Laminated battery structure, secondary battery pack comprising same and battery pack module

A laminated, battery pack technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of unguaranteed battery safety, poor battery cycle performance, a lot of time and energy, etc., to improve production and preparation. Efficiency, the effect of improving production and preparation efficiency, and reducing production and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

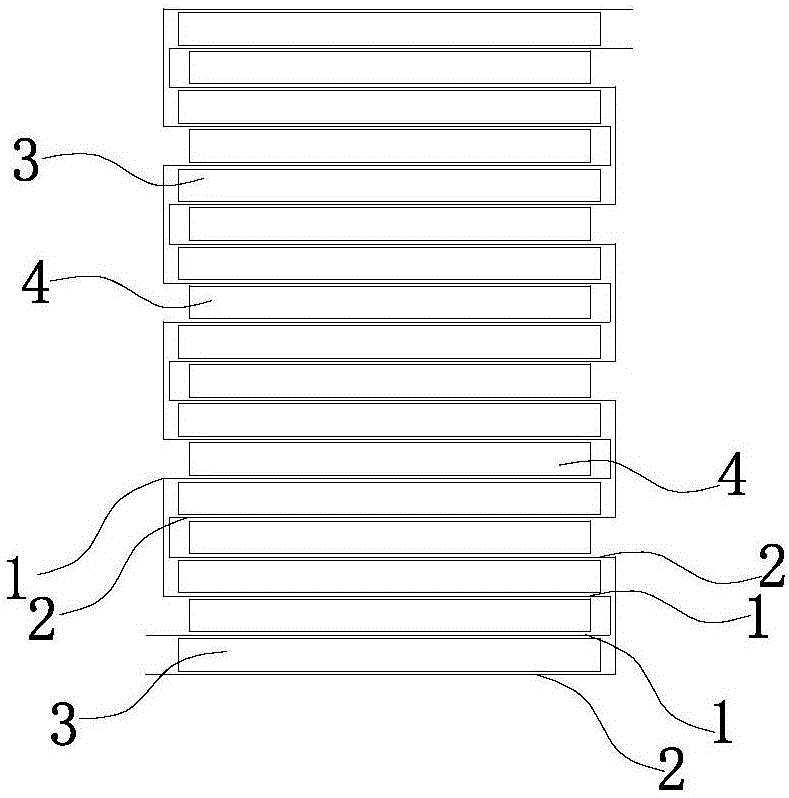

[0028] refer to figure 1 , figure 1 It is the structural diagram of the stacked battery in Example 1. The present invention provides a stacked battery structure, including a battery cell, and the battery cell includes two layers of continuous separators 1, 2 oppositely arranged, and the two layers are continuous A plurality of first battery cells 3 arranged at intervals are sandwiched between the continuous separators 1, 2, and the two layers of continuous separators 1, 2 and the first battery cells 3 sandwiched between them are folded in a zigzag to form a stack. A sheet battery cell, the second battery unit 4 is sandwiched between the outer sides of the two continuous separators 1 and 2, and the two pole pieces of the second battery unit 4 and the first battery unit 3 are close to each other to form an electrode pair. In this embodiment, the first battery unit 3 is a negative unipolar sheet, the second battery unit 4 is a positive unipolar sheet, and the outermost electrod...

Embodiment 2

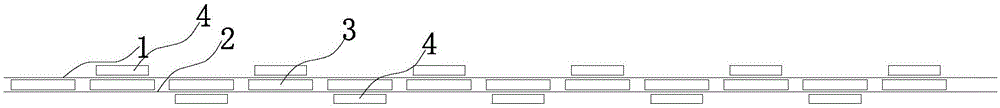

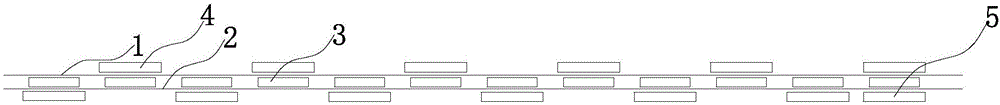

[0032] refer to Figure 3-4 , image 3 It is the structure diagram before the battery structure of Example 2 is folded, Figure 4 It is the structural diagram of the laminated battery of Embodiment 2. This embodiment is basically the same as Embodiment 1, the difference is that: the first battery unit 3 is a positive monopolar sheet, and the second battery unit 4 is a negative monopolar sheet. pole piece. After folding, the outermost pole piece of the laminated battery structure is a negative pole piece, that is, a negative pole piece is arranged below the first and last first battery unit 3 or the outer pole piece is a negative pole structure , in this embodiment, a negative electrode sheet 5 is arranged below the first and the last first battery unit 3 respectively.

Embodiment 3

[0034] refer to Figure 5 , Figure 5 It is the structural diagram of the battery structure of Example 3 before folding. This embodiment is basically the same as that of Example 1, except that the first battery unit 3 is a positive electrode / diaphragm / negative electrode structure, and the even-numbered cells from the second one are The second battery unit 4 corresponding to the first battery unit 3 is arranged on the upper continuous separator 1, and the second battery unit 4 corresponding to the odd-numbered first battery unit 3 from the third is arranged on the Below the continuous diaphragm 2 of the lower layer, the second battery unit 4 arranged on the continuous diaphragm 1 of the upper layer is a structure in which the negative electrode single pole piece or the outer pole pieces are all negative electrodes, and the continuous diaphragm 1 of the lower layer is arranged The second battery unit 4 below is a structure in which the positive pole piece or the outer pole piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com