Powder off prevention battery grid suitable for rolling brush process

A grid and process technology, which is applied in the field of anti-powder battery grid, can solve the problems of shortened service life, low density, and inability to remove active substances by rolling brushes, etc., so as to protect the service life and improve the safety of use sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

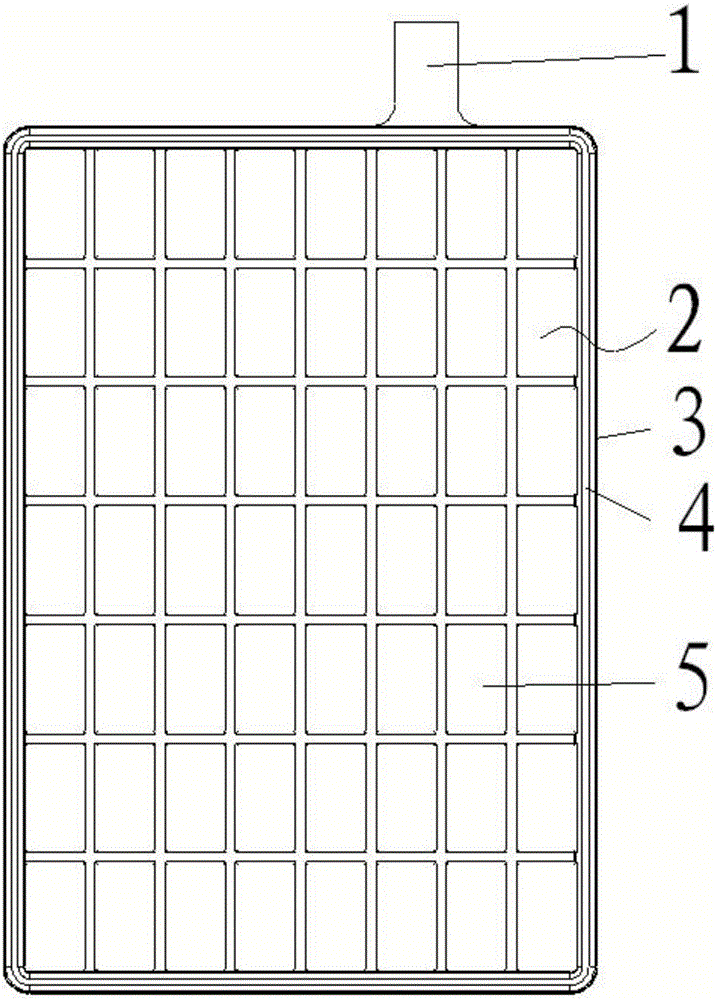

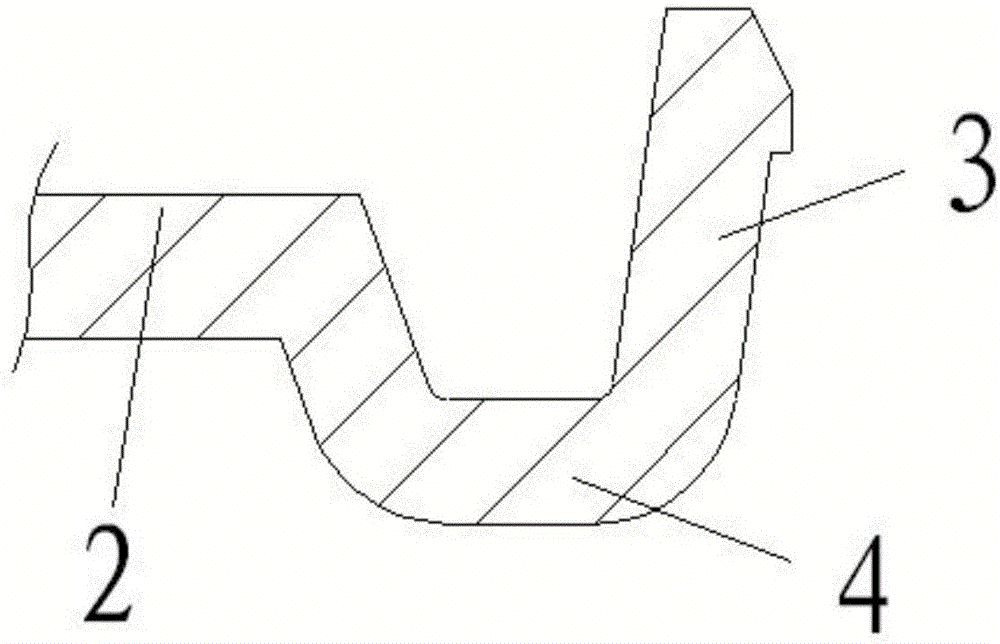

[0013] Such as Figures 1 to 3 As shown in one, the present invention includes a tab 1 and a grid body 2, the grid body 2 is coated with an active material, and the grid body 2 is provided with a grid plane 5 with a grid, The surrounding edge of the grid plane 5 is provided with a bending edge 3 , and the junction of the bending edge 3 and the grid plane 5 forms a bend 4 .

[0014] After the battery grid is stamped and formed, it is necessary to coat the surface with an active material. Preferably, the active material is lead paste. After the lead paste is coated on the grid body 2, the periphery of the grid body 2 needs to be Since the edge of the grid body 2 is provided with a bending edge 3, the lead plaster on the side of the bending edge 3 is cleaned when cleaning with a roller brush, and some of the lead plaster on the grid body is cleaned. 2 The lead paste on the edge is brushed into the bend 4 when cleaning, and the lead paste that is partly cleaned is stored in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com