Cleaning vehicle for contact network insulators

A technology for insulators and cleaning vehicles, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of poor water resources and cleaning effects, large consumption, etc., achieve ingenious structural design and save manpower The effect of high cost and cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

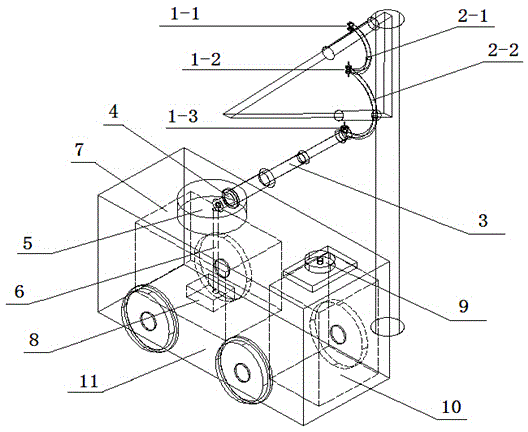

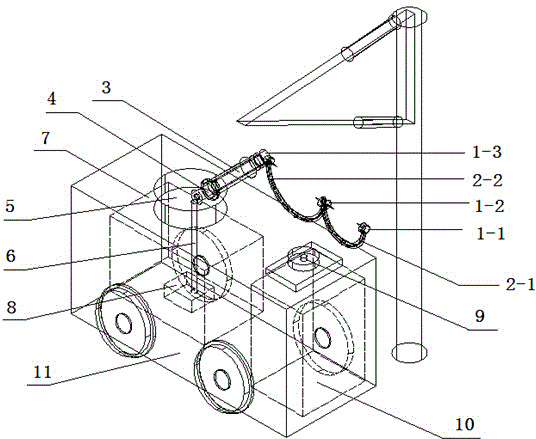

[0019] Such as figure 1 As shown, the catenary insulator cleaning vehicle includes top high-pressure nozzle 1-1, middle high-pressure nozzle 1-2, bottom high-pressure nozzle 1-3, upper semicircular arm 2-1, and lower semicircular arm 2 -2, insulated rotating telescopic arm 3, hydraulic motor 4, rotating platform 5, cleaning liquid delivery pipe 6, cleaning liquid storage tank 7, high-pressure water pump 8, distance measuring sensor 9, controller 10, and vehicle body 11.

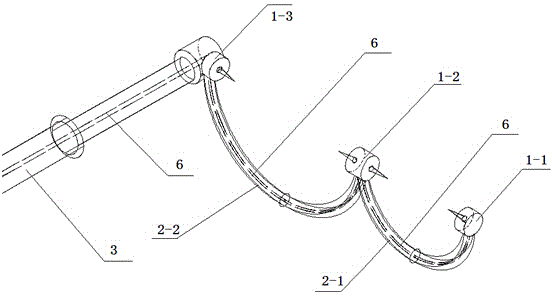

[0020] Such as figure 1 and 2 As shown, the top high-pressure nozzle 1-1 is installed on the top of the upper semicircular arm 2-1, and the bottom of the upper semicircular arm 2-1 is connected to the top of the lower semicircular arm 2-2. A middle-end high-pressure nozzle 1-2 is installed at the connection between the bottom of the circular arm 2-1 and the top of the lower semicircular arm 2-2, and the bottom of the lower semicircular arm 2-2 is connected to one end of the insulating rotating telescopic ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com