A positioning method of engine cylinder block casting based on machine vision

A technology of engine cylinder and machine vision, applied in instruments, image analysis, image enhancement and other directions, can solve the problems of obtaining image shadows, rough casting surface, through hole deformation, etc., to avoid local distortion, heavy weight, and avoid shadows. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and specific embodiments.

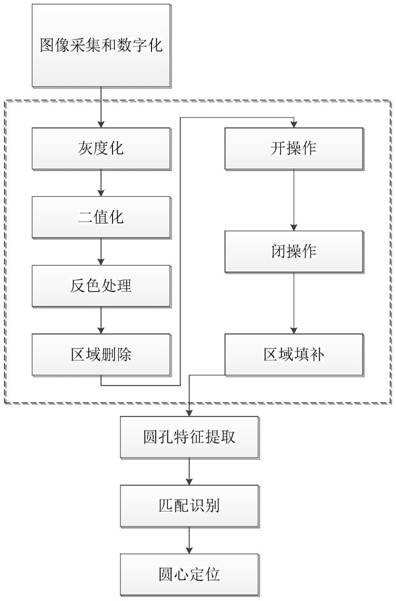

[0033] Such as figure 1 As shown, the method of the present invention includes the following steps:

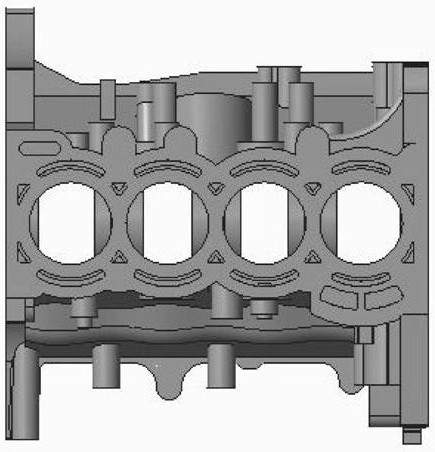

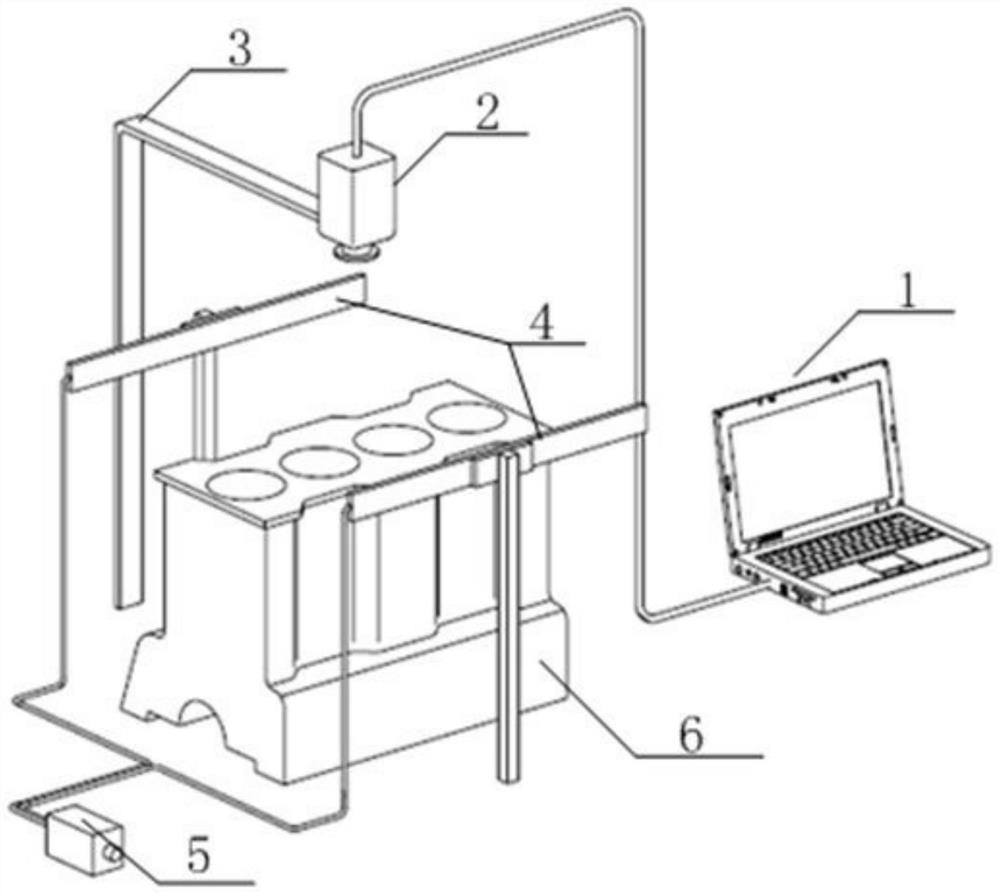

[0034] (1) Collect engine cylinder block images: the cylinder block has a large volume, rough surface, and the cylinder block itself has deep through holes. The images obtained by ordinary methods have a lot of shadows around the through holes, which are not conducive to the positioning of the through holes, such as Figure 4 Shown. Pass as figure 2 The visual positioning system shown selects the appropriate light source, lighting method, camera and lens to obtain the original image highlighting the grasping characteristics of the large casting cylinder. Specifically: a bar-type LED light source 4 is used for surface illumination of a larger detected object. The lighting method is double-sided low-angle lighting. The light source angle is adjusted by the light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com