Cutting head with positioning mechanism, cutting device and cutting method

A positioning mechanism and cutting device technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of difficult cutting and blanking, and achieve the effect of simple application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

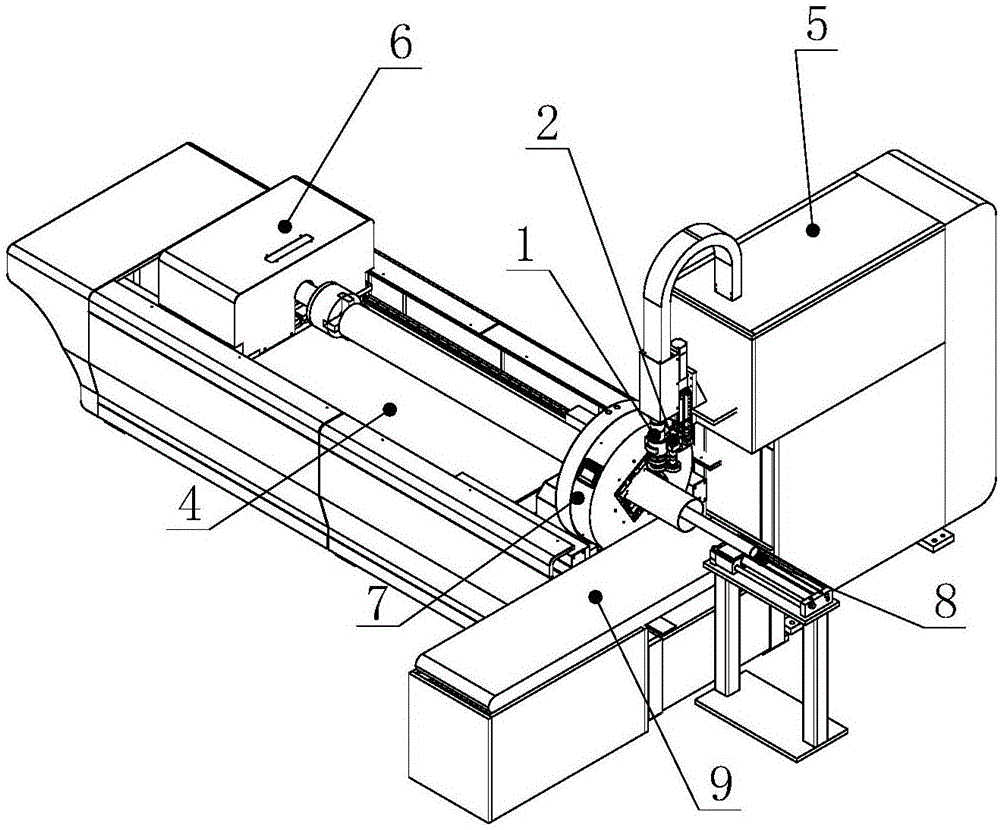

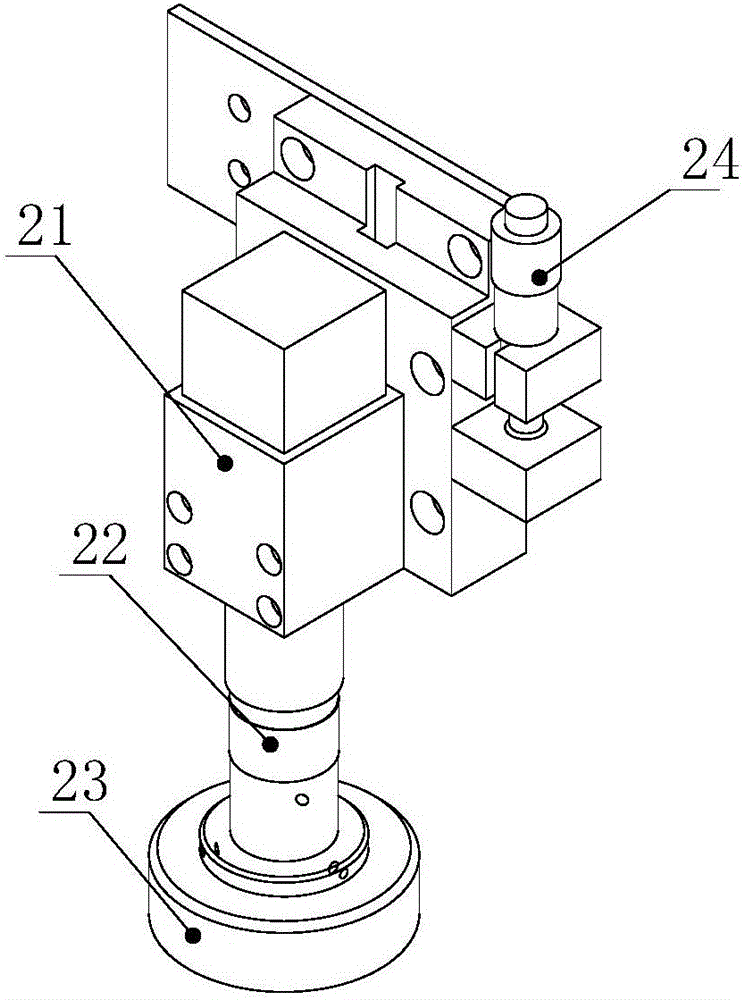

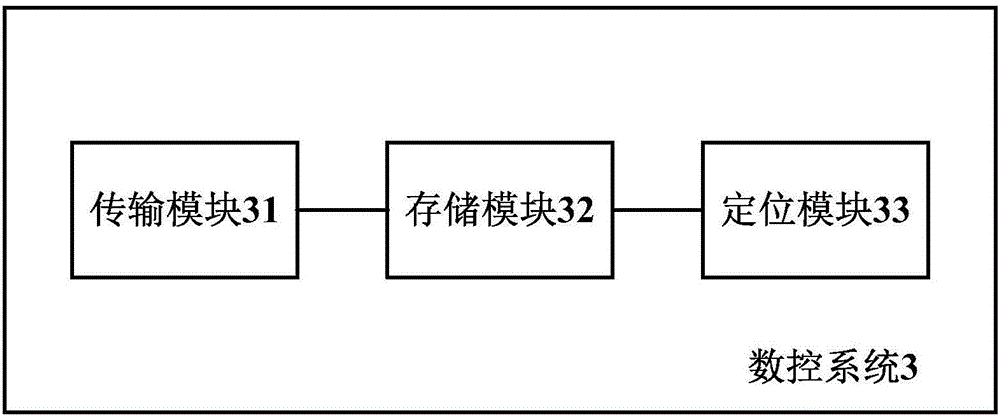

[0025] see figure 1 with figure 2 As shown, the embodiment of the present invention provides a cutting head with a positioning mechanism, the side of the cutting head 1 is provided with a visual imaging unit 2, and the visual imaging unit 2 includes a CCD camera 21 connected in sequence from top to bottom , a depth-of-field lens 22 and a ring light source 23, and the side of the CCD camera 21 is provided with a lifting regulator 24, which is used to adjust the lifting height of the depth-of-view lens 22.

[0026] Specifically, the CCD camera 21 is black and white with 130W pixels and a resolution of 1280*1024. In this embodiment, the 4.130-CCD camera uses a Gigabit Ethernet interface, and it is recommended to use a Gigabit network card or a switch with an intel chip. The overall dimensions are 50mm*38mm*38mm. The CCD adopts a standard C-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deformity rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com