Oil well pump for well washing

An oil pumping and well cleaning technology, applied in the direction of pumps, pump components, and parts of pumping devices for elastic fluids, etc. Efficiency of oil intake, improvement of filling degree, effect of improving filling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

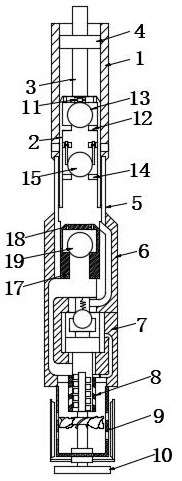

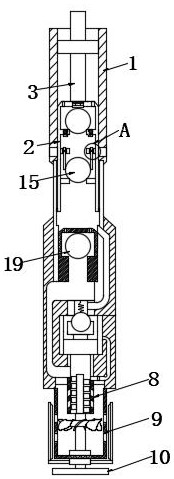

[0023] Example 1: See Figure 1-8 As shown, the present invention is an oil well pump for well cleaning, which includes a pump cylinder 1. An extended plunger 2 is slidably connected to the inside of the pump cylinder 1, and an oil pulling rod 3 is fixedly connected to the upper surface of the extended plunger 2. By reciprocating pulling Pull the oil rod 3, so that the oil pull rod 3 drives the extended plunger 2 to reciprocate up and down inside the pump barrel 1, and a guide mechanism 4 is arranged outside the pump barrel 1 outside the oil pull rod 3, and the pump barrel 1 The lower end of the upper joint 5 is fixedly connected with the upper joint 5, and the lower end of the upper joint 5 is fixedly connected with the thick tube 6, and the end of the thick tube 6 away from the upper joint 5 is fixedly connected with the oil drain mechanism 7, and the lower end of the oil drain mechanism 7 is fixedly connected with the oil inlet tube 8, and the oil inlet cylinder 8 and the c...

Embodiment 2

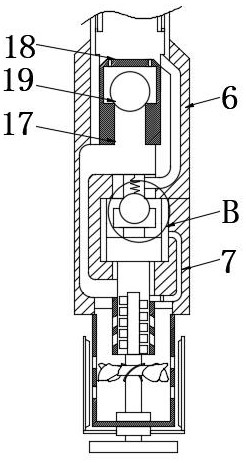

[0024] Embodiment 2: The internal rotation of the sand control cylinder 9 is connected with a cleaning assembly 10, and the cleaning assembly 10 includes a driven shaft 101, and a driven fan 102 is sleeved on the outside of the driven shaft 101. As the equipment performs an upstroke, the crude oil From the sand control cylinder 9 to the inside of the oil inlet cylinder 8, the crude oil has fluidity, and then the crude oil drives the driven fan 102 outside the driven shaft 101 to rotate during the flow, and the lower end of the driven shaft 101 is fixedly connected with The base 104 and the outside of the driven shaft 101 are sleeved with a positioning sleeve 103, and the positioning sleeve 103 is movably connected with the sand control cylinder 9, and when the driven fan 102 drives the driven shaft 101 to rotate, the driven shaft 101 drives the positioning The shaft sleeve 103 then rotates, and then generates the power of the transmission, and the two sides of the positioning s...

Embodiment 3

[0025] Embodiment 3: When cleaning the equipment, the extended plunger 2 is taken out from the inside of the pump barrel 1 through the oil rod 3, and then the inside of the pump barrel 1 is pressed. As the internal pressure of the pump barrel 1 is constantly changing large, and then the pressure above the oil drain mechanism 7 is greater than the pressure below, and the oil drain mechanism 7 includes the oil drain tube 01, and the inside of the oil drain tube 01 is fixedly connected with the fixed rod 02, and the inside of the oil drain tube 01 is located in the fixed plug ball The top of 04 is fixedly connected with return pipe 06, the upper end of fixed rod 02 is sleeved with telescopic rod 03, and the side of telescopic rod 03 away from fixed rod 02 is fixedly connected with fixed blocking ball 04 inside, and the upper surface of fixed blocking ball 04 is fixed Connect the limit spring 05, the end of the limit spring 05 away from the fixed ball 04 is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com