Asymmetric Gemini surfactant containing carboxyl-sulfonic groups and microwave preparation method of asymmetric Gemini surfactant

A technology of surfactants and sulfonic acid groups, which is applied in the field of asymmetric Gemini surfactants containing carboxyl-sulfonic acid groups and its microwave preparation, which can solve the problems of rare surfactants and achieve good market applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

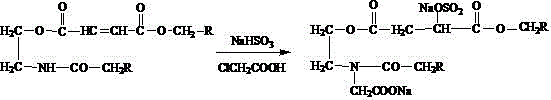

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Weigh 9.8 parts by mass of fatty acid monoethanolamide maleic acid diester, neutralize its pH to 7 with 40% sodium hydroxide solution, add 3.3 parts by mass of disodium dodecyl sulfosuccinate Salt. Weigh 2.2 parts by mass of sodium bisulfite, and make it into a 30% sodium bisulfite solution dropwise into a three-necked flask, and stir the system evenly in a water bath at 70-80°C. The reactants were transferred to a microwave digestion apparatus and reacted for 90 minutes under the conditions of a temperature of 170° C. and a power of 600 W to obtain fatty acid monoethanolamide sulfosuccinic acid diester.

[0034] Step 2: Weigh 3.7 parts by mass of chloroacetic acid to prepare a 30% solution, and adjust the pH of the solution to 7 with sodium hydroxide. Add the above 30% chloroacetic acid solution dropwise to 20.44 parts by mass of fatty acid monoethanolamide sulfosuccinic acid diester, adjust the pH of the system to 7, and stir evenly. The reactant was transfe...

Embodiment 2

[0037] Step 1: Weigh 10.8 parts by mass of fatty acid monoethanolamide maleic acid diester, neutralize its pH to 7 with 40% sodium hydroxide solution, add 4.3 parts by mass of disodium dodecyl sulfosuccinate Salt. Weigh 2.4 parts by mass of sodium bisulfite, and make a 30% sodium bisulfite solution dropwise into a three-necked flask, and stir the system evenly in a water bath at 80°C. The reactant was transferred to a microwave digestion apparatus and reacted for 60 minutes under the conditions of temperature 180°C and power 600W to obtain fatty acid monoethanolamide sulfosuccinic acid diester.

[0038] Step 2: Weigh 3.8 parts by mass of chloroacetic acid to prepare a 30% solution, and adjust the pH of the solution to 7 with sodium hydroxide. Add the above 30% chloroacetic acid solution dropwise to 19.6 parts by mass of fatty acid monoethanolamide sulfosuccinic acid diester, adjust the pH of the system to 7, and stir evenly. The reactant was transferred to a high-throughput ...

Embodiment 3

[0041] Step 1: Weigh 9.3 parts by mass of fatty acid monoethanolamide maleic acid diester, neutralize its pH to 7 with 40% sodium hydroxide solution, add 3.3 parts by mass of disodium dodecyl sulfosuccinate Salt. Weigh 2.25 parts by mass of sodium bisulfite, and make it into a 30% sodium bisulfite solution dropwise into a three-necked flask, and stir the system evenly in a water bath at 75°C. The reactant was transferred to a microwave digestion apparatus and reacted for 90 minutes under the conditions of a temperature of 160° C. and a power of 600 W to obtain fatty acid monoethanolamide sulfosuccinic acid diester.

[0042] Step 2: Weigh 3.4 parts by mass of chloroacetic acid to prepare a 30% solution, and adjust the pH of the solution to 7 with sodium hydroxide. Add the above 30% chloroacetic acid solution dropwise to 18.36 parts by mass of fatty acid monoethanolamide sulfosuccinic acid diester, adjust the pH of the system to 7, and stir evenly. Transfer the reactant to a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com