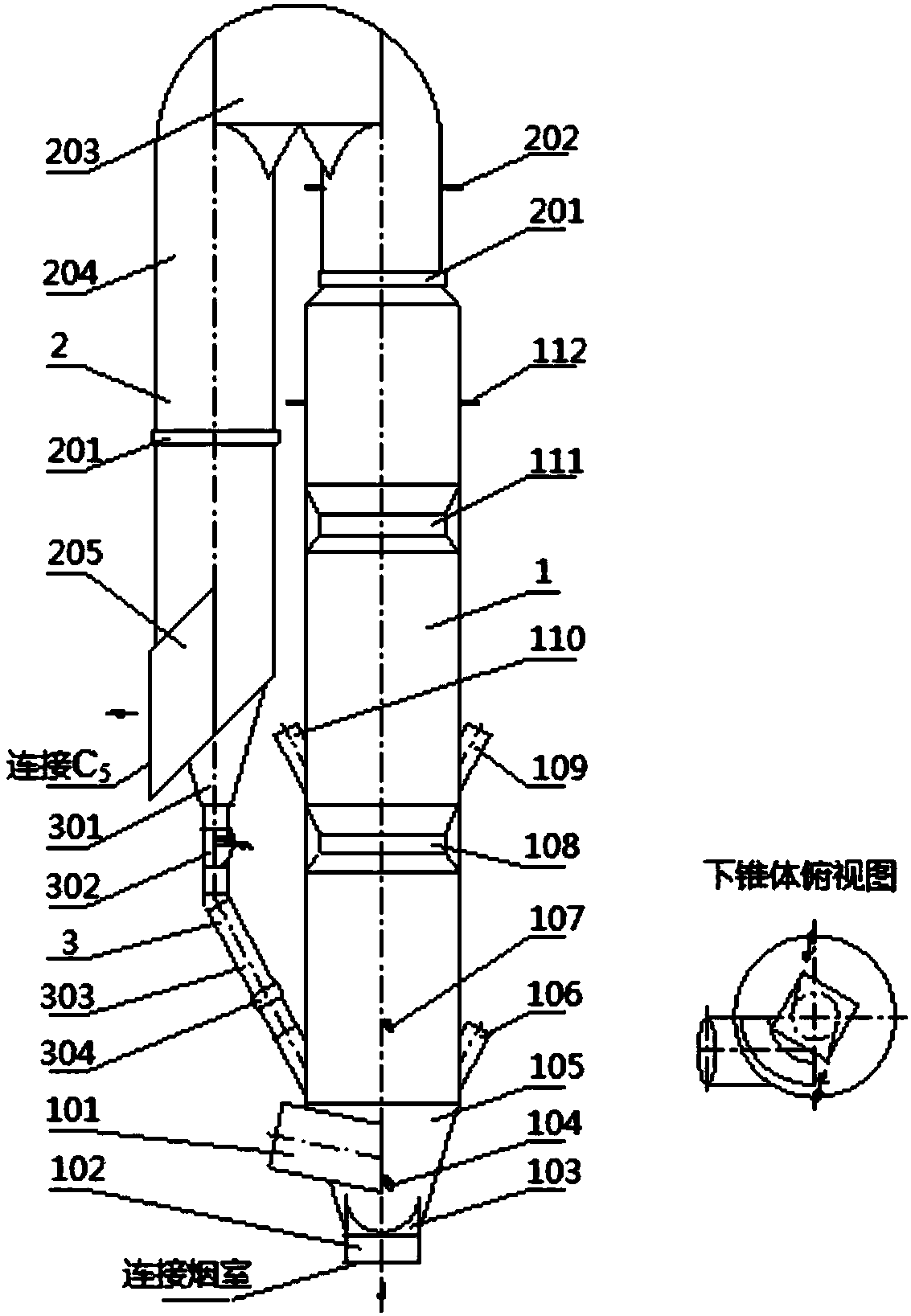

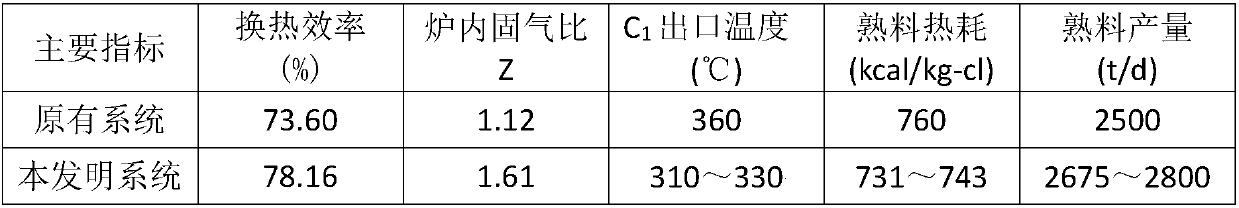

[0045] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

[0046] The lowest level cyclone of the cyclone preheater system mentioned in the present invention refers to the lowest level of cyclone arranged from top to bottom in the cyclone preheater system, which is C 4 , for a 5-stage cyclone preheater is C 5 , for a 6-stage cyclone preheater is C 6 . The so-called penultimate cyclone of the preheater system refers to the penultimate cyclone arranged from top to bottom at all levels of the cyclone preheater system. For a 4-stage cyclone preheater, it is C 3 , for a 5-stage cyclone preheater is C 4 , for a 6-stage cyclone preheater is C 5 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com