Air conditioner heating unit and heating control method thereof

A technology of unit and heat exchange tube group, applied in refrigerators, heating methods, air conditioning systems, etc., can solve the problems of continuous heating operation, slow room temperature increase, and affecting the service life of compressors, etc., and achieve the effect of waste heat recovery Good, uniform air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

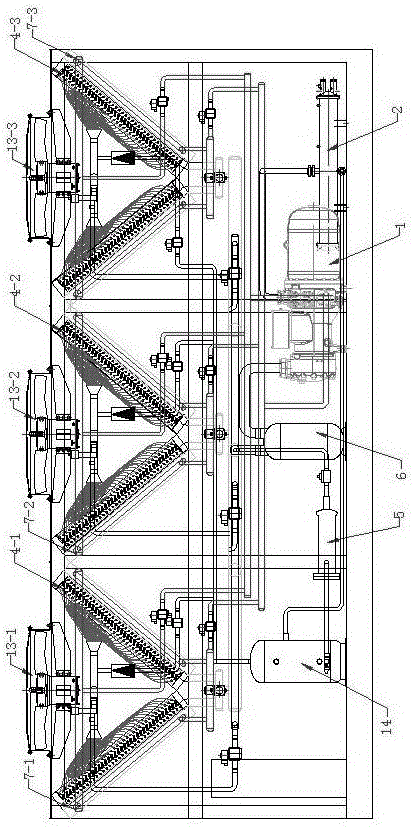

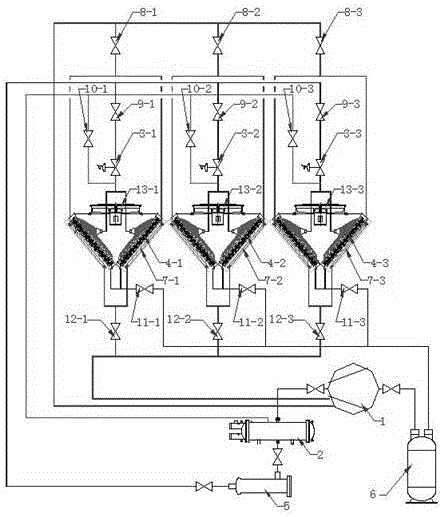

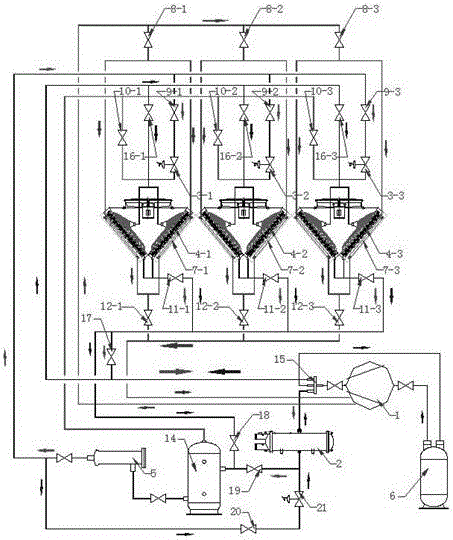

[0030] The air-conditioning and heating unit of the present invention includes a compressor, an evaporator, an expansion valve, and a condenser, and forms a circuit in sequence. A throttle valve and a liquid supply valve are arranged between the condenser and the evaporator, and a fan is arranged above the evaporator. A lubricating oil heat exchange tube group is arranged below, and a high-pressure gas defrosting valve is arranged between the condenser and the evaporator. At least two groups of evaporators are provided, and three groups of evaporators are provided in this embodiment, and the specific scheme is as follows:

[0031] As shown in 2, the working principle of heating operation: For example: during heating operation in winter, the throttle valves 3-1, 3-2, 3-3 of the evaporators 4-1, 4-2, 4-2 Valves 9-1, 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com