A semi-automatic welding device

A semi-automatic welding and welding gun technology, applied in welding equipment, transportation and packaging, manufacturing tools, etc., can solve the problems of difficult operation of welding equipment and poor welding quality, so as to improve welding quality, reduce operation difficulty, and make verticality easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make those skilled in the art better understand the technical solution of the present invention, the solution will be further described in detail below with reference to specific embodiments.

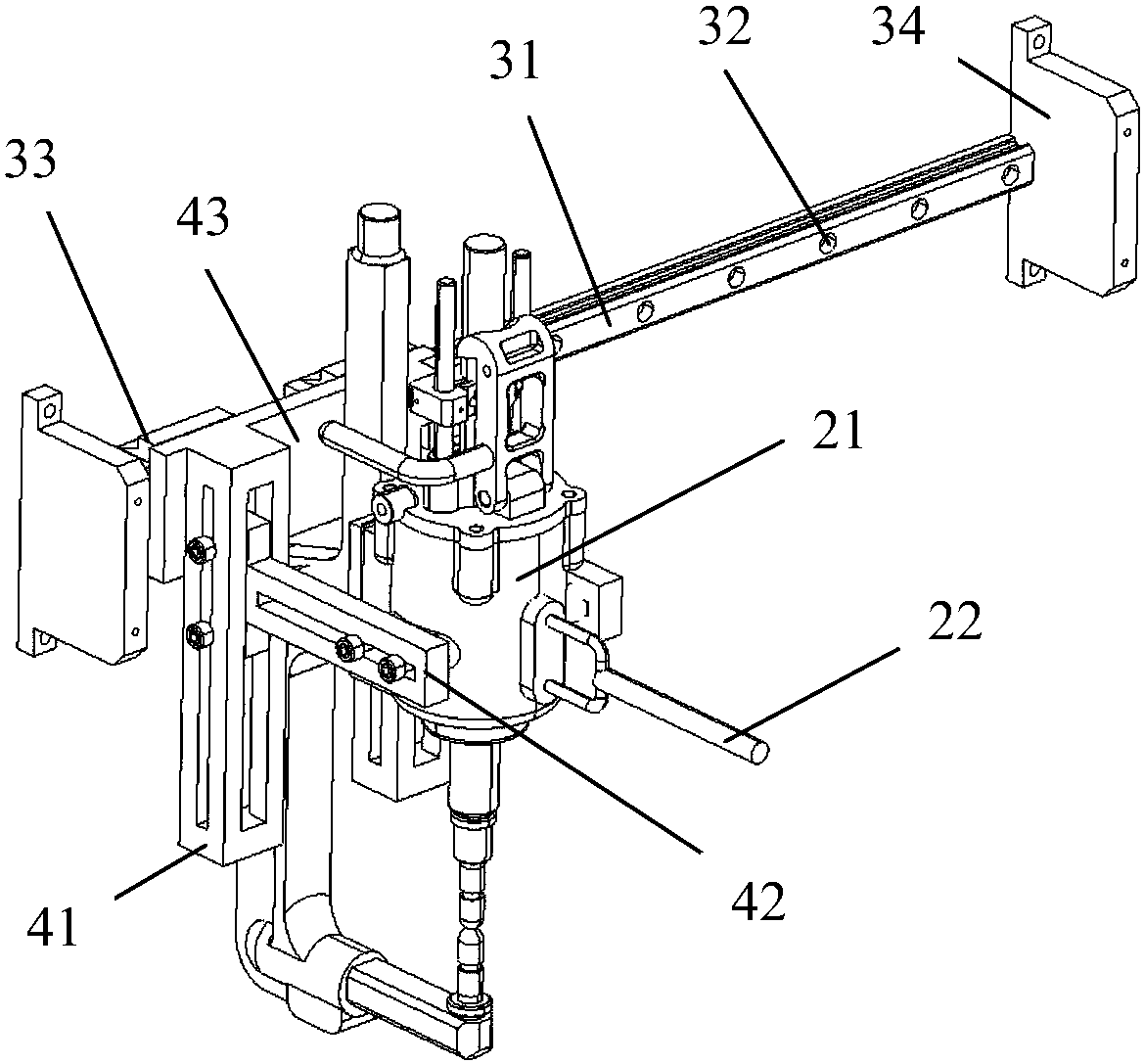

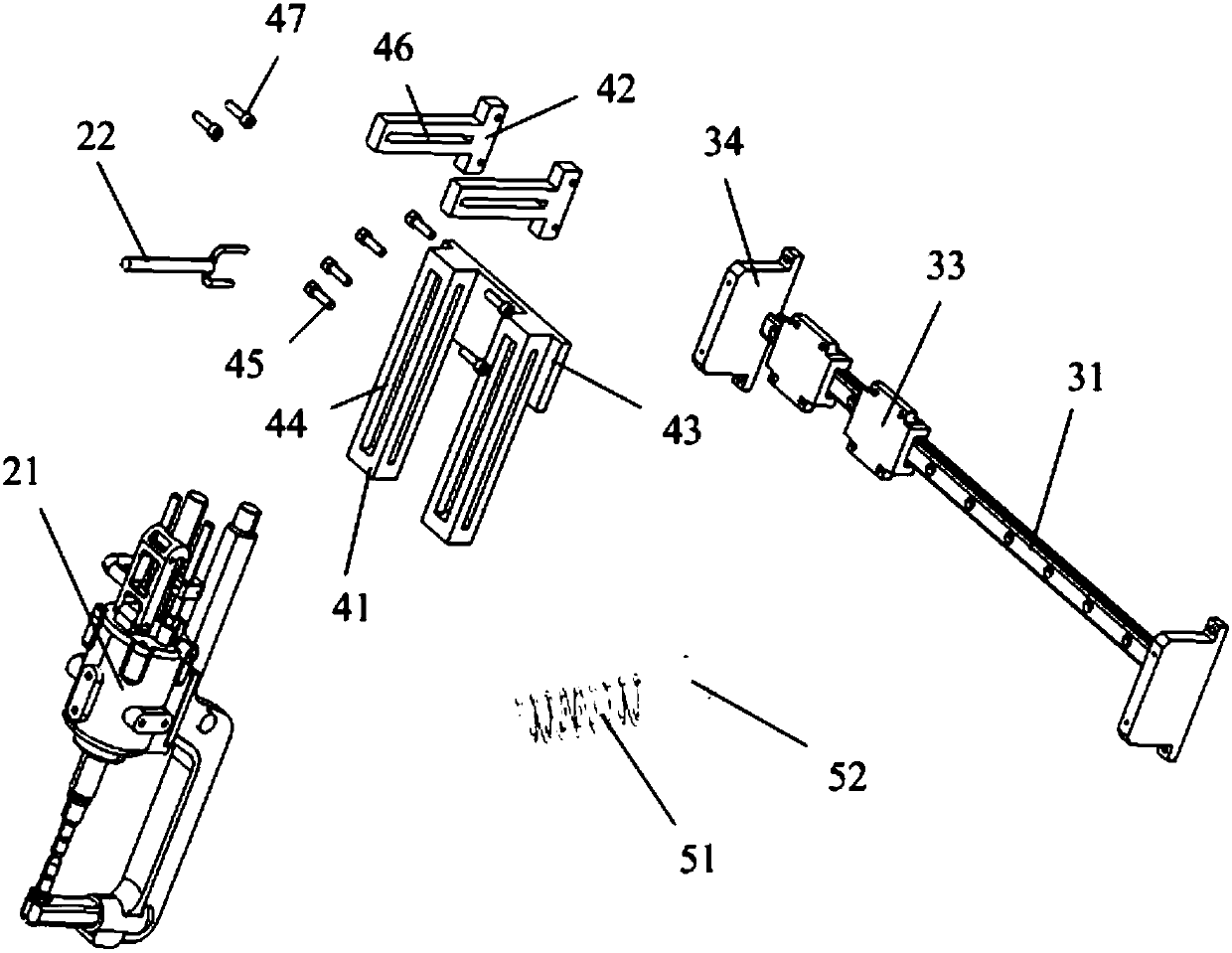

[0029] like Figure 2 to Figure 5 As shown, the embodiment of the present invention provides a semi-automatic welding device, which includes a welding tong 21, a handle 22 arranged on the welding tong 21, a connecting mechanism and a sliding rail mechanism, wherein the sliding rail mechanism includes a welding control switch 35, a sliding rail 31. The sliding block 33 slidingly matched with the sliding rail 31 and the mounting bases 34 arranged at both ends of the sliding rail 31. The mounting bases 34 are used to connect with the fixture 61; the sliding rail 31 is provided with a plurality of mounting holes 32, each of which Evenly distributed in the extending direction of the slide rail 31; each mounting hole 32 is provided with a welding control switch 35; The tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com