Woven multi-purpose exhaust-suction dual-use pipe and preparation technology thereof

A multi-purpose and dual-purpose technology, used in the field of suction pipes, can solve the problems of easy aging, low strength, high pressure resistance, etc., and achieve the effects of good solvent resistance and aging resistance, low transportation resistance and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation process for a braided multi-purpose exhaust and suction pipe, comprising the following steps:

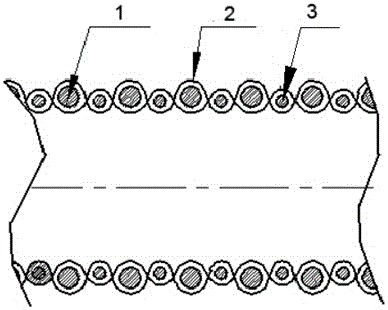

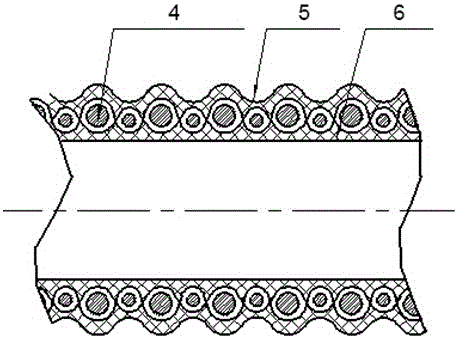

[0030] (1) First, 15 shares of 29.5tex polyester thread are plied together to obtain polyester thread a, then 20 shares of 29.5tex polyester thread are plied together to obtain polyester thread b, and then polyester thread a and polyester thread b are plied together to obtain warp thread 2 , a polyester monofilament 1 with a diameter of 4mm and a polyester monofilament 3 with a diameter of 1.5mm are interwoven with the warp by a double-shuttle circular loom to form a middle reinforced skeleton layer 4, and the gained reinforced skeleton layer weft thread density 31 wefts per 10 cm, and 64 warps per 10 cm;

[0031] (2) Preheat the barrel and mold 7 of the extruder to 180°C for 3 hours, then put the mixture of polyurethane resin, anti-aging agent, carbon black, lubricant, anti-fungal agent and light stabilizer into In the feeding device of the conical twin-screw ...

Embodiment 2

[0035] A preparation process for a braided multi-purpose exhaust and suction pipe, comprising the following steps:

[0036] (1) Polyester thread a obtained by plying 15 shares of 29.5tex polyester thread, then 20 shares of 29.5tex polyester thread to obtain polyester thread b, and then polyester thread a and polyester thread b to obtain warp thread 2, A polyester monofilament 1 with a diameter of 3 mm and a polyester monofilament 3 with a diameter of 1 mm are interwoven with the warp by a double-shuttle circular loom to form a middle reinforced skeleton layer 4, and the weft density of the obtained reinforced skeleton layer is 32 wefts per 10 cm, and 60 warps per 10 cm;

[0037] (2) Preheat the barrel and mold 7 of the extruder to 220°C for 2 hours, and then put the mixture of polyurethane resin, anti-aging agent, carbon black, lubricant, anti-fungal agent and light stabilizer into the In the feeding device of the conical twin-screw extruder;

[0038] (3) Put one end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com