Electric welding machine circuit powered by lithium batteries

A technology of electric welding machine and lithium battery, which is applied in the direction of arc welding equipment, welding equipment, DC power supply parallel operation, etc. It can solve the problems of reducing production efficiency and wasting time, and achieves the improvement of work efficiency, high efficiency, and good current controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described now in conjunction with accompanying drawing.

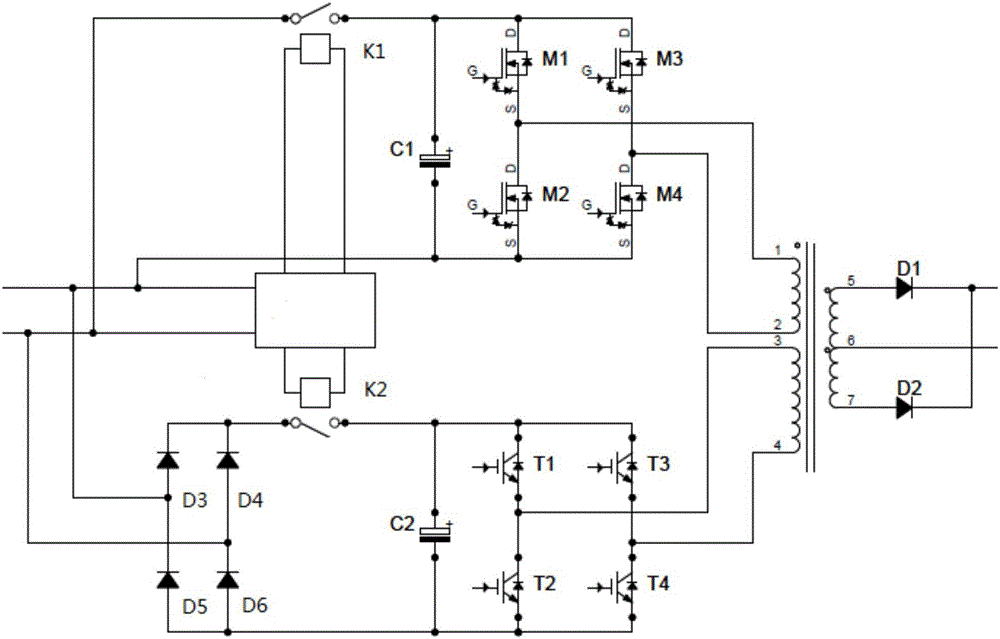

[0018] see figure 1 , The present invention is an electric welding machine circuit powered by a lithium battery, including an intelligent voltage determination circuit, a metal-oxide semiconductor field effect transistor, an insulated gate bipolar transistor, a relay, an electrolytic capacitor, a transformer and an output rectification circuit.

[0019] The input end of the intelligent voltage judging circuit is connected to the input power supply, and the control signal output end of the intelligent voltage judging circuit is divided into two circuits and respectively connected to the two ends of the coil of relay one K1 and the two ends of the coil of relay two K2.

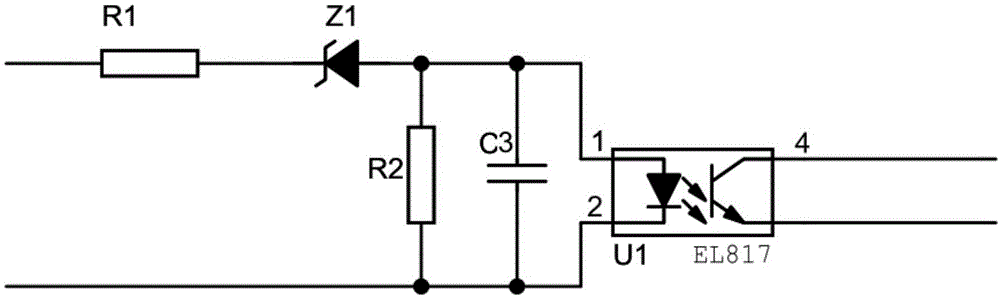

[0020] see figure 2 , the intelligent voltage determination circuit includes a resistor R1, a resistor R2, a Zener diode Z1, a capacitor C3, a photocoupler U1, one end of the resistor R1 is connected to one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com