LED lamp filament lamp with built-in power source and thermal radiation material

An LED filament lamp and LED filament technology, applied in the field of lighting, can solve the problems of cumbersome processes, difficult heat dissipation, limited space, etc., and achieve the effects of improving heat dissipation effect, improving production efficiency, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand the present invention.

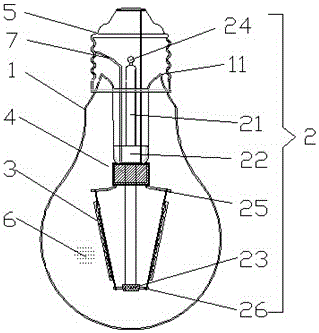

[0023] Such as figure 1 as shown,

[0024] A power supply built-in LED filament lamp with heat radiation material, comprising a bulb shell 1, a stem 2 with a bracket 22, at least one LED filament 3, a driver 4 and a lamp cap 5, the bulb shell 1 and the stem 2 are vacuum Seal to form a vacuum-sealed cavity; a high thermal conductivity gas 6 is arranged in the vacuum-sealed cavity; the stem 2, LED filament 3 and driver 4 are all located inside the vacuum-sealed cavity; the bracket 22 is located at the end of the stem 2, and the driver 4 is fixed On the upper part of the support 22; the lower end of the support 22 is provided with a wire 26; the upper end of the support 22 is provided with an electrode lead-out line 25; one end of the LED filament 3 is connected in series with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com