Optical reflection film with low thermal shrinkage rate, and preparation method therefor

A technology of optical reflection and shrinkage rate, which is applied in the field of polyester film, can solve the problems of incomplete cooling, incomplete release of internal stress, large thermal shrinkage, etc., and achieve excellent flatness, complete release of internal stress, and sufficient shaping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

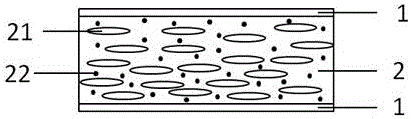

[0026] An optical reflective film with low heat shrinkage rate, comprising a main layer of the reflective film and an auxiliary layer, the main layer is composed of the following materials in parts by weight: 2 parts of TiO with a particle size of 0.3 μm 2 , 2 parts of nucleating agent, 10 parts of polypropylene resin, 86 parts of polyethylene terephthalate, wherein the PET resin has a pore structure;

[0027] The auxiliary layer is made up of the following parts by weight: 85 parts of polyethylene terephthalate, 10 parts of antiblocking agent, 5 parts of antistatic agent, containing 0.3% SiO2 in the antiblocking agent 2 .

[0028] The preparation method of the optical reflective film with low heat shrinkage rate is as follows: according to the above formula, the raw materials used for the main layer and the auxiliary layer are respectively weighed, and after being dried and mixed by a mixing device, they are respectively melted and mixed by a twin-screw extruder, The main la...

Embodiment 2

[0031] An optical reflective film with low heat shrinkage rate, comprising a main layer of the reflective film and an auxiliary layer, the main layer is composed of the following parts by weight: 5 parts of TiO with an average particle size of 0.1 μm 2 , 3 parts of nucleating agent, 12 parts of polypropylene resin, 80 parts of polystyrene, wherein the PET resin has a pore structure;

[0032] The auxiliary layer is made up of the following parts by weight: 85 parts of polyethylene terephthalate, 10 parts of antiblocking agent, 5 parts of antistatic agent, containing 0.3% SiO2 in the antiblocking agent 2 .

[0033] The preparation method of the optical reflective film with low heat shrinkage rate is as follows: according to the above formula, the raw materials used for the main layer and the auxiliary layer are respectively weighed, and after being dried and mixed by a mixing device, they are respectively melted and mixed by a twin-screw extruder, The main layer and the auxilia...

Embodiment 3

[0036] An optical reflective film with low heat shrinkage rate, comprising a main layer of the reflective film and an auxiliary layer, the main layer is composed of the following parts by weight: 5 parts of barium sulfate with an average particle size of 0.8 μm, 5 parts of nucleating agent, 15 parts Parts of polypropylene resin, 75 parts of polyethylene terephthalate, wherein the PET resin has a pore structure;

[0037] The auxiliary layer is made up of the following parts by weight: 75 parts of polyethylene terephthalate, 20 parts of antiblocking agent, 5 parts of antistatic agent, containing 0.5% SiO2 in the antiblocking agent 2 .

[0038] The preparation method of the optical reflective film of described low heat shrinkage rate is the same as embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com