Fresh keeping agent for prolonging carnation cut flower vase life and preparation method thereof

The technology of carnation and antistaling agent is applied in the field of antistaling agent for improving the life of carnation cut flower vase and its preparation, which can solve the problems of limitation, singleness, market production and application of research results, etc., and achieve the effect of prolonging the life of vase and delaying aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

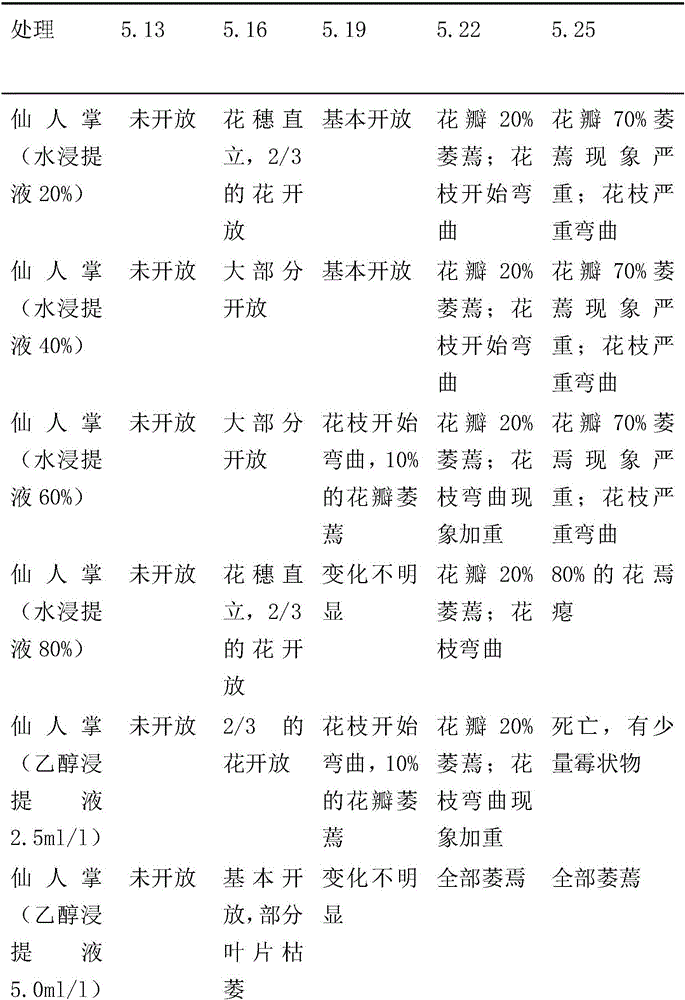

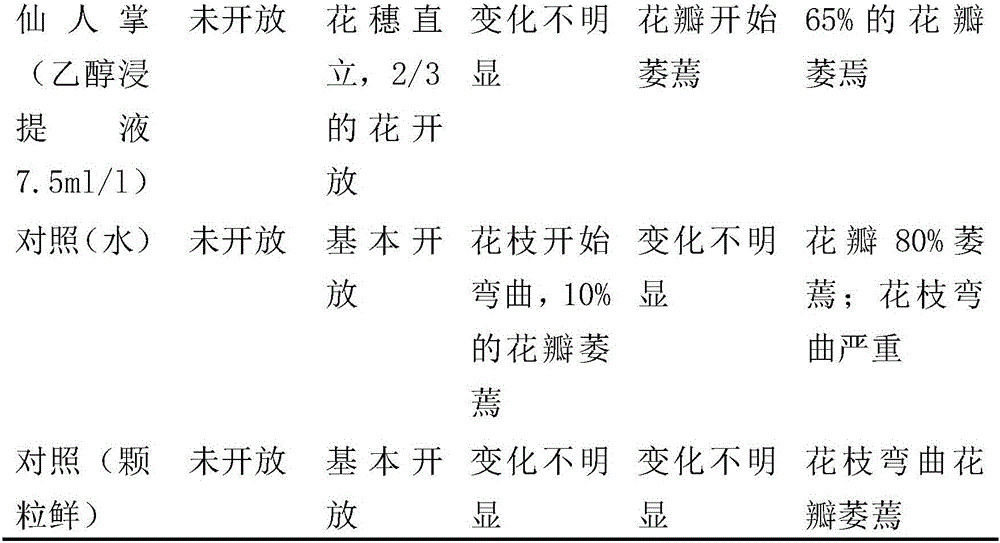

Examples

Embodiment 1

[0056] A preparation method of a preservative for improving the longevity of cut carnation vases, comprising the following steps: drying the cactus in the shade, adjusting the drying oven to 35-40°C, drying for 12 hours, pulverizing the material with a powder machine, and passing through 20 meshes Sieve, pack into bags separately, store at 4°C for later use; weigh 50g of the crushed cactus plant sample, add quantitative 95% ethanol, the standard is to soak the sample by more than 4cm according to the sample volume, soak, put it in a shaker and shake for 48h. Suction filtration under reduced pressure to obtain the filtrate and residue; add an appropriate amount of 95% ethanol to the residue extracted for the first time, just immerse the sample for 1 cm, soak it, and shake it in a shaker for 24 hours. Suction filtration under reduced pressure to obtain the filtrate and residue; add an appropriate amount of 95% ethanol to the above residue, just submerge the sample, soak, and shak...

Embodiment 2

[0058] A preparation method of a preservative for improving the longevity of carnation cut vases, comprising the following steps: drying the cactus in the shade, adjusting the drying oven to 35°C, drying for 16 hours, pulverizing the material with a powder machine, passing through a 15-mesh sieve, Bag them separately and store them at 4°C for later use; take the crushed cactus plant samples and add a quantitative amount of ethanol with a volume percentage of 95%. The standard is to soak the samples by more than 4cm according to the sample volume, soak them, and shake them in a shaker for 51 hours; Suction filtration under reduced pressure to obtain filtrate and residue; add ethanol with a volume percentage of 95% to the residue that was lifted for the first time, just immerse the sample for 1 cm, soak, put into a shaker and shake for 20 hours; suction filtration under reduced pressure to obtain Filtrate and residue; add 95% ethanol to the above residue, just immerse the sample,...

Embodiment 3

[0060] A preparation method of a preservative for improving the lifespan of carnation cut vases, comprising the following steps: drying the cactus in the shade, adjusting the drying oven to 40°C, drying for 8 hours, pulverizing the material with a powder machine, passing through a 25-mesh sieve, Bag them separately and store them at 4°C for later use; take the crushed cactus plant samples and add a quantitative amount of ethanol with a volume percentage of 95%. The standard is to soak the samples by more than 4cm according to the sample volume, soak them, and shake them in a shaker for 45 hours; Suction filtration under reduced pressure to obtain the filtrate and residue; add ethanol with a volume percentage of 95% to the residue that was lifted for the first time, just immerse the sample for 1 cm, soak, put it into a shaking table and shake for 28 hours; filter under reduced pressure to obtain Filtrate and residue; add 95% ethanol to the above residue, just immerse the sample,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com