Device and method for controlling diesel exhaust particulate pollutants

A technology of tail gas particles and control devices, which is applied in the direction of exhaust devices, noise reduction devices, mechanical equipment, etc., can solve the problem of consuming extra cost of urea, and achieve the effect of avoiding the loss of sound energy, enhancing the effect, and thoroughly removing particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

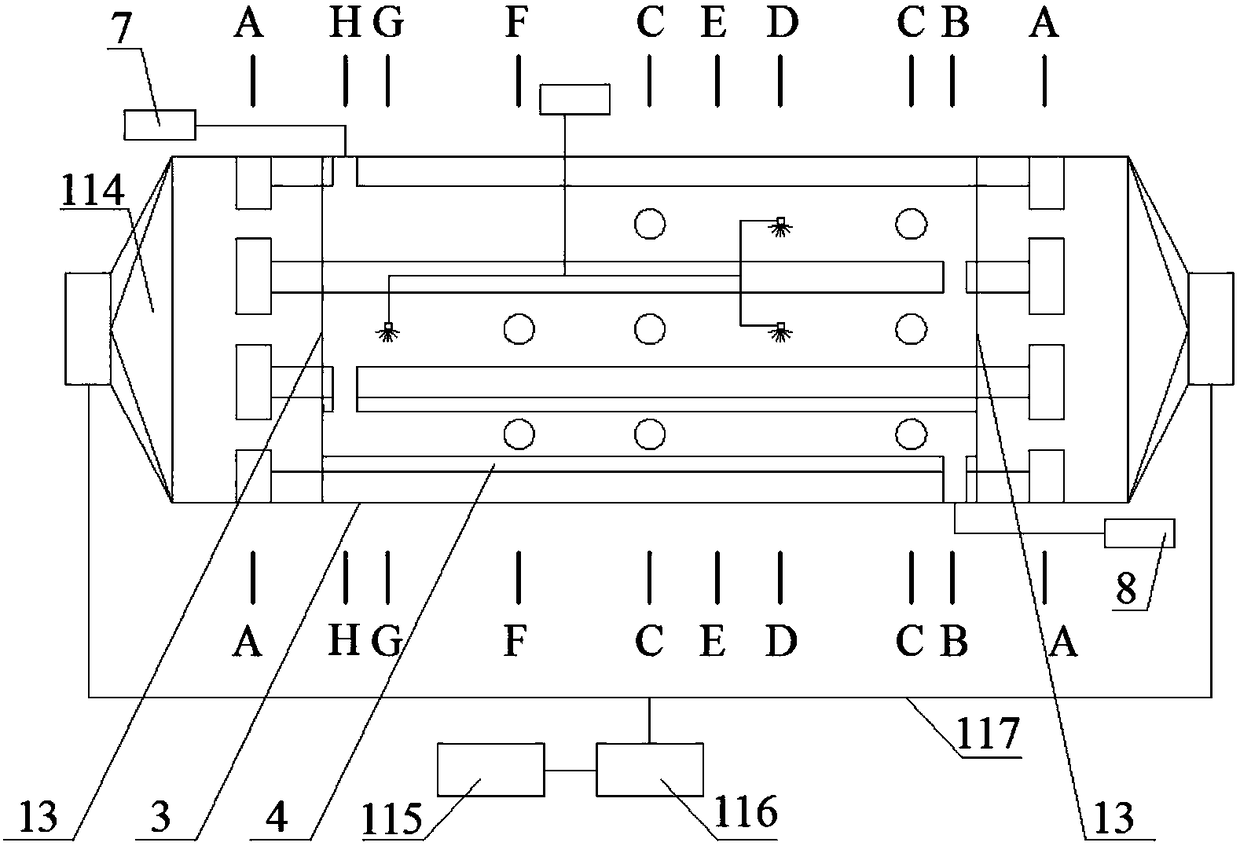

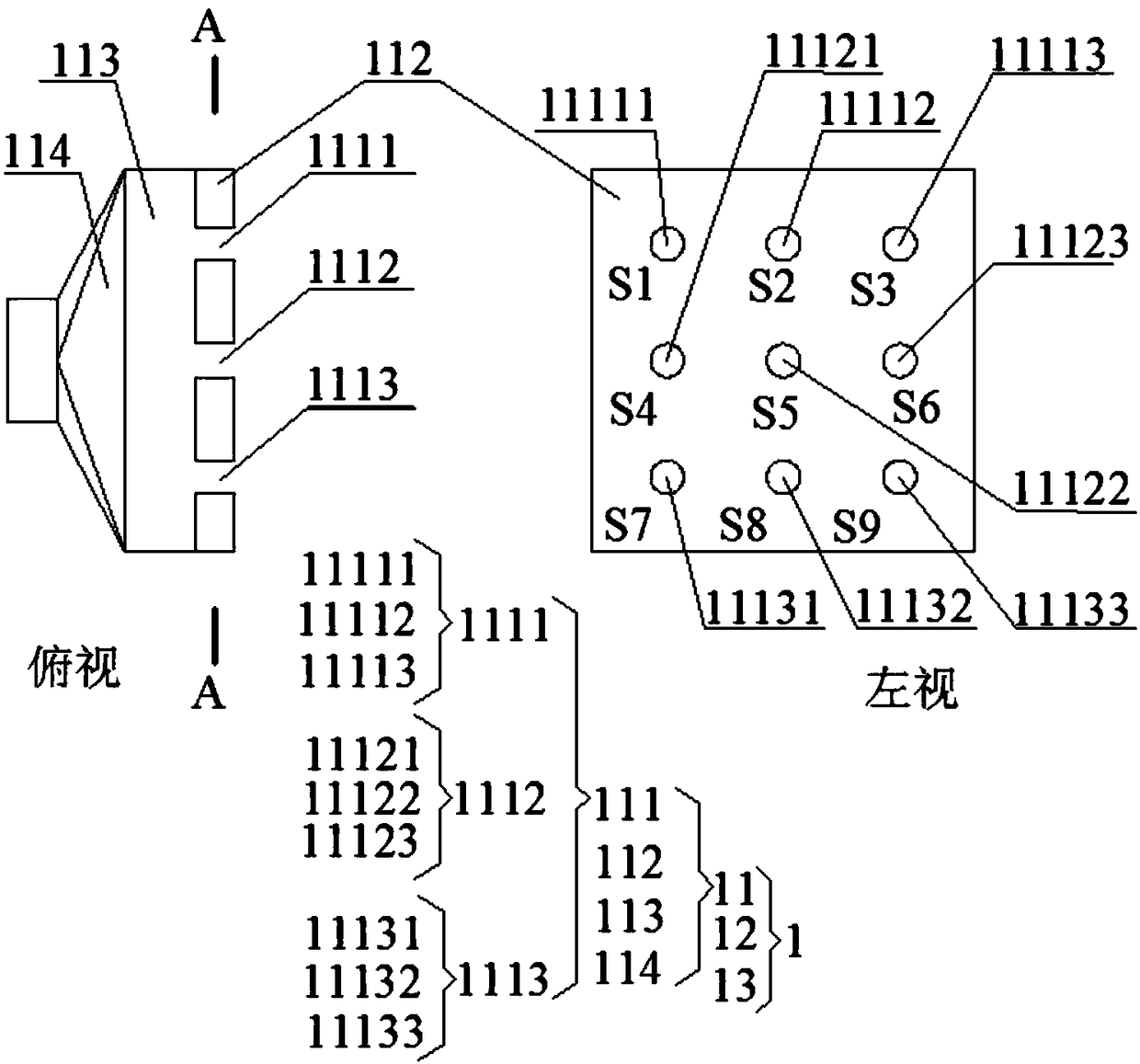

[0073] The working principle and process of the above-mentioned diesel engine exhaust particulate pollution control device are:

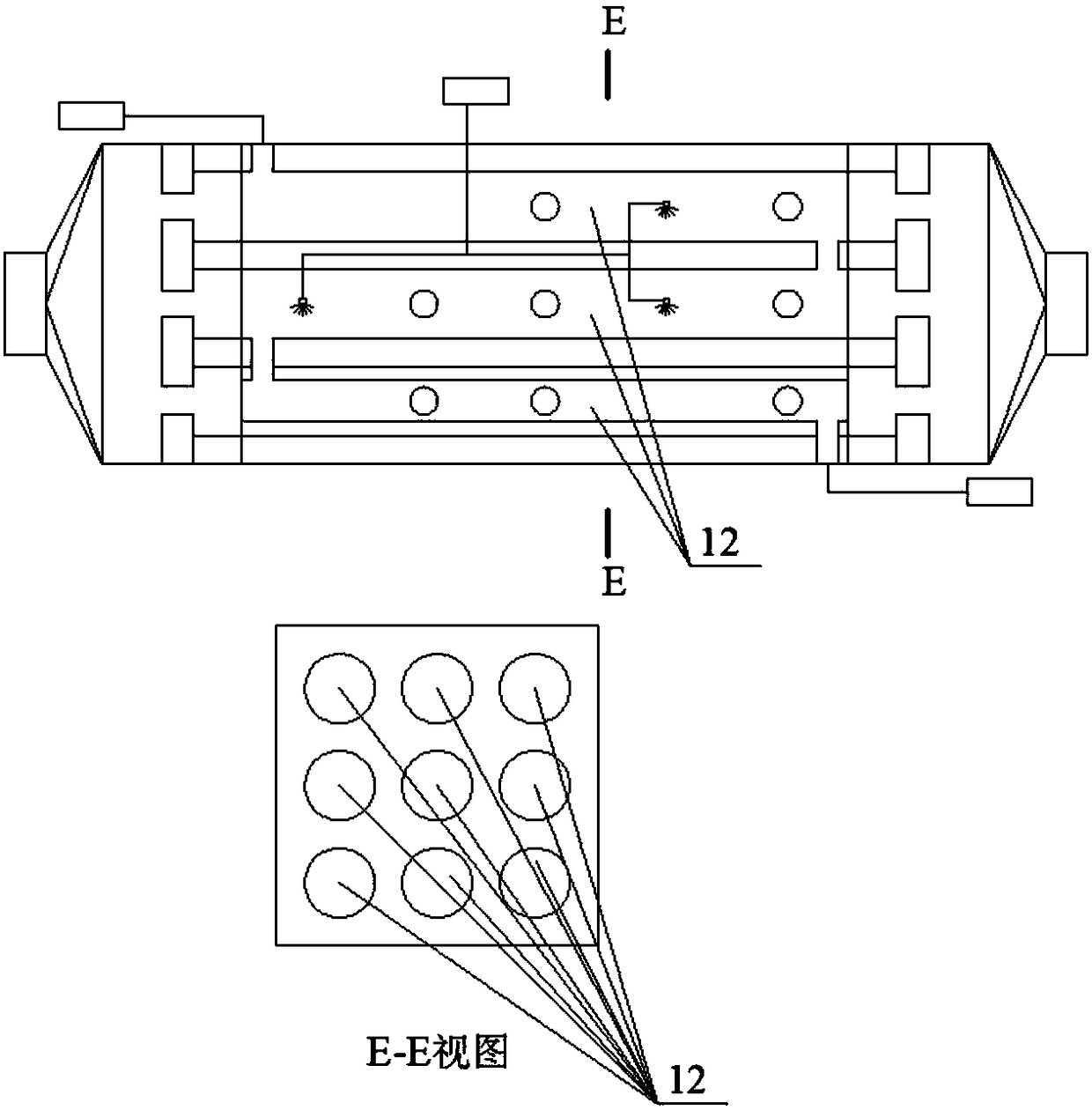

[0074] After the signal source generates a specific frequency signal, the speaker is driven by the power amplifier, which excites the air in the Helmholtz sound source to vibrate violently, and radiates sound waves synchronously from both ends of the array tube to each single tube through the through hole, and constructs a standing wave in the array tube The sound field forms a non-linear sound field.

[0075] After the exhaust gas of diesel engine is introduced into the array pipe, the suspended particles in the exhaust gas will move to the antinode / node of the standing wave sound field under the action of the nonlinear sound field, realizing the effect of directional movement of the suspended particles in space. Due to the accumulation of suspended particles at antinodes / nodes, a particle accumulation area with a large particle number concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com