A Simultaneous Dynamic Measurement Method of Refractive Index and Shape

A technology of dynamic measurement and refractive index distribution, applied in measurement devices, phase influence characteristic measurement, instruments, etc., can solve problems such as inability to use liquid object measurement and reduction in measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

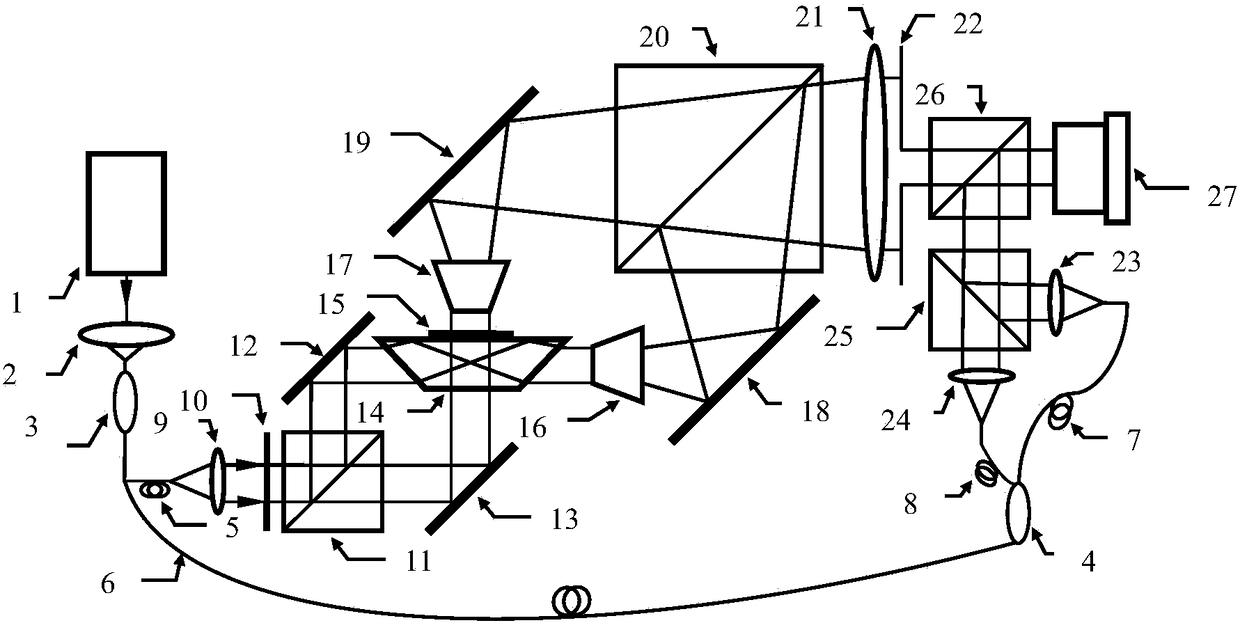

[0027] The present invention relates to an optical path system for simultaneous dynamic measurement of two-dimensional refractive index distribution and three-dimensional shape, such as figure 1 As shown, it includes: semiconductor laser diode pumped solid-state laser 1, fiber coupler 2, first fiber splitter 3, second fiber splitter 4, first optical fiber 5, second optical fiber 6, third optical fiber 7, The fourth optical fiber 8, the first collimating lens 9, the half-wave plate 10, the first polarization beam splitter prism 11, the first reflector 12, the second reflector 13, the Dove prism 14, the sample 15, the first microscope objective lens 16 , the second microscope objective lens 17, the third mirror 18, the fourth mirror 19, the first dichroic prism 20, the imaging lens 21, the aperture stop 22, the second collimating lens 23, the third collimating lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com