Alcoholysis method in the preparation process of a kind of ethylene-vinyl alcohol copolymer

A vinyl acetate copolymer and a technology for a preparation process are applied in the field of preparation of ethylene-vinyl alcohol copolymers, and can solve the problems of increasing the complexity of EVOH production process, uncontrollable alcoholysis reaction speed, increasing EVOH preparation process, and the like, and reducing the Coloring phenomenon, improve alcoholysis effect, reduce equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of alcoholysis method in the preparation process of ethylene-vinyl alcohol copolymer, it is specifically carried out according to the following steps:

[0031] 1) Purification and deployment of alcoholysis raw materials

[0032] The alcoholysis raw material adopts the polymerization reaction product obtained directly from the EVOH preparation process by the polymerization reaction of ethylene and vinyl acetate. After testing, the alcoholysis raw material is composed of 25 parts of ethylene-vinyl acetate copolymer in parts by weight. , 45 parts of vinyl acetate, 30 parts of solvent and 1 part of impurities; the alcoholysis raw material is heated to 70°C to evaporate impurities such as VAC, solvent and water, and methanol is added for solvent replacement until the VAC content in the alcoholysis raw material is 0.1wt%, and the water content is 0.05wt%; then add methanol for deployment to obtain an ethylene-vinyl acetate copolymer solution with a content of 10wt%;

...

Embodiment 2

[0038] A kind of alcoholysis method in the preparation process of ethylene-vinyl alcohol copolymer, it is specifically carried out according to the following steps:

[0039] 1) Purification and deployment of alcoholysis raw materials

[0040] The alcoholysis raw material adopts the polymerization reaction product obtained directly from the EVOH preparation process by the polymerization reaction of ethylene and vinyl acetate. After testing, the alcoholysis raw material is composed of 40 parts of ethylene-vinyl acetate copolymer in parts by weight. , 45 parts of vinyl acetate, 15 parts of solvent and 1 part of impurities; the alcoholysis raw material is heated to 75°C, and ethanol is added for solvent replacement, so that the VAC content in the alcoholysis raw material is 0.5wt%, and the water content is 0.1wt %; Then add ethanol and prepare, and obtain the ethylene-vinyl acetate copolymer solution that content is 30wt%;

[0041] 2) Preparation of catalyst solution

[0042] Po...

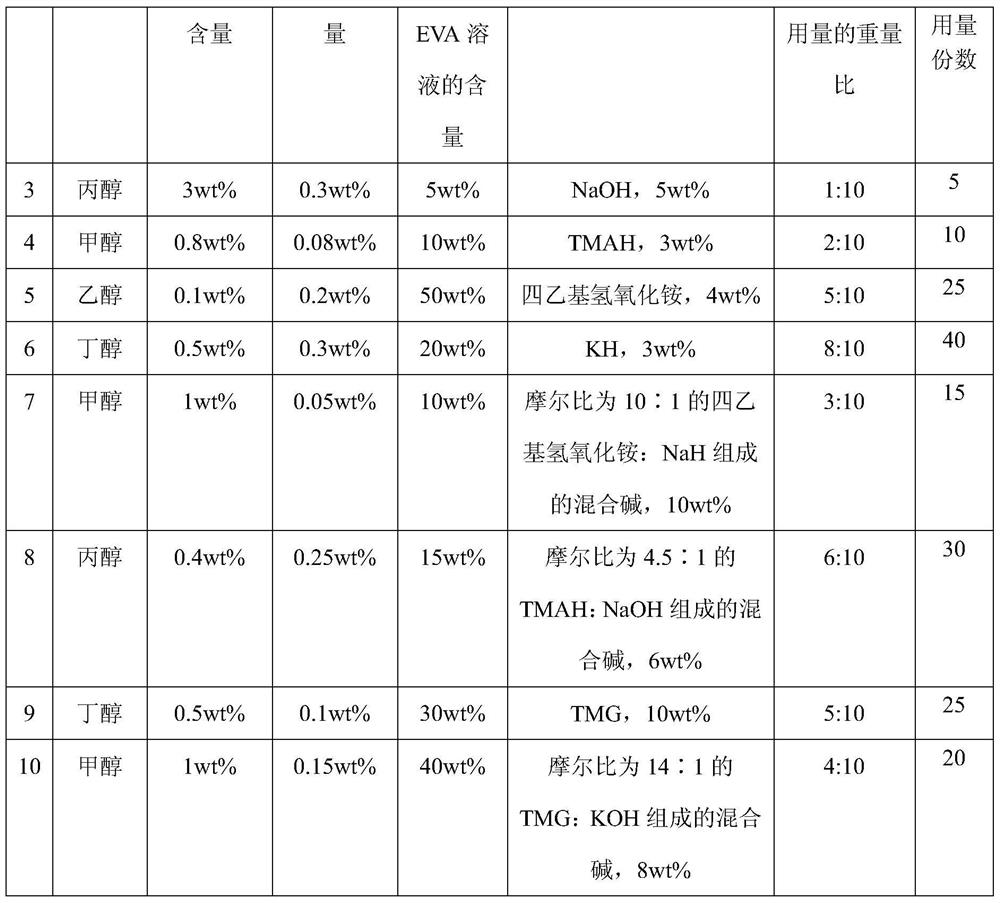

Embodiment 3-10

[0046] Embodiment 3-10 is carried out by following materials, technique and parameter, and all the other settings are all the same with embodiment 2:

[0047]

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com