Production line of resistance silencing tube for vehicle

A sound-absorbing pipe and production line technology, which is applied in metal processing equipment, perforating tools, safety equipment, etc., can solve problems such as incomplete punching, weakened impact force of punches, and low product quality, so as to achieve natural and smooth pressure relief and avoid damage. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

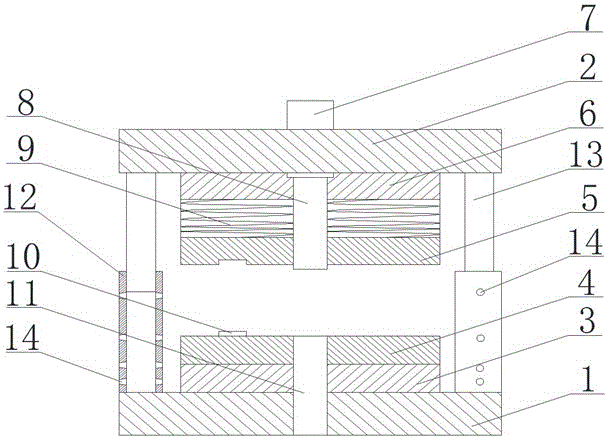

[0028] like figure 1 As shown, the present invention is a production line for a vehicle resistant muffler pipe, comprising a lower mold base 1, an upper mold base 2, a film handle 7 is fixed on the top of the upper mold base 2, and a punch fixing plate 6, And the guide rod 13 perpendicular to the upper die base 2, the bottom of the punch holder 6 is vertically provided with a punch 8, the upper end of the punch 8 runs through the punch holder 6, and is fixed on the bottom of the upper die holder 2, and the lower die holder 1 is fixed with a discharge plate 4 and a guide cylinder 12 matching with the guide rod 13. The discharge plate 4 is provided with a punching hole 11 matching the punch 8, and the punching hole 11 runs through the discharge plate 4 and the lower Die base 1, guide cylinder 12 sidewalls are provided with some through holes 14 parallel to the horizontal plane, through holes 14 communicate with the interior and exterior space of guide cylinder 12, and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com