Double-rotational-flow flat flame burner

A flat-flame burner and double-swirl technology, which is applied in the direction of burning with various fuels, combustion methods, and types of combustion, can solve the problems that the flat-flame burner is difficult to form a flat-flame production demand, and the actual capacity of the burner fluctuates. , to achieve single and comprehensive performance improvement, high applicability and reliability, and good flame stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

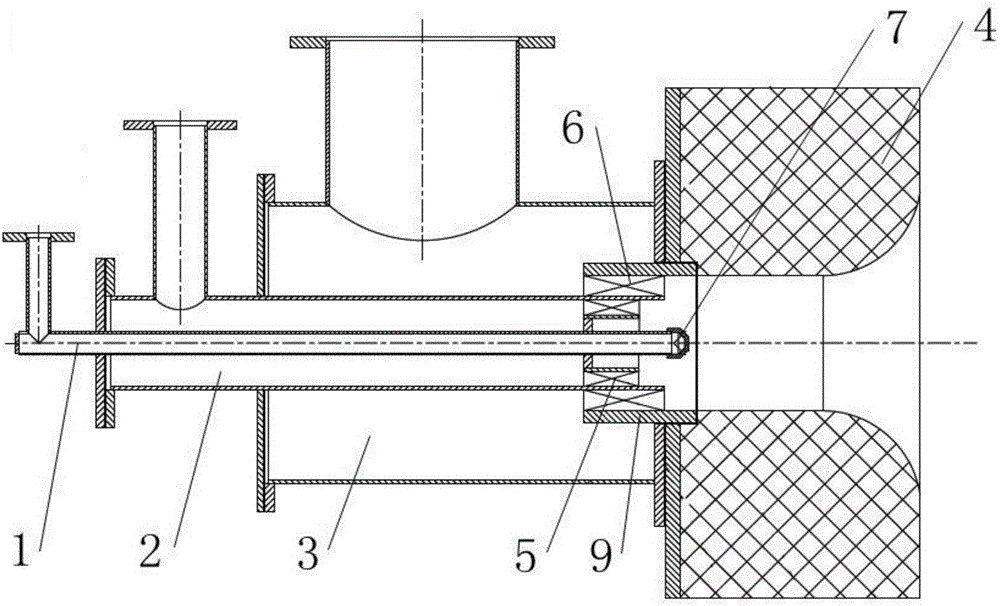

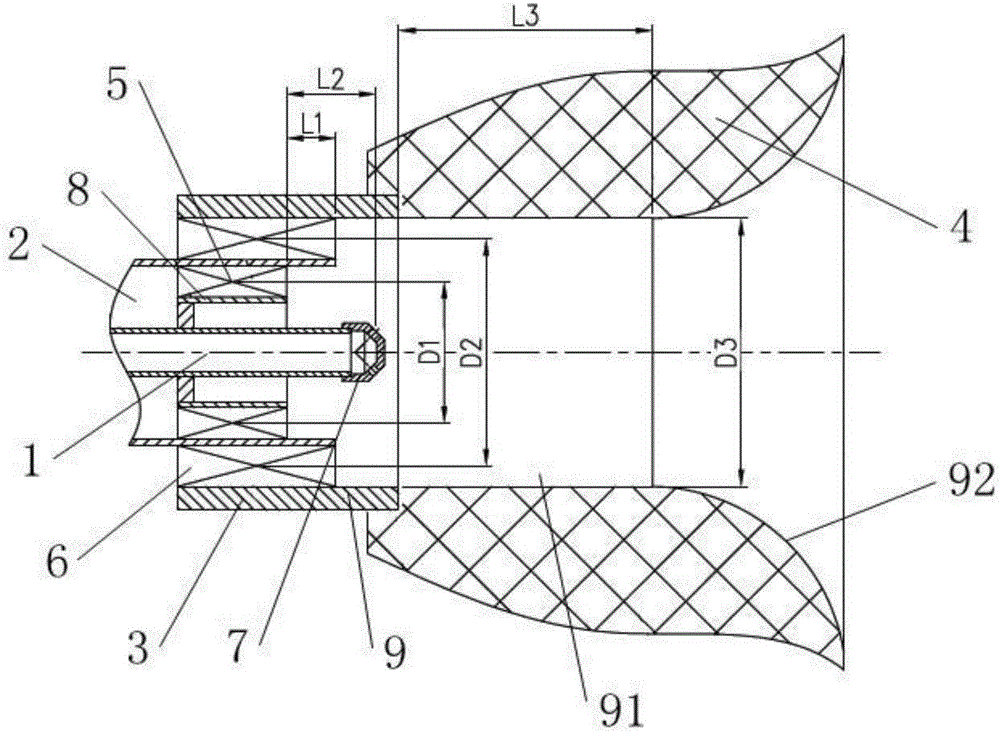

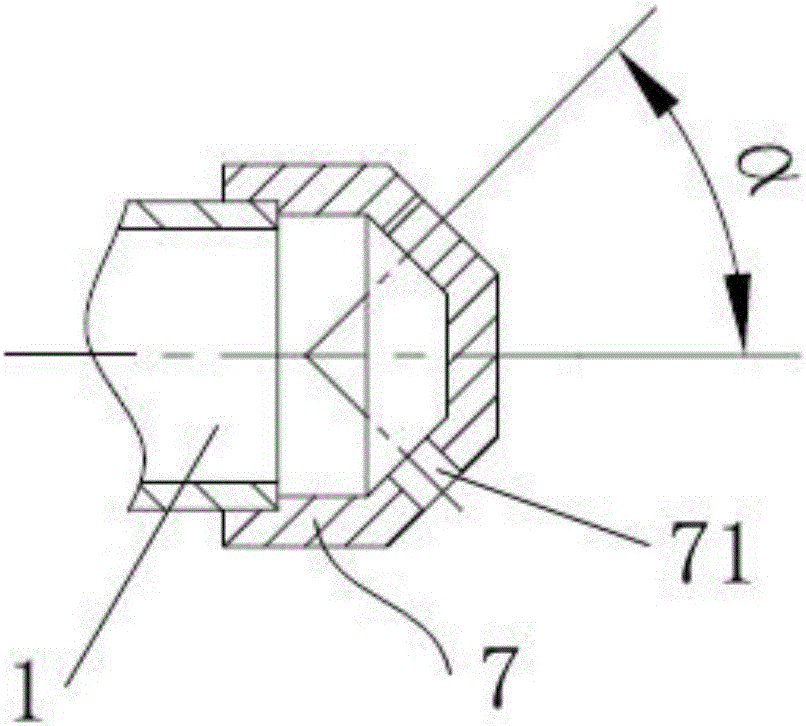

[0021] As shown in the figure, the double-swirl flat-flame burner in the present invention includes a central air pipe 1, a gas pipe 2, a main air pipe 3 and a burner body 4. The burner body 4 is provided with a combustion channel, so The central air pipe 1, the gas pipe 2 and the main air pipe 3 are coaxially arranged in sequence from the inside to the outside, the burner body 4 is arranged at the air outlet of the main air pipe 3 and the combustion channel is the same as the air outlet of the main air pipe 3. The shaft is connected; the gas pipe 2 and the main air pipe 3 are located at the air outlet and are correspondingly provided with a gas cyclone 5 and a main air cyclone 6, and the gas cyclone 5 is arranged between the central air pipe 1 and the gas pipe 2, the main air cyclone 6 is arranged between the gas pipe 2 and the main air pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com