A large flow high pressure variable pump oil inlet valve

An oil inlet valve, variable pump technology, applied in the direction of fuel injection pump, charging system, fuel injection device, etc., can solve problems such as pressure fluctuation and hydraulic shock, and achieve the effect of satisfying demand, easy implementation and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0029] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

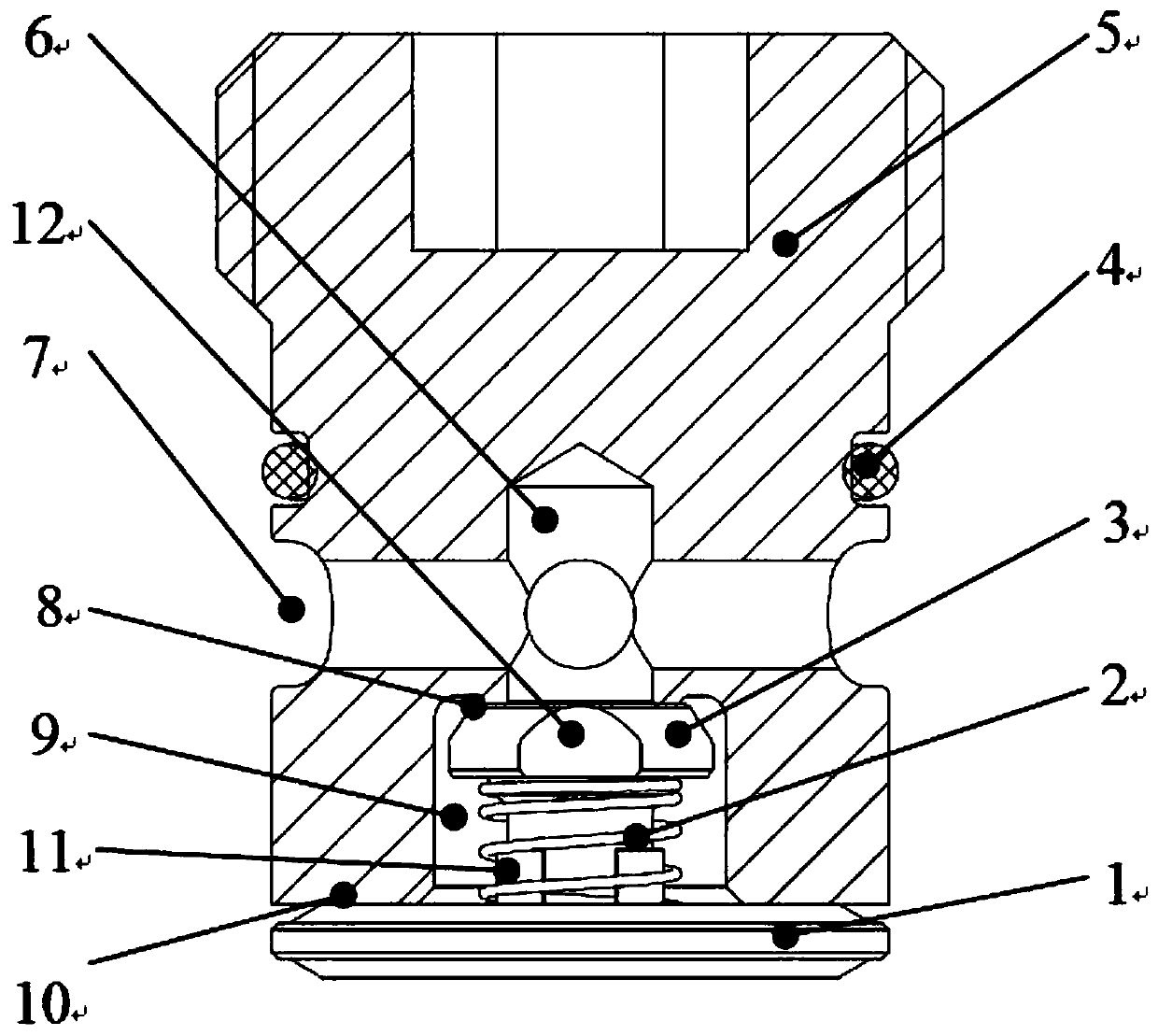

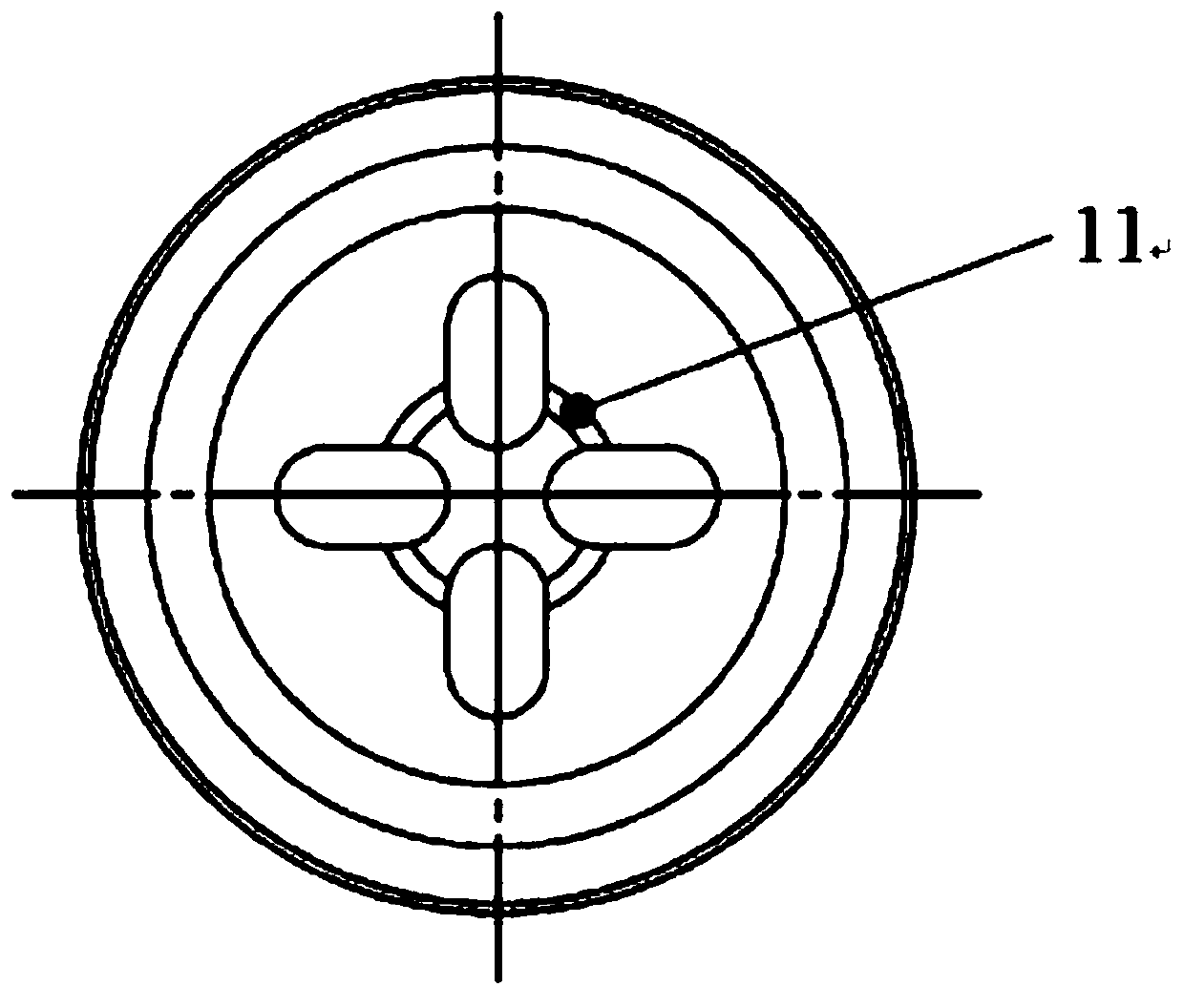

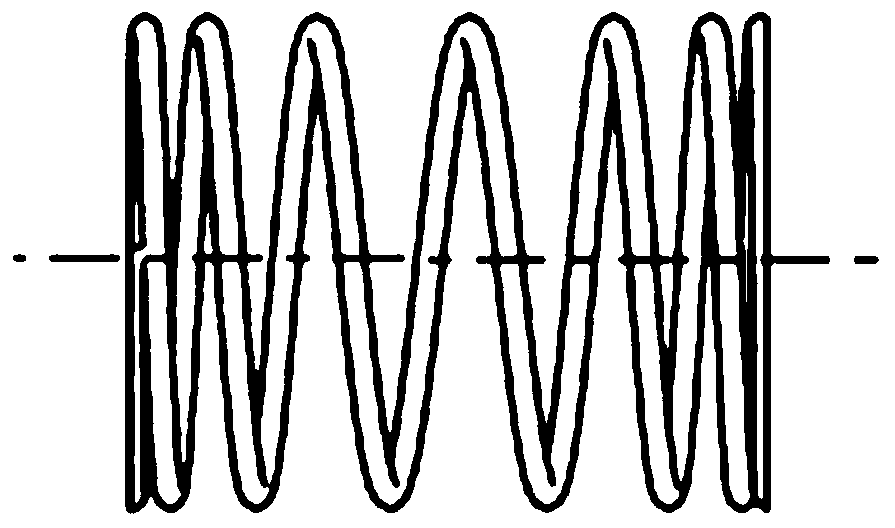

[0030] In the embodiment of the present invention, the oil inlet valve of the large flow and high pressure variable pump, such as Figures 1 to 6 shown, including base 1, spring 2, valve block 3, O-ring 4 and inlet valve body 5,

[0031] The oil inlet valve body 5 is provided with the oil inlet valve upper chamber 6 and the oil inlet valve lower chamber 9, the valve block 3 is arranged in the oil inlet valve lower chamber 9, and the upper surface of the valve block 3 is connected to the oil inlet valve. The valve block sealing surface 8 is formed where the top surface of the lower chamber 9 contacts; the bottom surface of the valve block 3 is gap-fitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com