Comprehensive treatment technology of farming excrement and mulching film non-point source pollution

A comprehensive treatment and sewage technology, applied in water/sludge/sewage treatment, sludge treatment, biological water/sewage treatment, etc., to shorten engineering time, save civil construction costs, and avoid secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

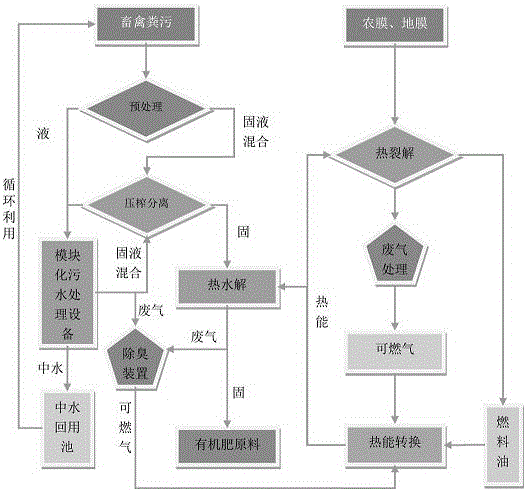

[0033] Examples, as attached figure 1 As shown, a comprehensive treatment process for aquaculture manure and agricultural plastic film non-point source sewage comprises the following steps:

[0034] First, manure pretreatment; after the manure flows into the adjustment tank, add cationic polyacrylamide flocculant according to the proportion of 0.2%~0.5% of the dry basis of manure.

[0035] After the manure is flocculated and concentrated, it enters the mechanical sieve for preliminary separation and the screw extrusion dehydrator to separate again. After separation, the solid waste rate of the sewage is about 3%, and it enters the modular sewage treatment equipment for sewage treatment; after separation, the water content of the flocs is 80% %, containing a large number of Escherichia coli and other colonies, and the organic matter content is 15%~45%.

[0036] Second, modular sewage treatment; the modularization of sewage treatment equipment has the advantages of flexibility ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com