Doped gas-sensitive material having composite structure and used for NO2 gas, gas-sensitive element, production method of gas-sensitive element and application of gas-sensitive material

A technology of composite structure and doped gas, applied in the direction of material resistance, etc., can solve the problems of being easily interfered by other gases, high power requirements of instruments and equipment, insufficient response and recovery capabilities, etc., and achieve low cost of raw materials and instruments , The process parameters are easy to control, avoiding the effect of uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Porous doped gas-sensing material and its preparation

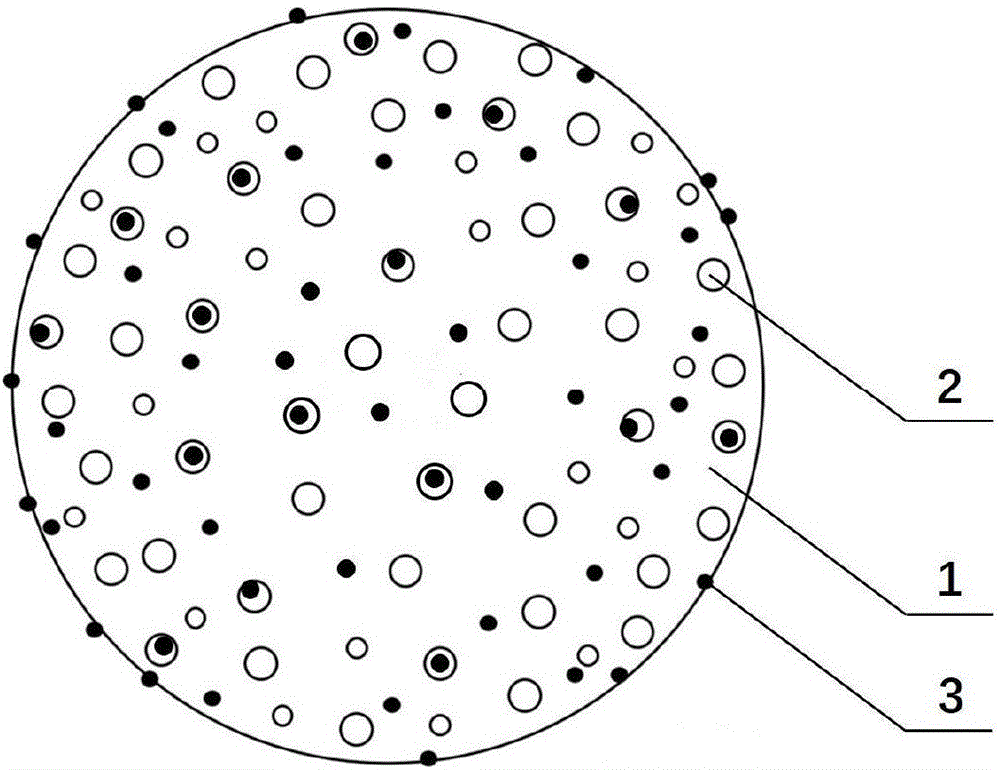

[0047] a NO 2 The gas-doped gas-sensing material with a composite structure is composed of a matrix and a doping phase, and the matrix is SnO with a porous structure 2 Spherical particles, doping phases are distributed on the surface of the matrix and in the pores; the doping phases are Sb 2 o 5 Flaky or spherical particles, the molar ratio of the doping phase to the matrix material is 1 mol%. The doped gas-sensing material is spherical particles with an average diameter of 300-1600nm.

[0048] Preparation steps:

[0049] 0.35g matrix raw material SnCl 4 ·5H 2 O, 20mg doping phase raw material SbCl 3 1. Add 0.5g of surfactant polyvinylpyrrolidone into anhydrous methanol and stir until it is completely dissolved. The stirred clear liquid is put into the reactor and kept at 180°C for 3 hours to make the raw materials undergo hydrolysis reaction inside the reactor. The obtained hydrolyzate was separated b...

Embodiment 2

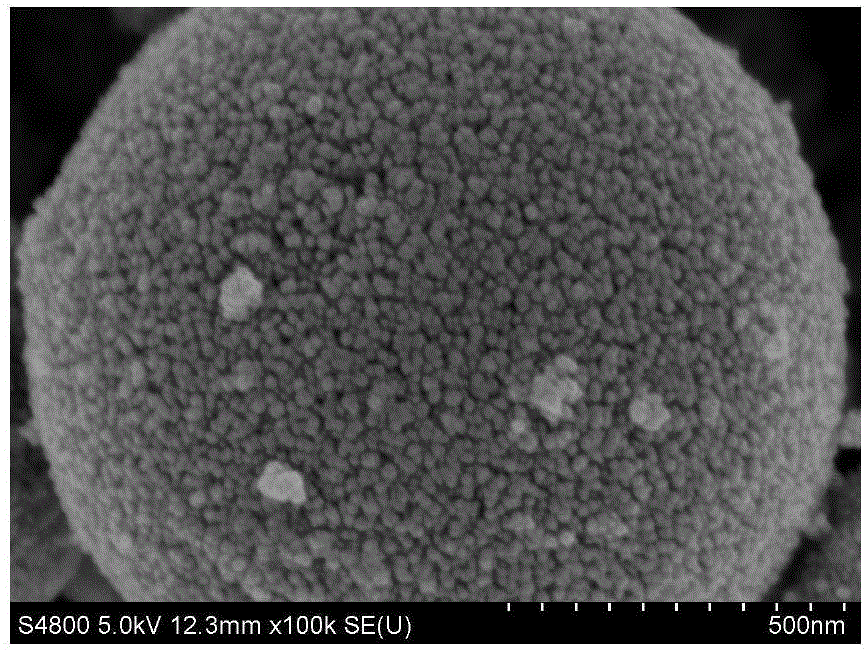

[0056] Example 2, as described in Example 1, the difference is: no doping phase raw material is added in step (1), and undoped SnO is prepared separately according to the same conditions 2 Matrix material. The separately synthesized matrix material is ultrasonically dispersed in methanol, and the doping raw material SbCl is added to the obtained suspension 3 , stirred for 20 min and added dropwise 10-20 ml of ammonia water with a mass fraction of 25% in the process. The resulting precipitate was separated by centrifugation, washed 5 times with methanol, and dried at 80°C for 8 hours. The dried samples were finally calcined in a muffle furnace at 400 °C for 2 h to make the doped phase precursor Sb(OH) 3 The reaction converts to Sb 2 o 5 . The resulting Sb 2 o 5 Doped porous nanosphere SnO 2 Scanning electron microscopy analysis of the surface morphology showed that Figure 4 shown by Figure 4 It can be seen that the two-step synthesis did not change the structure and...

Embodiment 3

[0058] Example 3, Gas Sensitive Detection of Different Doping Phase Concentrations

[0059] As described in Example 1, the difference is that the molar ratios of the dopant phase to the matrix material in step (1) are 0.5 mol%, 2 mol%, and 5 mol%, respectively. At 80℃, 10ppm NO 2 Gas sensitivity test results under gas conditions are as follows: Image 6 It can be seen from the figure that the gas-sensing performance of the material changes with the amount of doped phase, but they are all the same as those for NO at 80°C. 2 Gas has a relatively good response. Its response value ranges from 500-1000. With the increase of doping phase concentration, the response time is 44s, 20s, 33s and 85s, and the recovery time is 103s, 75s, 114s and 91s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com