A kind of plastic film processing equipment

A plastic film and processing equipment technology, applied in the field of plastic film, can solve the problems affecting the quality of film products, wrinkles caused by film folding, and huge dry crystallization treatment, so as to facilitate ductility and tension, improve wrinkle resistance and firmness , Improve extrusion efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

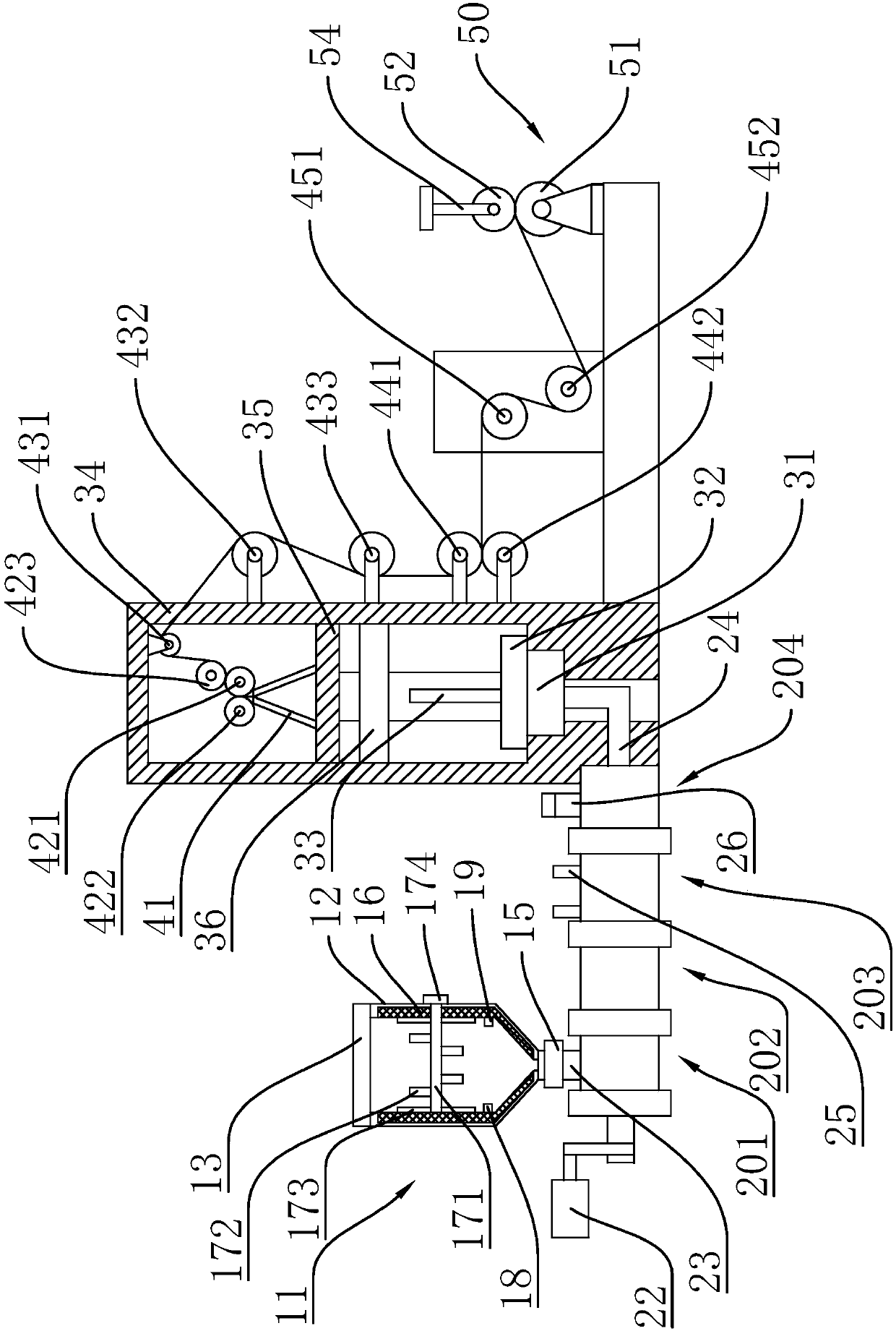

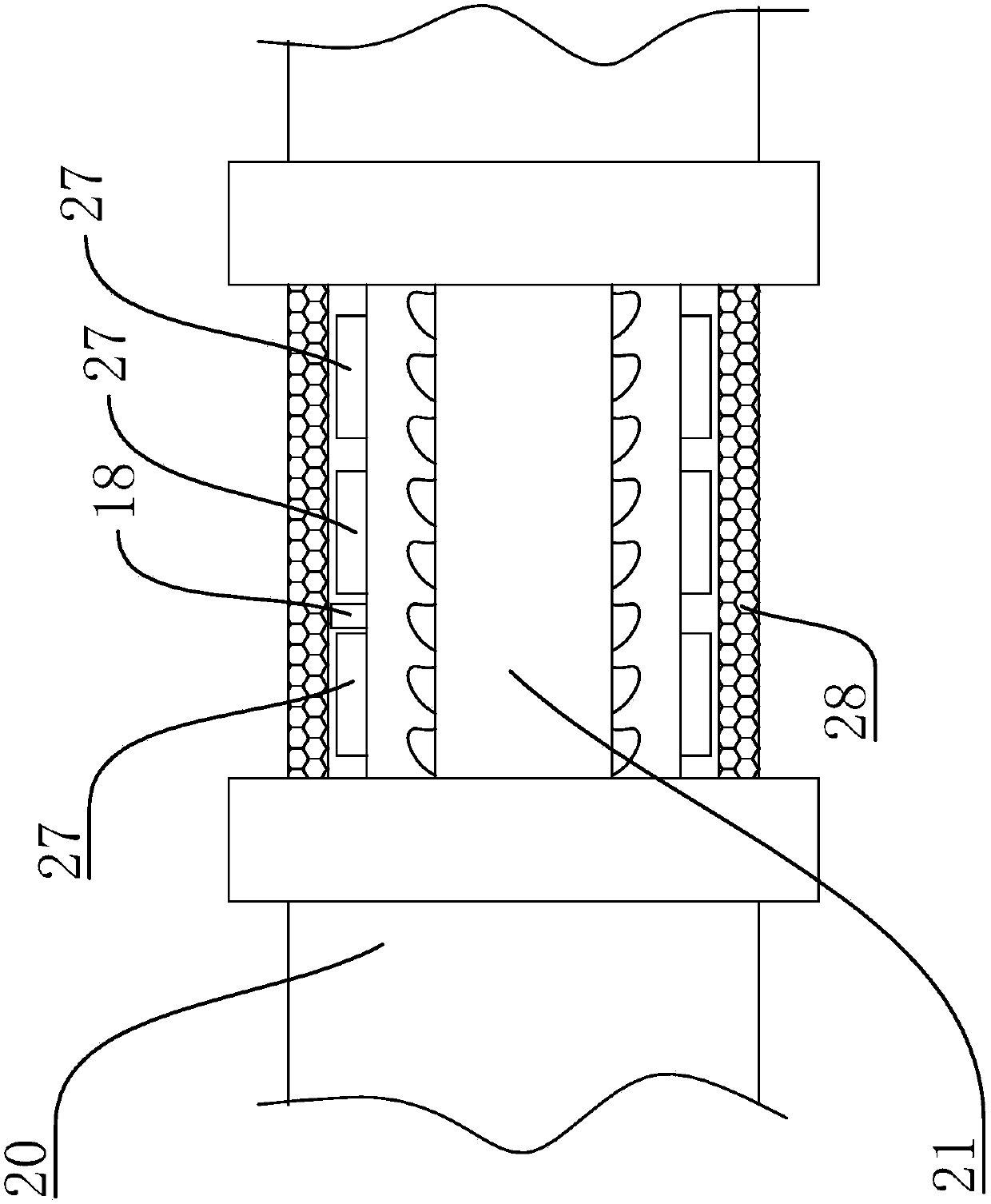

[0033] Such as Figure 1 to Figure 4 As shown, the present invention provides a kind of plastic film processing equipment, comprises film blowing mechanism, traction mechanism, winding mechanism 50 and a plurality of extruding mechanisms, and film blowing mechanism comprises die head 31, air ring 32 and frame 34, and mold The head 31 has multi-layer flow channels, and each layer of flow channels is connected to an extrusion mechanism; the air ring 32 is arranged above the die head 31, and the air ring 32 has uniformly distributed air inlets, and the air inlets are connected to the air inlet pipes. The top of the air ring 32 is provided with a corona machine 36, and the center of the air ring 32 is vertically provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com