Transparent conductive laminated body and touch panel provided with transparent conductive laminated body

一种透明导电性、触摸面板的技术,应用在绝缘载体上的导电层、涂层、电子器材等方向,能够解决透明导电膜与接地电极短路、透明导电膜碎裂等问题,达到抑制离子迁移、可靠性优良、耐久性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

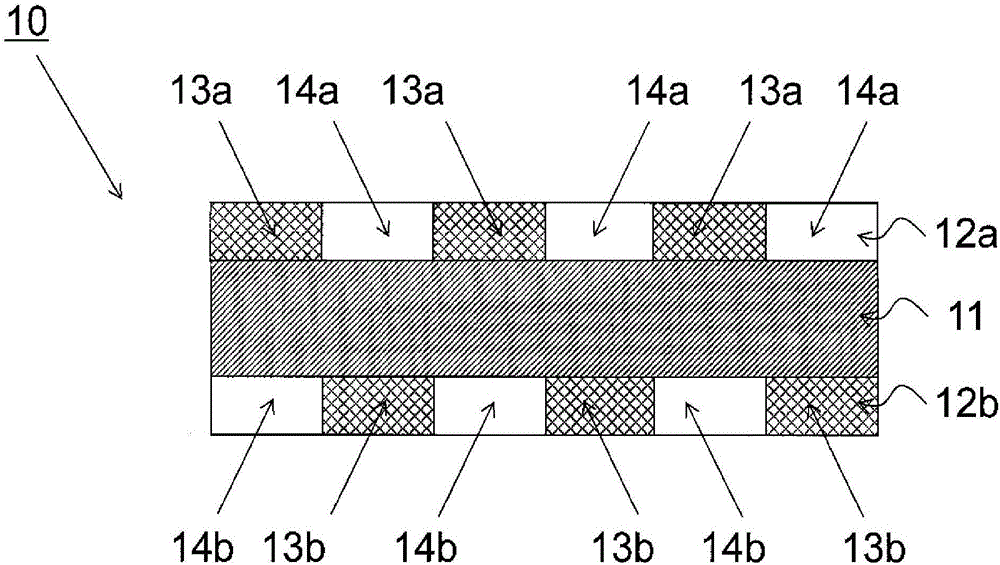

[0126] A UV curable resin was coated on one side of a PET substrate (75 μm), and a metal layer made of fibrous metal was formed thereon by a die coating method. Next, a solution containing an acrylic monomer as a main component was applied by a micro-gravure coating method so as to have a film thickness of 70 nm, and cured by UV irradiation to obtain a transparent conductive layer. A metal layer and a transparent conductive layer were also formed on the opposite side of the PET substrate by the same method. Next, a negative resist is applied by photolithography, after curing by UV irradiation, etching is performed with hydrochloric acid (0.1%), and the resist is stripped with sodium hydroxide solution (1%) to perform patterning. Forming and producing a plurality of strip-shaped conductive regions. In each of the strip-shaped conductive regions, a conductive paste based on epoxy resin and silver was used to form lead wires by screen printing, and a transparent conductive lamin...

Embodiment 2

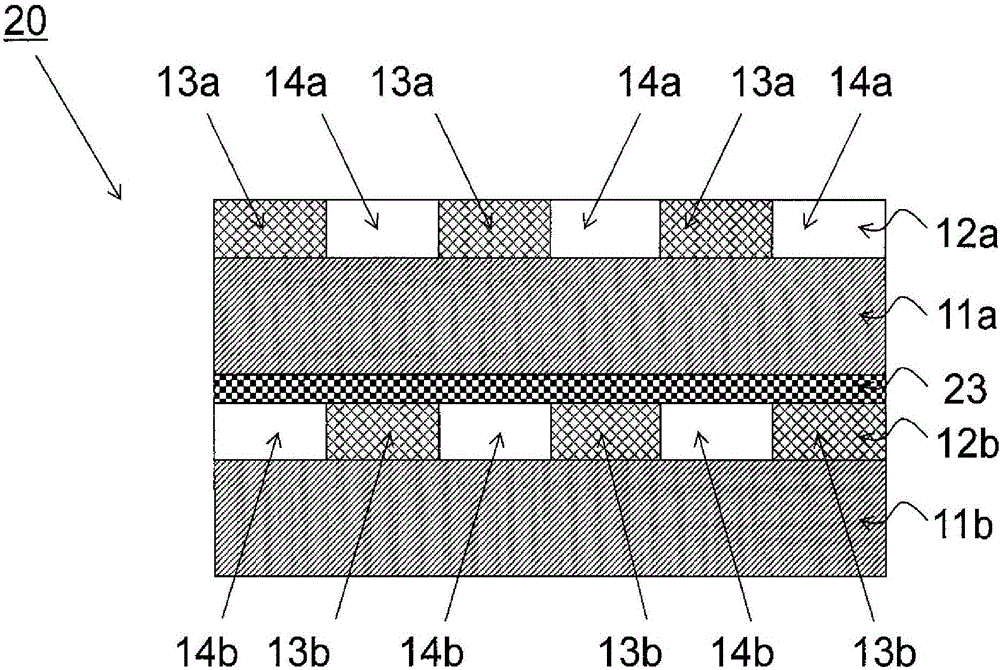

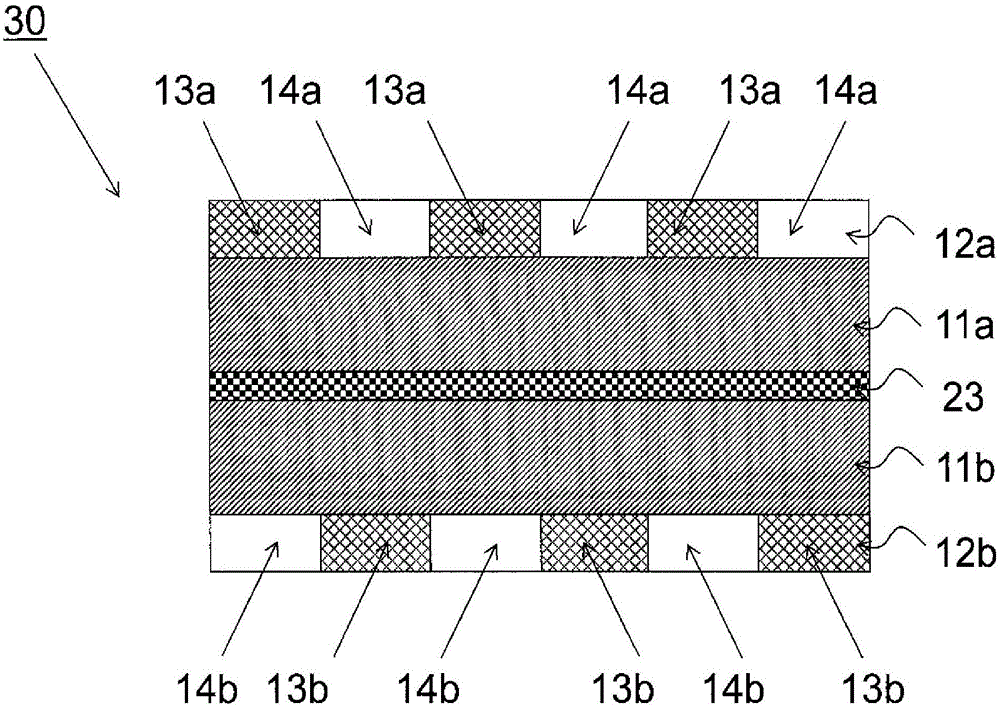

[0135] produced with Figure 18 The same layers constitute the touch panel 200 . Figure 19 is a plan view showing the electrode portion of the touch panel 200, and a schematic cross-sectional view taken along the B line is Figure 18 . Using PET (125 μm) as the substrate 11, UV curable transparent acrylic resin added with 20 wt% of UV absorber was microgravure coated on both sides, dried and UV cured, thereby forming the resin layer 2 as A thickness of 5 μm is formed on both surfaces of the substrate 11 . On both sides of the obtained base material, as the material of the transparent electrode layers 12a, 12b, the transparent electrode layers 12a, 12b were formed by coating silver nanowires by slot die coating so that the square resistance became 100Ω / □. 12b, similarly, a UV curable transparent acrylic resin was applied to a thickness of 130 nm to form a cured film.

[0136] For the substrate on which the transparent electrode layers 12a, 12b are formed on both sides, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact resistance | aaaaa | aaaaa |

| heat shrinkage ratio | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com