Moving-iron electromagnet

An electromagnet and moving iron technology, applied in the direction of electromagnets and electromagnets with armatures, can solve the problems of large mass of the movable part of the armature, high requirements for winding coils of the moving coil, and cramped space for the armature, etc., to achieve good control High performance, compact structure, heat reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

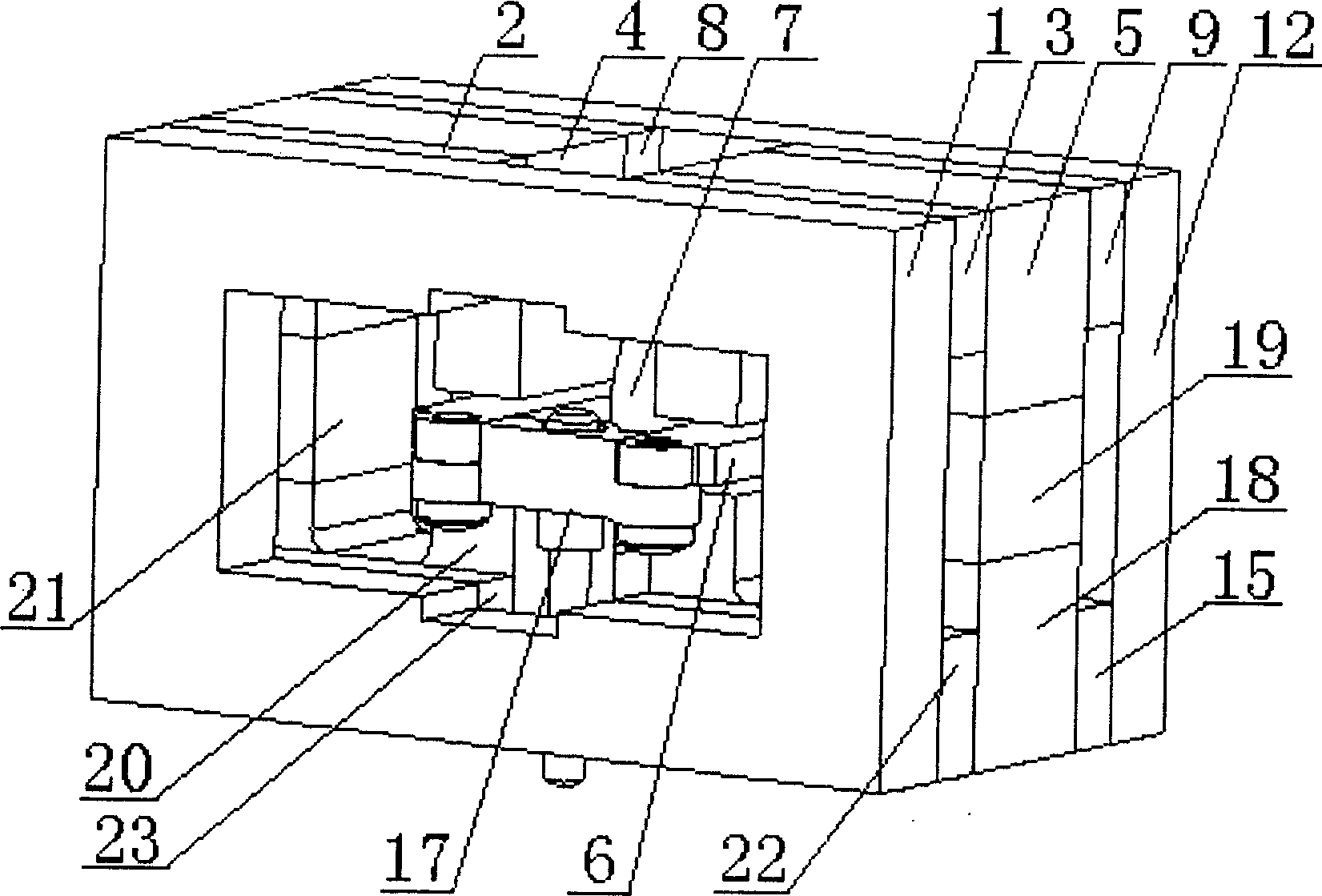

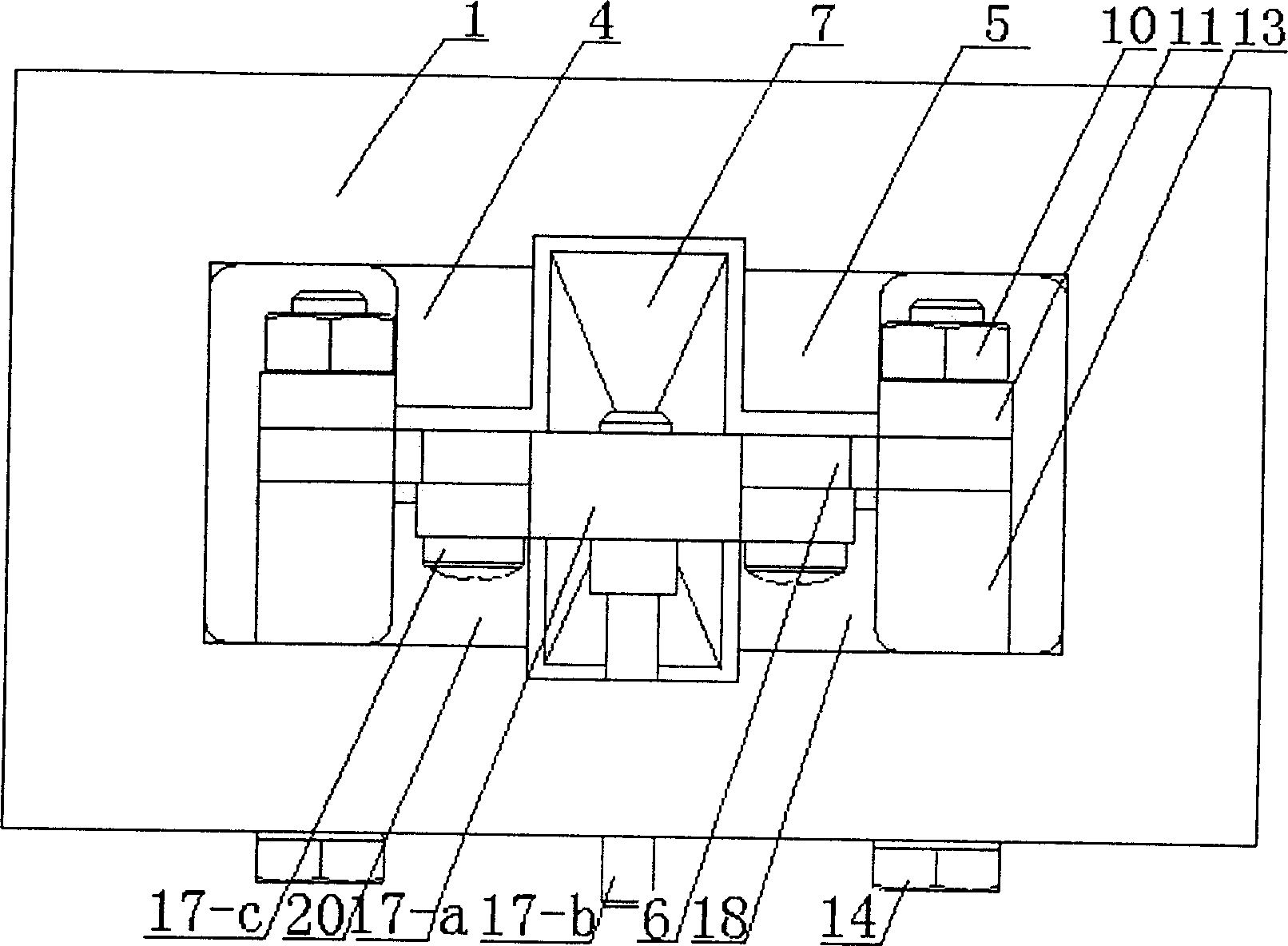

[0024] like Figure 1 to Figure 7 As shown, the present invention includes the first layer of the magnetically conductive plate 1 in turn, and the middle hollow is arranged with a pair of corners with magnetically conductive blocks 2, 22 and the other diagonally with a second layer of non-magnetically conductive blocks 3, 23, One side hollowed out in the middle is made up of yoke 4, magnetic steel 21, yoke 20 and the other side is made up of another yoke 5, magnetic steel 19, yoke 18. The magnetic permeable blocks 8, 15 and the fourth layer of the magnetic permeable blocks 9, 16 are arranged diagonally, and the fifth layer of the other magnetic permeable plate 12 is combined. The hollowed-out space in the middle formed by the combination of five floors is equipped with such Figure 11 As shown in the "Π" shaped armature, the middle arm 6-c of the armature is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com