An m16 bolt action structure for a shotgun

A technology of M16 and bolt action, which is applied in the field of M16 bolt action structure for shotguns, can solve the problems of large shell deformation, reduced containment area, and reduced barrel strength, etc., to achieve small deformation of the shell case, reduced weakening, and large containment area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The working principle and structure of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

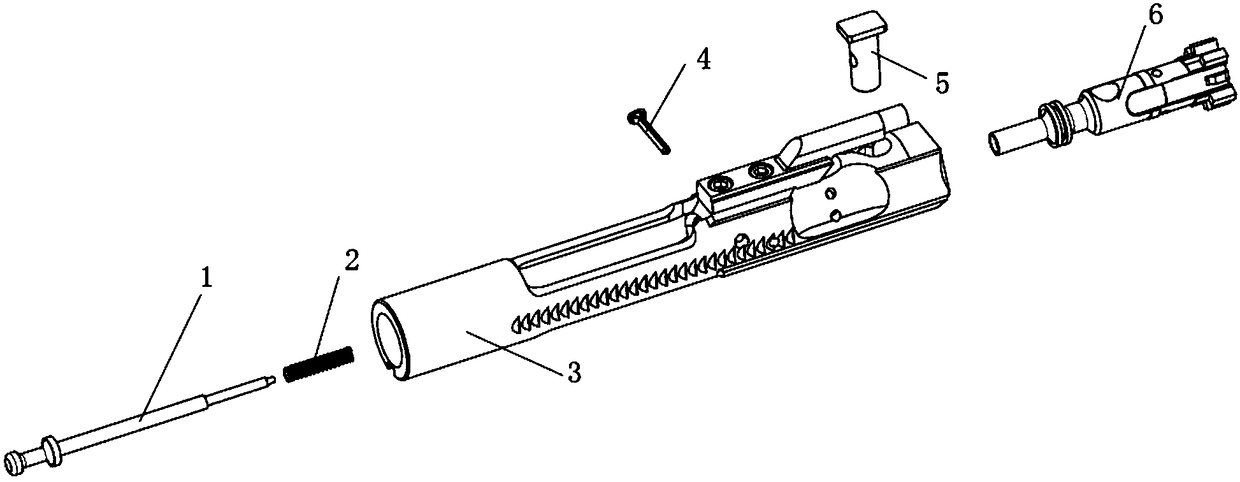

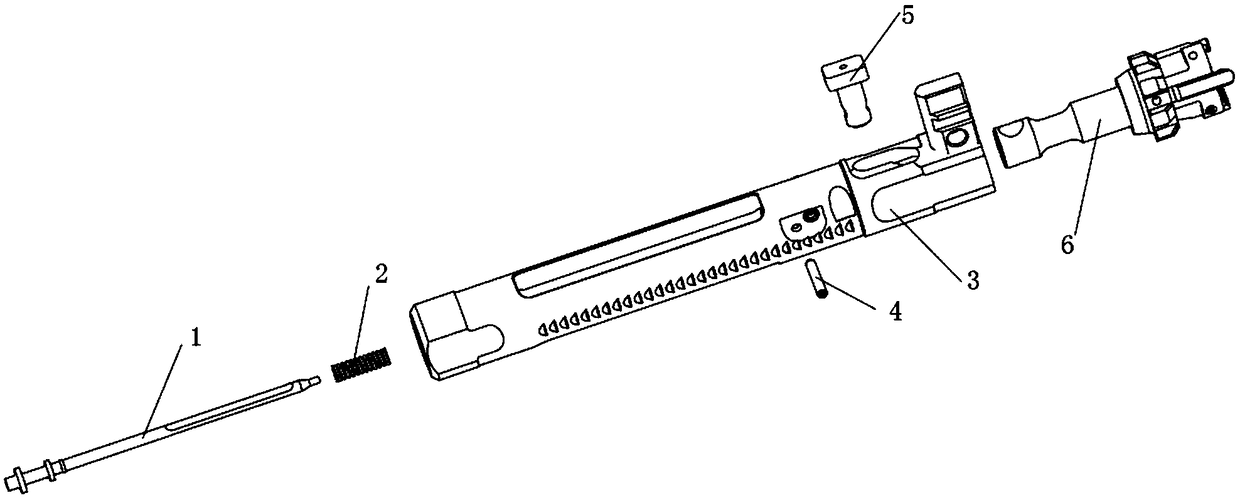

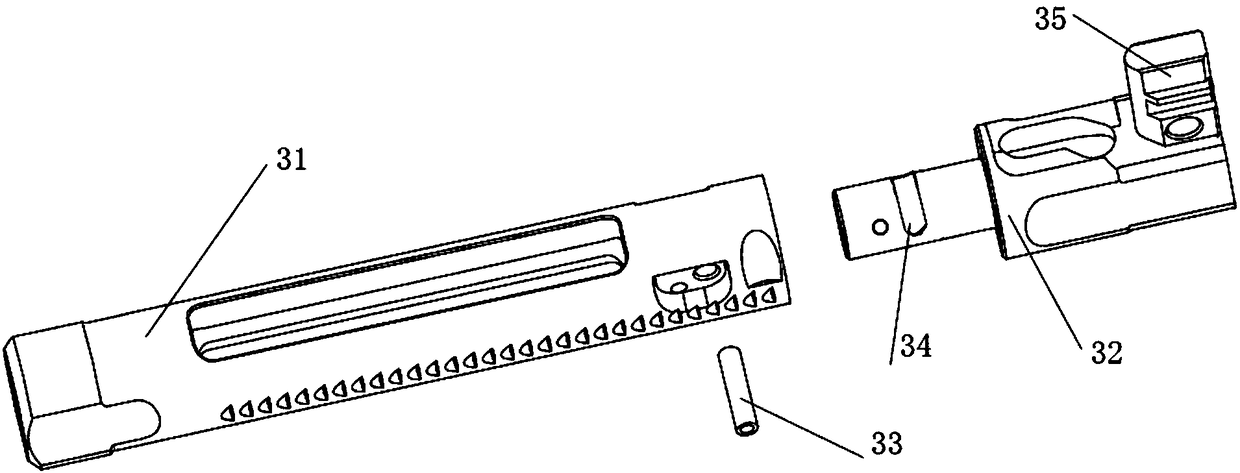

[0027] Such as figure 2 , Figure 5 As shown, an M16 bolt action structure for a shotgun includes a firing pin 1, a firing pin spring 2 sleeved on the firing pin, a machine frame assembly 3, a firing pin pin 4 connecting the firing pin and the machine frame assembly, and a guide post 5 and the machine head assembly 6, the guide post 5 is provided with a through hole for the firing pin 1 to pass through, the machine frame assembly 3 includes a guide tube 31 and a machine frame 32, and the machine frame 32 is placed on the guide tube 31 The front end is connected as a whole by the connecting pin 33 of the machine frame. The top of the machine frame 32 is provided with a spiral groove along the axial direction, and the guide post 5 is placed in the spiral groove. The inside of the machine frame 32 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com