Digital servo hydraulic motor

A hydraulic motor, digital technology, applied in servometer circuits, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve problems such as limited applications, achieve easy integration and linkage, increase output power, and achieve integration and linkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

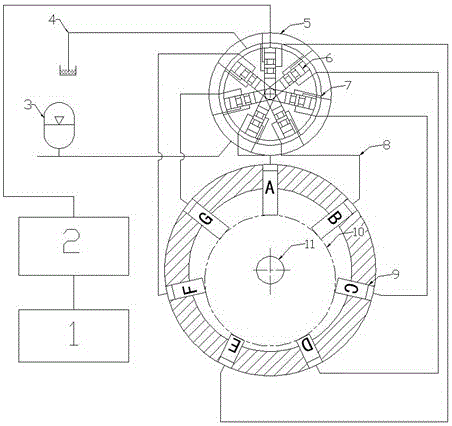

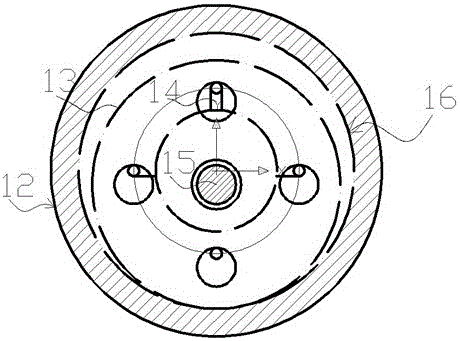

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 shown. In the digital control system 1, the outgoing signal is amplified by the power amplifier 2 and reaches the stepper motor of the rotary oil distribution valve 6 to control the movement of the stepper motor. The accumulator 3 is connected with the oil supply circuit, and the oil discharge groove 7 is connected with the oil return circuit 4 . In order to make the structure simple, an oil supply tank 5 is designed inside the rotary oil distribution valve, and the pressure oil is in the oil supply tank. Whenever an oil distribution piston moves to make the oil supply pipeline 8 communicate with the oil supply tank 5, the pressure oil flows to the plunger 9 . Similarly, the equipped valve is provided with an oil discharge groove 7, and when the slide valve 6 moves so that the oil supply pipeline 8 communicates with the oil discharge groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com