Vehicle-mounted compressor

A compressor, an integrated technology, applied in the field of compressors, can solve the problems of high cost, inconvenience, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

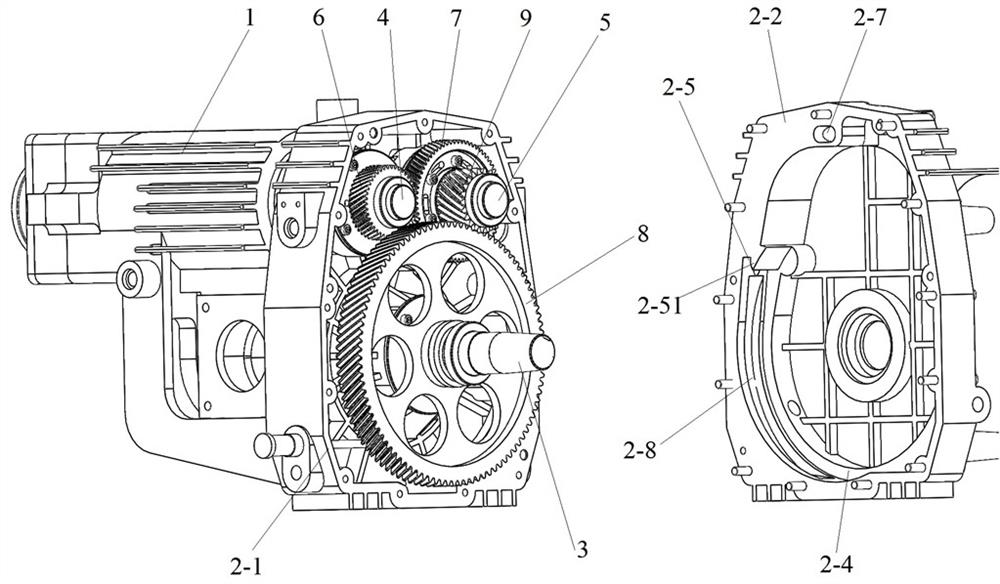

[0024] Such as figure 1 As shown in , the vehicle-mounted compressor of the present invention includes a cylinder 1, a gear box and a main shaft 3, the cylinder 1 is provided with a rotor I4 and a rotor II5, and the gear box is provided with a gear I6, a gear II7, a gear III8, a gear IV9, and a rotor I4 One end of rotor Ⅱ5 and rotor Ⅱ5 both extend into the gearbox, rotor Ⅰ4 is connected with gear Ⅰ6 in the gearbox, rotor Ⅱ5 is connected with gear Ⅱ7 and gear Ⅳ9 in the gearbox, and the main shaft 3 also extends into the gearbox and is in the gearbox It is connected with gear III8, gear III8 is meshed with gear IV9, and gear I6 is meshed with gear II7. The main shaft 3 is driven by an external drive source to drive the gear III8 to rotate, and the gear III8 meshes with the drive gear IV9 to rotate, and the rotor II5 rotates synchronously with the gear IV9 to make the gear II7 drive the gear I6 to rotate, so that the rotor I4 rotates synchronously with the gear I6. Main shaft 3 ...

Embodiment 2

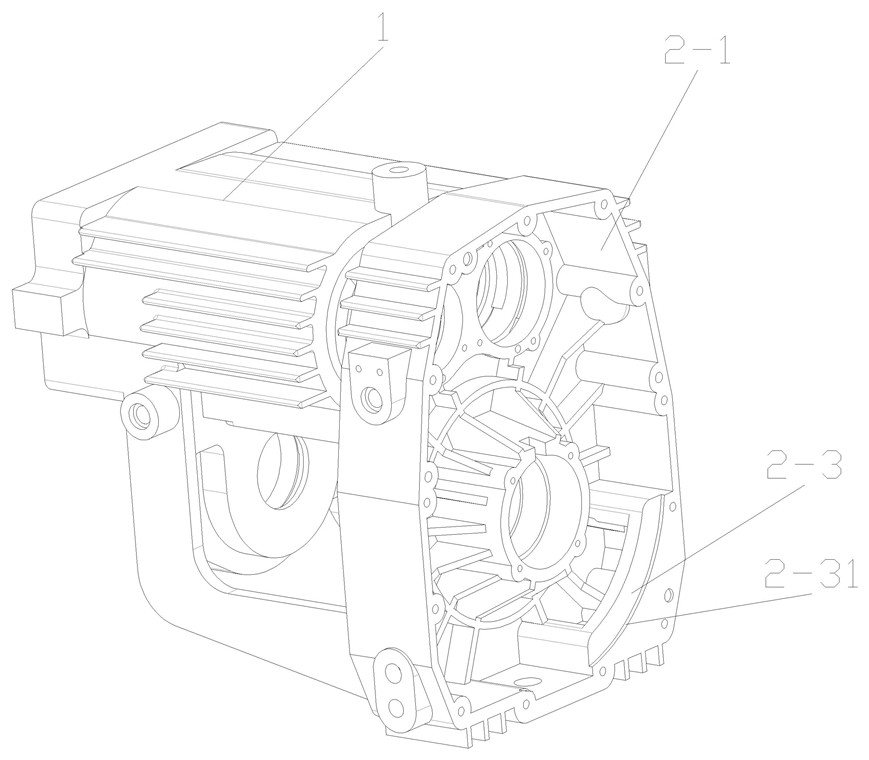

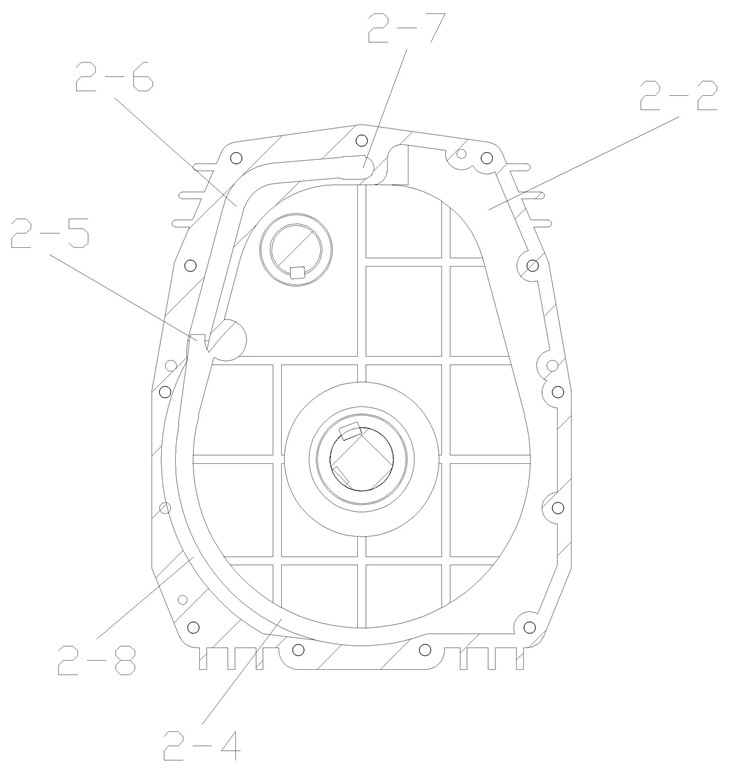

[0028] The difference between the vehicle-mounted compressor in this embodiment and Embodiment 1 is that an oil baffle 2-3 is provided on the middle and lower part of the inner wall of the box body 2-1, and the oil baffle plate 2-3 is integrally formed with the box body 2-1 cast, such as figure 2 shown in . Such as figure 1 , image 3 with Figure 4As shown in , the side of the cover body 2-2 corresponding to the oil baffle plate 2-3 is provided with an oil baffle wall 2-4, and the oil baffle wall 2-4 is located at the middle and lower part of the inner side wall of the cover body 2-2 and is connected with the The oil baffle 2-3 is opposite, and the oil baffle 2-4 and the oil passage 2-6 are integrally molded and cast with the cover 2-2, and the oil baffle 2-3, the oil baffle 2-4 and the cover 2- 2, the inner wall corresponding to the oil retaining wall 2-4 forms an oil retaining groove, the middle and lower part of the gear III 8 side and the oil guide groove 2-8 are loc...

Embodiment 3

[0031] The difference between the vehicle-mounted compressor of this embodiment and Embodiment 2 is that the side of the oil baffle 2-3 opposite to the cover 2-2 is also provided with an arc-shaped step surface 2-31, such as figure 2 As shown in , after the box body 2-1 and the cover body 2-2 are assembled left and right, the oil baffle plate 2-3 and the oil baffle wall 2-4 are respectively the groove walls of the oil baffle groove, and the arc-shaped step surface 2-31 The inner side wall corresponding to the oil retaining wall 2-4 in the cover body 2-2 is combined to form the groove bottom of the oil retaining groove, so that the width of the oil retaining groove is widened, and the gear III8 in the gear box is reduced. difficulty of assembly. The arc-shaped stepped surface 2-31 can be integrally molded and cast with the box body 2-1, or can be processed by turning or milling on the oil baffle plate 2-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com