Light high-strength mullite-quartz porous brick and preparation technology thereof

A preparation process and technology for porous bricks, which are applied in the fields of resources, environment and building materials, can solve the problems of reducing the service life of coal gangue bricks, insufficient porosity of coal gangue bricks, low brick strength, etc., achieving significant economic and environmental benefits, eliminating the need for Numerous environmental concerns, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

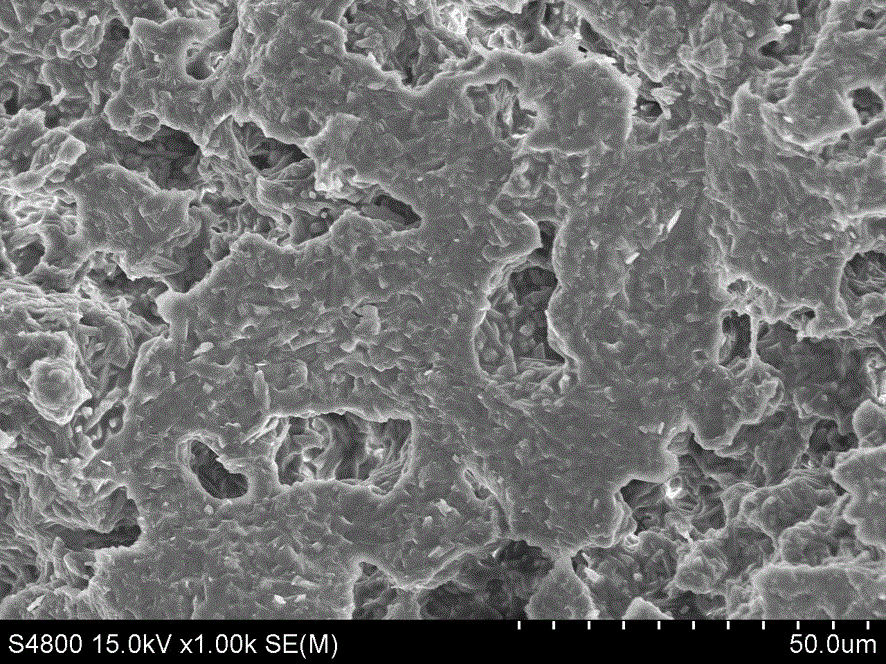

[0028] Such as figure 1 Shown, a kind of lightweight high-strength mullite-quartz porous brick, it comprises coal gangue, burnt gemstone and bauxite, wherein the raw material of said brick is composed of coal gangue, burnt gemstone, bauxite, fly ash and Clay, wherein the weight percentage content of each raw material is: coal gangue 50%, burnt gem 20%, bauxite 5%, fly ash 15%, clay 10%.

[0029] In this embodiment one, the coal gangue raw material composition and its weight percentage content are: Al 2 o 3 The content is 23%, SiO 2 The content is 65%, K 2 O content is 5%, Fe 2 o 3 The content is 5%, and the remaining unavoidable impurities are 2%.

[0030] In this embodiment one, the bauxite raw material composition and its weight percent content are: Al 2 o 3 The content is 60%, SiO 2 The content is 26%, Fe 2 o 3 The content is 8%, TiO 2 The content is 5%, and the remaining unavoidable impurities are 1%.

[0031] The process of preparing lightweight high-strength...

Embodiment 2

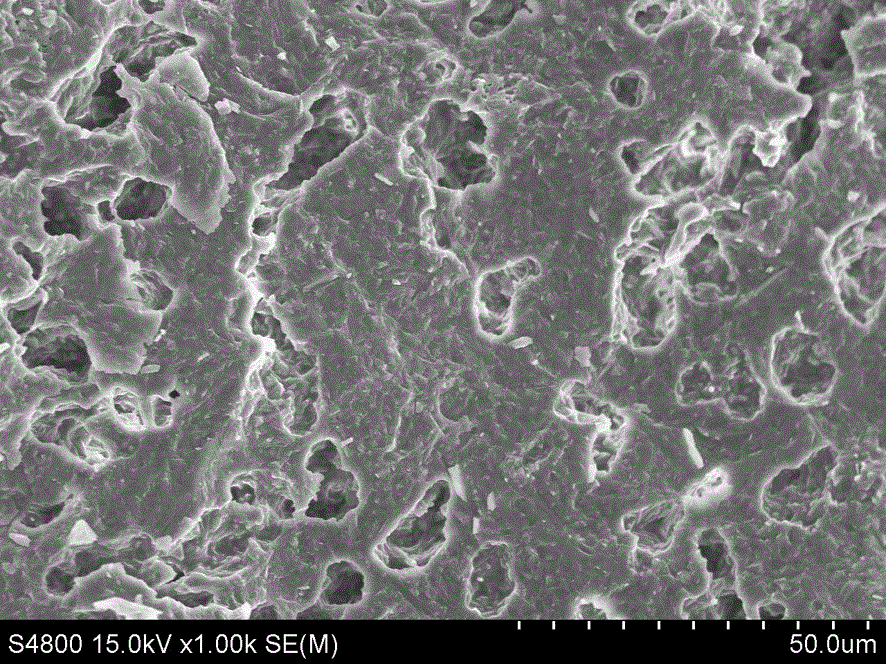

[0040] Such as figure 2 Shown, a kind of lightweight high-strength mullite-quartz porous brick, it comprises coal gangue, burnt gemstone and bauxite, wherein the raw material of said brick is composed of coal gangue, burnt gemstone, bauxite, fly ash and Clay, wherein the weight percentage content of each raw material is: coal gangue 54%, burnt gemstone 16%, bauxite 5%, fly ash 14%, clay 11%.

[0041] In the present embodiment two, the coal gangue raw material composition and its weight percentage content are: Al 2 o 3 The content is 24.5%, SiO 2 The content is 64.8%, K 2 O content is 4.3%, Fe 2 o 3 The content is 4.7%, and the remaining unavoidable impurities are 1.7%.

[0042] In this embodiment two, the bauxite raw material composition and its weight percent content are: Al 2 o 3 The content is 61.5%, SiO 2 The content is 25.6%, Fe 2 o 3 The content is 7.4%, TiO 2 The content of other unavoidable impurities is 4.7%, and the content of other unavoidable impuritie...

Embodiment 3

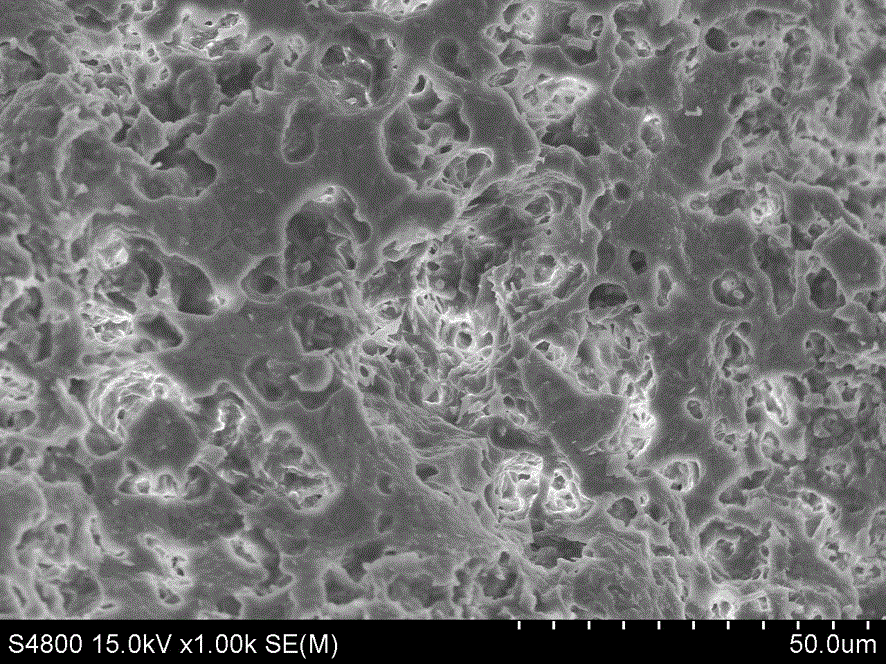

[0051] Such as image 3 Shown, a kind of lightweight high-strength mullite-quartz porous brick, it comprises coal gangue, burnt gemstone and bauxite, wherein the raw material of said brick is composed of coal gangue, burnt gemstone, bauxite, fly ash and Clay, wherein the weight percentage content of each raw material is: coal gangue 60%, burnt gem 15%, bauxite 5%, fly ash 12%, clay 8%.

[0052] In the present embodiment three, the coal gangue raw material composition and its weight percentage content are: Al 2 o 3 The content is 25%, SiO 2 The content is 65%, K 2 O content is 4.7%, Fe 2 o 3 The content is 4.3%, and the remaining unavoidable impurities are 1%.

[0053] In the present embodiment three, the bauxite raw material composition and its weight percent content are: Al 2 o 3 The content is 62%, SiO 2 The content is 23%, Fe 2 o 3 The content is 9%, TiO 2 The content is 5%, and the content of other unavoidable impurities is 1%.

[0054] The process of preparin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com