Phytosterol and sterol ester preparing method

A technology of phytosterol esters and phytosterols, which is applied in the field of food engineering, can solve the problems of unsuitability for large-scale industrial production, high product cost, and low production efficiency, and achieve the effects of easy separation, cost resistance to high temperature, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

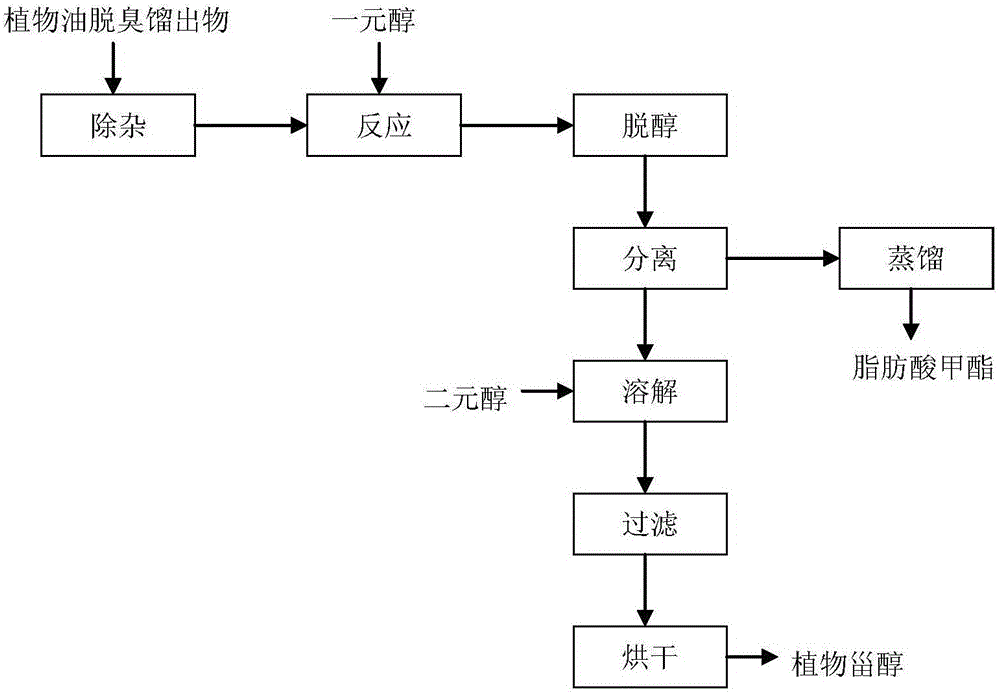

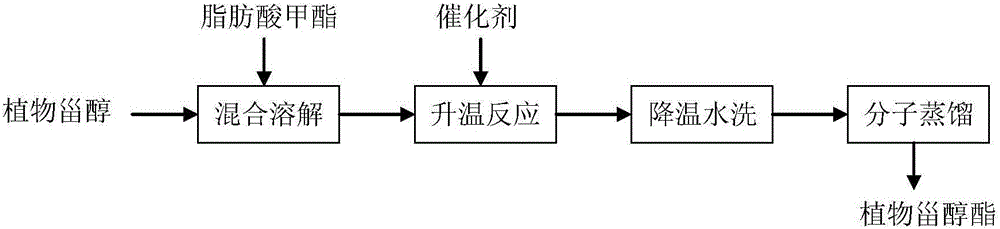

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0045] (1) Adopt corn oil deodorization distillate in the embodiment of the present invention, 1000ml graduated cylinder measures 500ml corn oil deodorization distillate and 1000ml methyl alcohol, add mixer and preheat to 65 ℃ and stir to dissolve and evenly form mixed solution standby; Press 500ml / The flow rate of h passes through the NKC-9 cationic resin column, and the reaction solution collected in 3 hours is put into a 3000ml three-ear bottle; the three-ear bottle is placed on the electric heating mantle, connected to the vacuum condensation reflux device, and the heating is turned on, and the temperature is set at 95°C. Vacuum-0.06Mpa removes the methanol solvent to obtain 510ml of the reaction solution, and takes a sample to detect the acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com