Hydrolyzed D90 demineralized whey powder and preparation method thereof

A technology of desalted whey powder and desalted whey, applied in whey, dairy products, applications, etc., can solve the problems of low allergy, low degree of hydrolysis, easy absorption, etc., to reduce the impact of protein allergies and improve the absorption of protein nutrition Efficiency, effect of improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

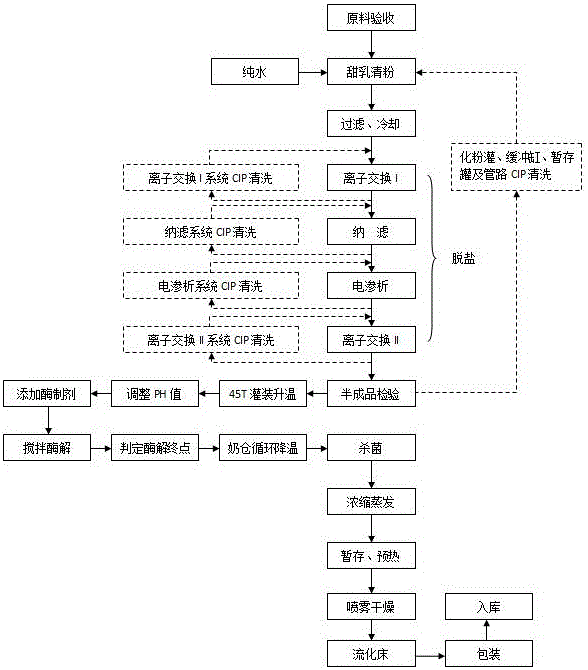

Image

Examples

Embodiment 1

[0023] First, the preparation of D90 desalted whey liquid: the D90 desalted whey liquid is prepared by adding sweet whey powder into water and then desalinated to remove minerals. The hydrolysis temperature: 50°C, the hydrolysis time: 3 hours, and the D90 desalted whey liquid is prepared according to the concentration of 20%. Whey liquid, namely: 20 grams of sweet whey powder, 80 grams of water to prepare 100 grams of D90 desalted whey liquid, take 99 grams of D90 desalted whey liquid, 0.0613 grams of protease preparation, and 0.9387 grams of acidity regulator; in sweet whey powder After adding water to dissolve and desalting treatment, before making D90 desalted whey liquid, perform CIP cleaning on the used chemical powder tank, buffer tank, temporary storage tank and pipeline;

[0024] (1) Filter and cool the sweet whey powder solution;

[0025] (2) Perform ion exchange I on the sweet whey liquid; perform CIP cleaning on the ion exchange system before performing ion exchange...

Embodiment 2

[0046] First, the preparation of D90 desalted whey liquid: the D90 desalted whey liquid is prepared by adding sweet whey powder into water and then desalinated to remove minerals. The hydrolysis temperature: 50°C, the hydrolysis time: 3 hours, and the D90 desalted whey liquid is prepared according to the concentration of 20%. Whey liquid, namely: 20 grams of sweet whey powder, 80 grams of water to prepare 100 grams of D90 desalted whey liquid, take 99 grams of D90 desalted whey liquid, 0.0613 grams of protease preparation, and 0.9387 grams of acidity regulator; in sweet whey powder After adding water to dissolve and desalting treatment, before making D90 desalted whey liquid, perform CIP cleaning on the used chemical powder tank, buffer tank, temporary storage tank and pipeline;

[0047] (1) Filter and cool the sweet whey powder solution;

[0048] (2) Perform ion exchange I on the sweet whey liquid; perform CIP cleaning on the ion exchange system before performing ion exchange...

Embodiment 3

[0069] First, the preparation of D90 desalted whey liquid: the D90 desalted whey liquid is prepared by adding sweet whey powder into water and then desalinated to remove minerals. The hydrolysis temperature: 50°C, the hydrolysis time: 3 hours, and the D90 desalted whey liquid is prepared according to the concentration of 20%. Whey liquid, namely: 20 grams of sweet whey powder, 80 grams of water to prepare 100 grams of D90 desalted whey liquid, take 99 grams of D90 desalted whey liquid, 0.0427 grams of protease preparation, and 0.9573 grams of acidity regulator; in sweet whey powder After adding water to dissolve and desalting treatment, before making D90 desalted whey liquid, perform CIP cleaning on the used chemical powder tank, buffer tank, temporary storage tank and pipeline;

[0070] (1) Filter and cool the sweet whey powder solution;

[0071] (2) Perform ion exchange I on the sweet whey liquid; perform CIP cleaning on the ion exchange system before performing ion exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com