Internal reinforced type composite pipe

A composite pipe, reinforced technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of unfavorable laying and construction, poor toughness of pipes, large bending radius, etc., to achieve long service life and improve resistance. Good effect under pressure and durability, toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

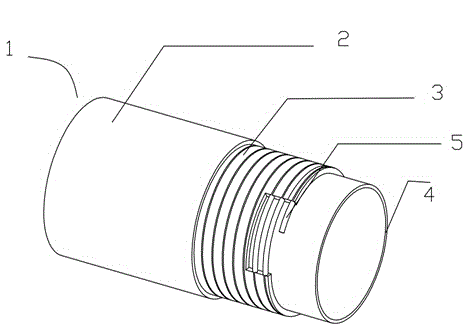

[0014] Such as figure 1 As shown, the internally reinforced composite pipe 1 includes a tubular outer layer 2 and a tubular inner layer 4, an intermediate layer 3 is arranged between the outer layer 2 and the inner layer 4, and the intermediate layer 3 is braided by chemical fibers. A network structure is formed, and a reinforcing layer 5 made of nylon filament helical structure is embedded in the middle layer 3 .

[0015] Both the outer layer 2 and the inner layer 4 are made of polyurethane resin, and the middle layer 3 is a mesh structure woven from polyester filaments.

[0016] Of course, the middle layer 3 can also be woven by other fibers, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com