Novel absorber capable of effectively avoiding eccentric abrasion of connecting rod

A shock absorber and connecting rod technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of aggravated mechanical partial wear and accelerated wear of connecting rods, so as to prolong life and prevent partial wear. Grinding, avoiding the effect of partial grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

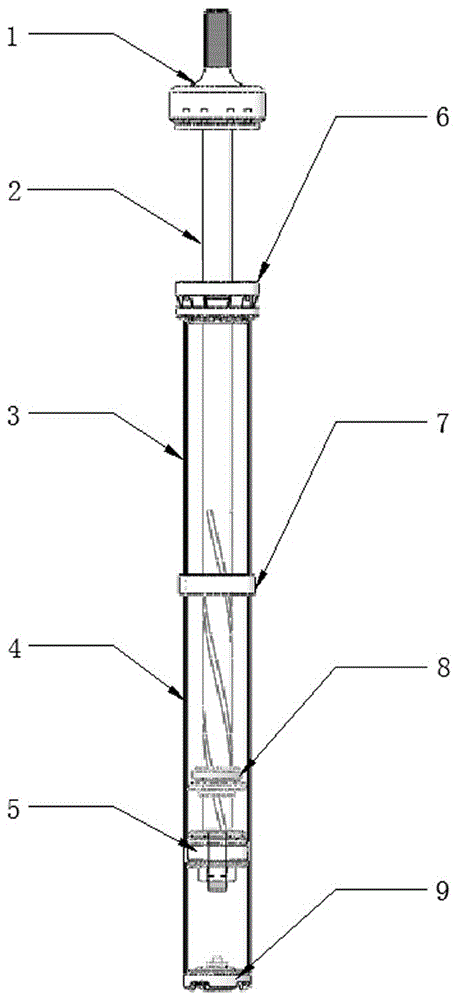

[0019] The structure of the novel shock absorber that can effectively avoid the eccentric wear of the connecting rod will be described in detail below in conjunction with the accompanying drawings.

[0020] see Figure 1 to Figure 9 , the present invention can effectively avoid the new shock absorber of the connecting rod eccentric wear, including the inner cylinder (working cylinder) of the shock absorber, the connecting rod 2 passing through the inner cylinder, the guide 6, the support ring and the recovery buffer block 8. Process at least two threads 13 with a semicircular cross-section on the surface of the connecting rod 2 upward from the lower end. The helix angle of the threads 13 must be large enough and self-locking cannot occur. The inner cylinder is composed of an upper inner cylinder 3 and a lower inner cylinder 4 connected by a round nut 7, the thread of the round nut 7 matches the thread 13 on the connecting rod 2, and the outer diameter of the round nut 7 is lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com