Method for preventing DD99 alloy single crystal blade from generating initial melting defect

A single crystal blade, DD99 technology, which is applied in the fields of investment precision casting and single crystal blade vacuum heat treatment, can solve the problems that have not been seen to solve the initial melting defect of DD99 alloy single crystal turbine blade, so as to avoid the initial melting defect and improve the initial melting defect. The effect of melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

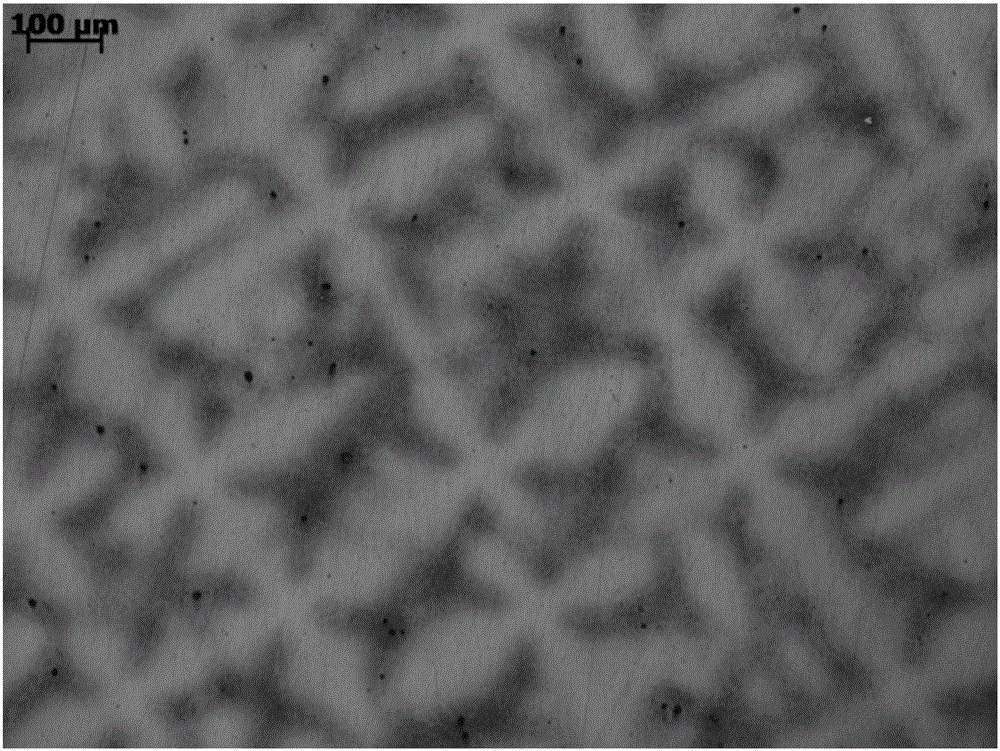

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] This embodiment is a method for preventing incipient melting defects from occurring in the working blade of a DD99 alloy single crystal high-pressure secondary turbine of an engine during vacuum solid solution treatment. The DD99 alloy single crystal high-pressure two-stage turbine working blade is a key part of an engine and a life-span part of the engine. The blade is a solid blade with a crown, the blade is slender, the chord width is relatively large, and the thickness of the exhaust edge is only 0.51mm.

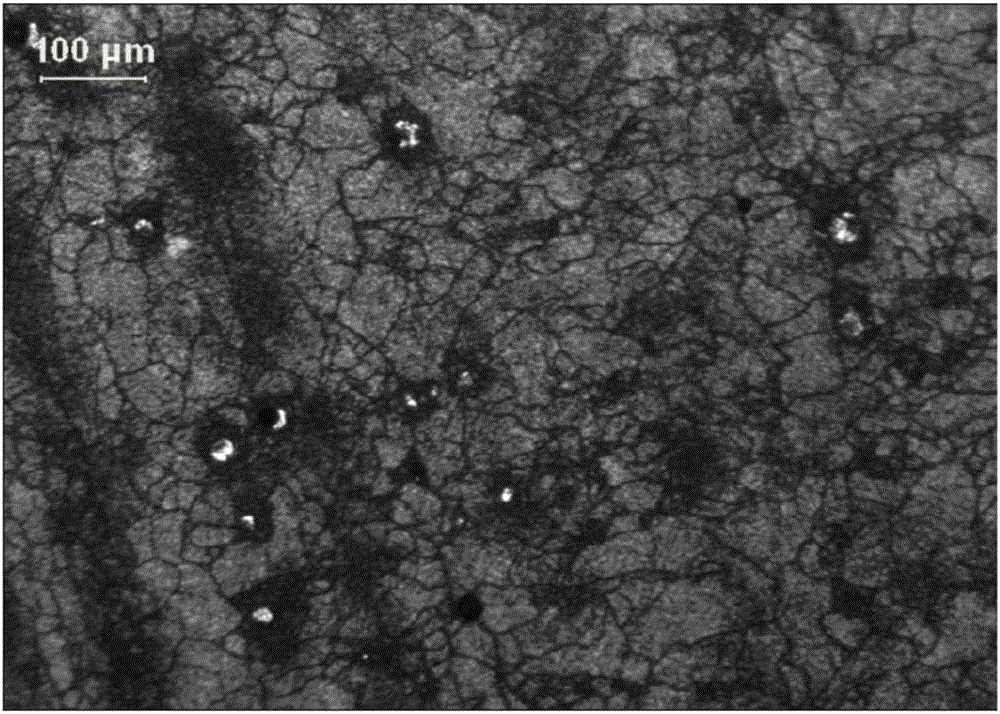

[0034] When the blade does not add pretreatment in the solution treatment process, the blade body, edge plate and root surface of the blade have different degrees of incipient melting defects in the chemical inspection of the blade after solution treatment, which exceeds the requirements of the blade acceptance standard, resulting in blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com