Rapidly started and stopped garbage conveying device

A garbage conveying and fast technology, applied in the direction of conveyors, transportation and packaging, packaging, etc., can solve the problems of high energy consumption of fuel engines, limited working capacity, slow start and stop speed, etc., to achieve simple and practical structure, prevent overload, fast action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

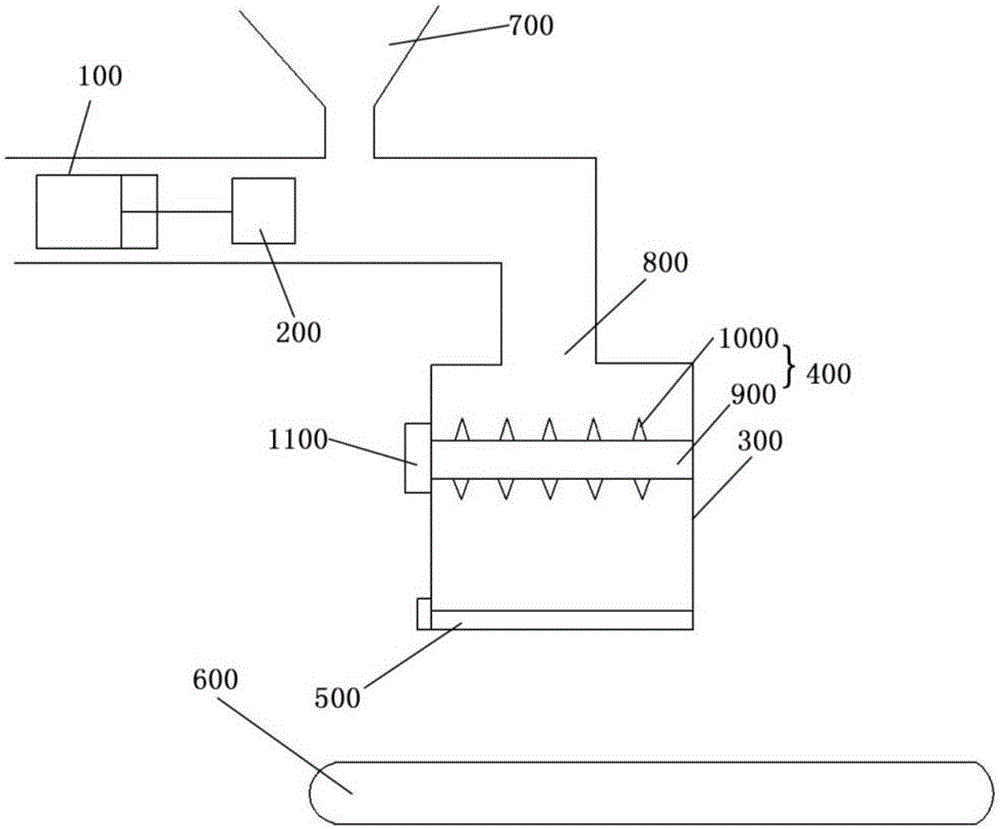

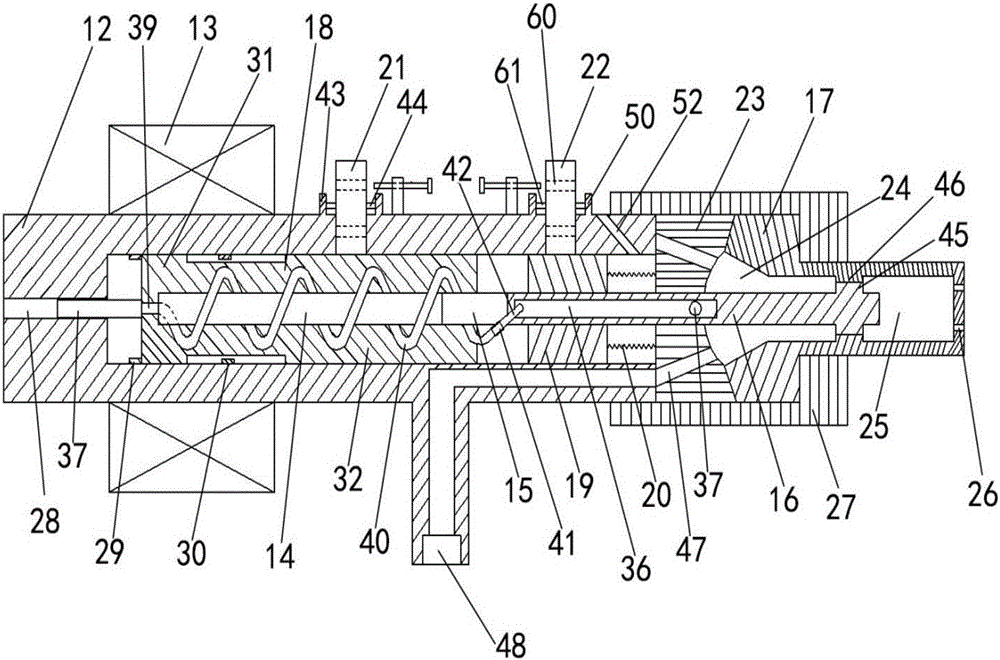

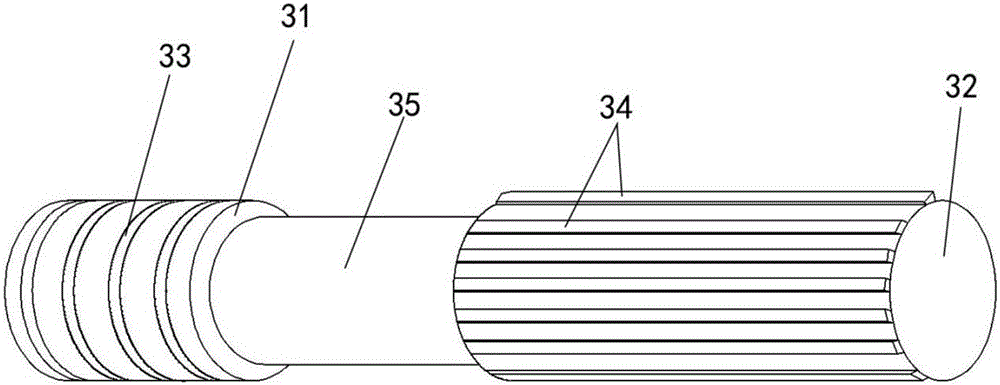

[0024] Such as figure 1 A garbage conveying device with fast start and stop shown includes a power cylinder 100, a pusher 200, a transfer box 300, a breaker 400, an electric discharge gate 500 and a conveyor belt 600; the pusher 200 and the power cylinder The pistons of 100 are connected, and the power cylinder 100 uses fuel injection to drive the piston to move so as to drive the pusher 200 to move; the garbage falls from the lower opening of the garbage bucket 700 and is pushed to the transfer port 800 by the pusher 200, and then falls into the The transfer box 300; the breaker 400 includes a rotating shaft 900 and an edge knife 1000 installed on the rotating shaft. The rotating shaft 900 driven by a motor 1100 is arranged horizontally. The garbage falling from the transfer port 800 is broken by the rotating edge knife 1000 during the falling process , and then fall into the transfer space at the lower part of the transfer box 300. The electric discharge door 500 is arranged a...

Embodiment 2

[0032] Such as figure 1 A garbage conveying device with fast start and stop shown includes a power cylinder 100, a pusher 200, a transfer box 300, a breaker 400, an electric discharge gate 500 and a conveyor belt 600; the pusher 200 and the power cylinder The pistons of 100 are connected, and the power cylinder 100 uses fuel injection to drive the piston to move so as to drive the pusher 200 to move; the garbage falls from the lower opening of the garbage bucket 700 and is pushed to the transfer port 800 by the pusher 200, and then falls into the The transfer box 300; the breaker 400 includes a rotating shaft 900 and an edge knife 1000 installed on the rotating shaft. The rotating shaft 900 driven by a motor 1100 is arranged horizontally. The garbage falling from the transfer port 800 is broken by the rotating edge knife 1000 during the falling process , and then fall into the transfer space at the lower part of the transfer box 300. The electric discharge door 500 is arranged...

Embodiment 3

[0040] Such as figure 1 A garbage conveying device with fast start and stop shown includes a power cylinder 100, a pusher 200, a transfer box 300, a breaker 400, an electric discharge gate 500 and a conveyor belt 600; the pusher 200 and the power cylinder The pistons of 100 are connected, and the power cylinder 100 uses fuel injection to drive the piston to move so as to drive the pusher 200 to move; the garbage falls from the lower opening of the garbage bucket 700 and is pushed to the transfer port 800 by the pusher 200, and then falls into the The transfer box 300; the breaker 400 includes a rotating shaft 900 and an edge knife 1000 installed on the rotating shaft. The rotating shaft 900 driven by a motor 1100 is arranged horizontally. The garbage falling from the transfer port 800 is broken by the rotating edge knife 1000 during the falling process , and then fall into the transfer space at the lower part of the transfer box 300. The electric discharge door 500 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com