Transverse interconnection low-temperature wafer level packaging method specific to radio-frequency MEMS (Micro Electro Mechanical System) device application

A wafer-level packaging and device technology, which is applied in the direction of electric solid-state devices, semiconductor devices, and processes for producing decorative surface effects, can solve the problem that the packaging strength and airtightness of organic materials cannot be guaranteed, increasing process difficulty and process cost , unable to realize the horizontal interconnection of leads, etc., to achieve the effect of strong plasticity, low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

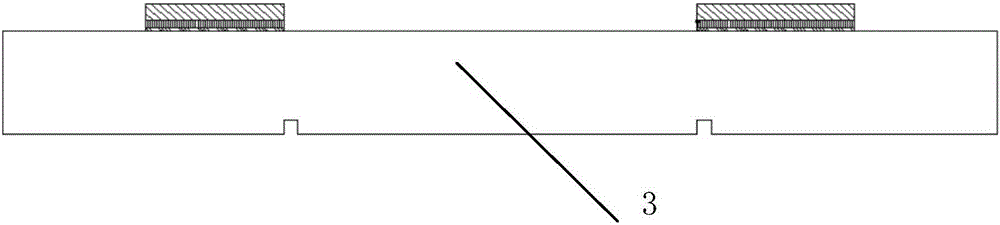

[0058] Such as Figures 1 to 4 The low-temperature wafer-level packaging method for lateral interconnection for the application of RF MEMS devices, which includes the fabrication of the package cover 1, the fabrication of the package substrate 2, and the alignment and bonding of the package cover 1 and the package substrate 2, which is unique at:

[0059] The fabrication of the package cover plate 1 includes the following steps:

[0060] First, choose a silicon wafer, or non-silicon material such as glass, or GaN, as the package cover material. After cleaning, a bonding wire pattern mask is photoetched.

[0061] Next, 20 to 50 nm of Ti is used as an adhesion layer by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com