Method for preparing maize polypeptide through synchronous multi-frequency ultrasonic-aided enzymatic hydrolysis by immobilized enzyme

An enzyme immobilized enzyme, multi-frequency ultrasonic technology, applied in the direction of immobilization on/in the organic carrier, fermentation, etc., can solve the problem of difficulty in obtaining enzymatic hydrolysis promotion effect and protein modification effect, and improve the peptide yield. The effect of high rate and activity, high reuse rate and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

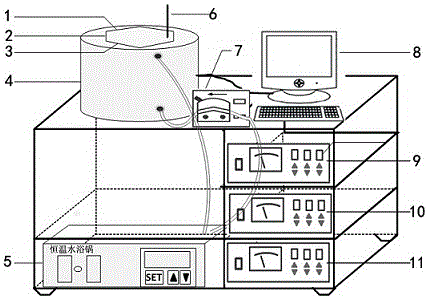

Image

Examples

Embodiment 1

[0026] Synchronous multi-frequency ultrasound-assisted enzymatic hydrolysis of immobilized enzymes to prepare corn polypeptide test. Take 125 g of corn flour, dissolve it in 2.5 L of water according to the ratio of solid to liquid (5% by mass to volume), heat to 60°C, adjust the pH to 8.5, and add 1800 U / g of enzyme. The conditions of synchronous multi-frequency ultrasonic treatment were: 20, 28, 40 kHz three-frequency ultrasonic synchronous work, ultrasonic power density 150 W / L, pulse working time 10 s, intermittent time 5 s, processing time 60 min. After the enzymatic hydrolysis, the immobilized alkaline protease was recovered by filtration, and then centrifuged at 4000 rpm for 15 minutes, the supernatant was taken, concentrated, and freeze-dried to obtain the corn polypeptide product. The measured hydrolysis degree was 18.1%, and the peptide concentration was 10.6 mg / mL , the ACE inhibition rate was 69.2%, and the relative enzyme activity was 18.6%.

Embodiment 2

[0028] The test treatment process was the same as in Example 1, the difference being that 20, 35, and 50 kHz three-frequency ultrasound was used to work synchronously. The degree of hydrolysis of the corn peptide product was 18.6%, the peptide concentration was 9.5 mg / mL, and the ACE inhibition rate was 64.0%. The enzyme activity was 11.7%.

Embodiment 3

[0030] The test treatment process was the same as in Example 1, the difference being that 20, 40, and 60 kHz three-frequency ultrasound was used to work synchronously. The degree of hydrolysis of the corn peptide product was 19.3%, the peptide concentration was 10.4 mg / mL, and the ACE inhibition rate was 68.1%. The enzyme activity was 16.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com