System for carrying out softening treatment on reverse osmosis concentrated water by means of induced crystallization

A technology of reverse osmosis concentrated water and induced crystallization. It is used in descaling and water softening, water/sludge/sewage treatment, complex/solubilizer treatment, etc. It can solve problems such as environmental impact and water waste, and reduce Emissions, small investment, high environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

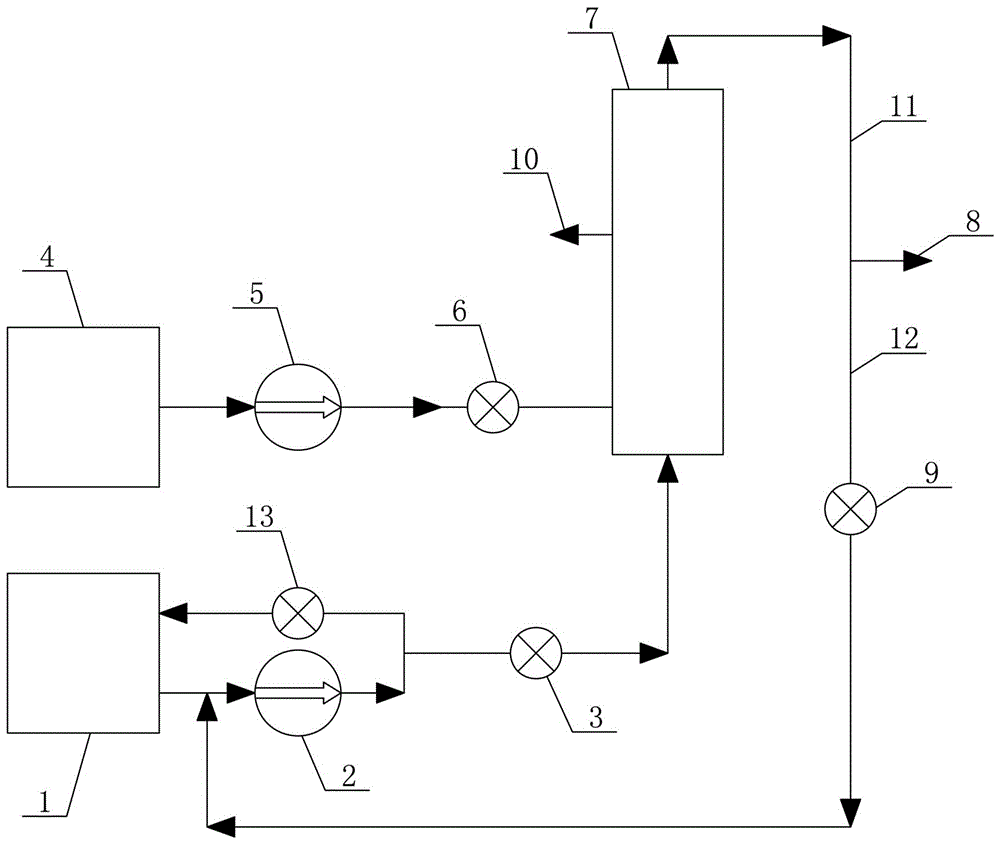

Method used

Image

Examples

Embodiment 1

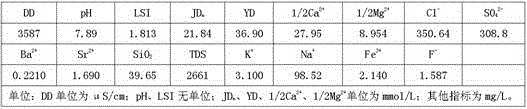

[0020] (1) The average water quality of the primary and secondary concentrated water of #3 and #4 reverse osmosis systems in a plant is shown in Table 1. The content of PTP-0100 antiscalant in system operation is 16mg / L.

[0021] Table 1 Test water quality

[0022]

[0023] (2) Start the feed water pump and adjust the water inlet flow to the preset value. Measure the turbidity of the effluent water every 30s. When the turbidity of the fluidized bed effluent is stable, turn on the dosing pump to add softener, quickly adjust the dosing flow rate to the preset value, and the softening-induced clarification process begins.

[0024] (3) Test water quality according to Table 1, choose NaOH as softener. The amount of softener is represented by the specific consumption of softener (N), and N is defined as the alkalinity of NaOH and test water (JD m ) ratio of moles. In order to guarantee HCO3 - It is completely neutralized with NaOH, and the theoretical value of N is 1.0.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com