A method for gob-side entry retention with high-water material and thin-wall composite support

A technology with thin walls and composite support, which is applied in the field of gob-side entry retention in coal mines, can solve the problems of increased cost of entry entry retention and increased material consumption, so as to save material consumption, increase wall confining pressure, and facilitate gas drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

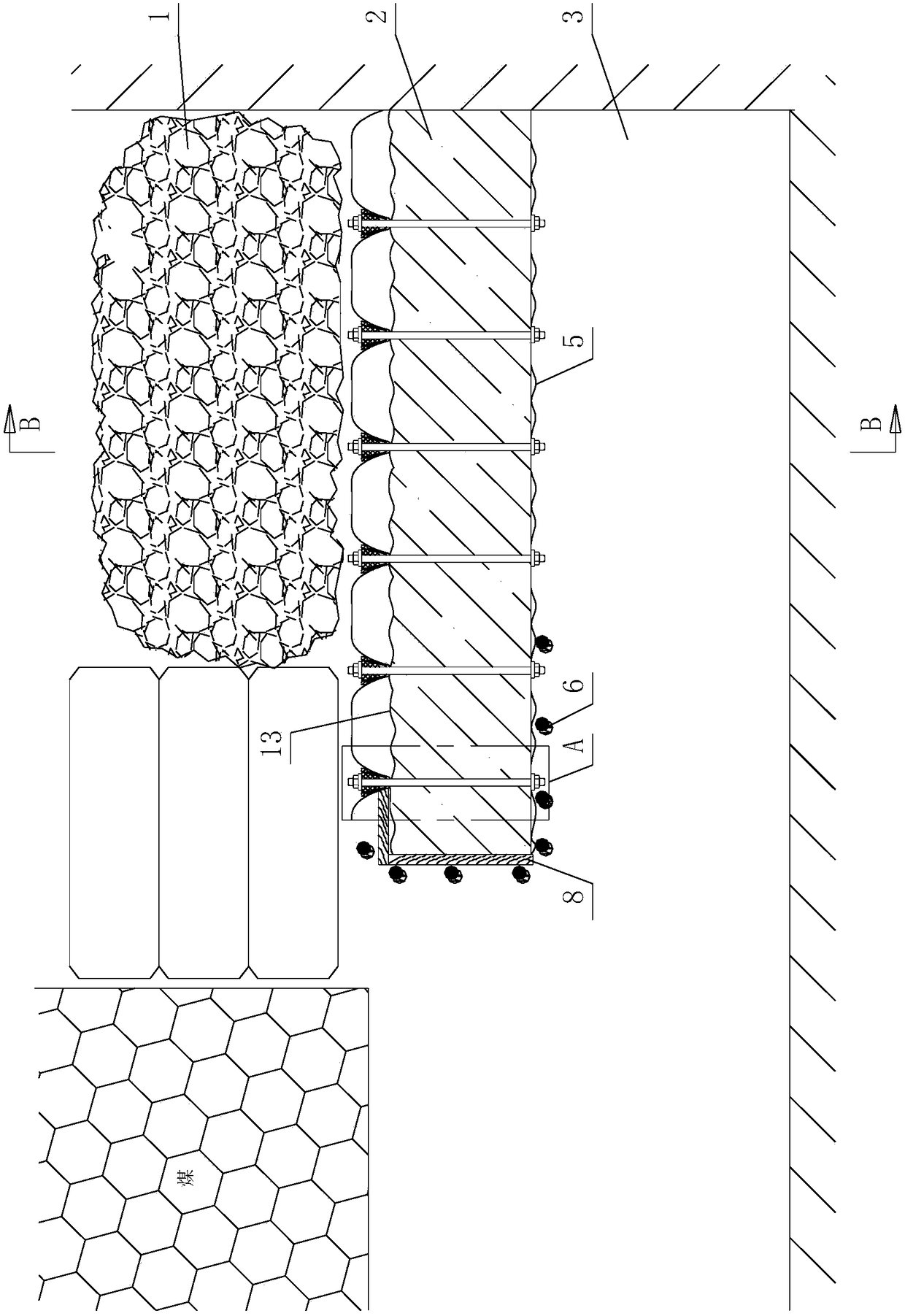

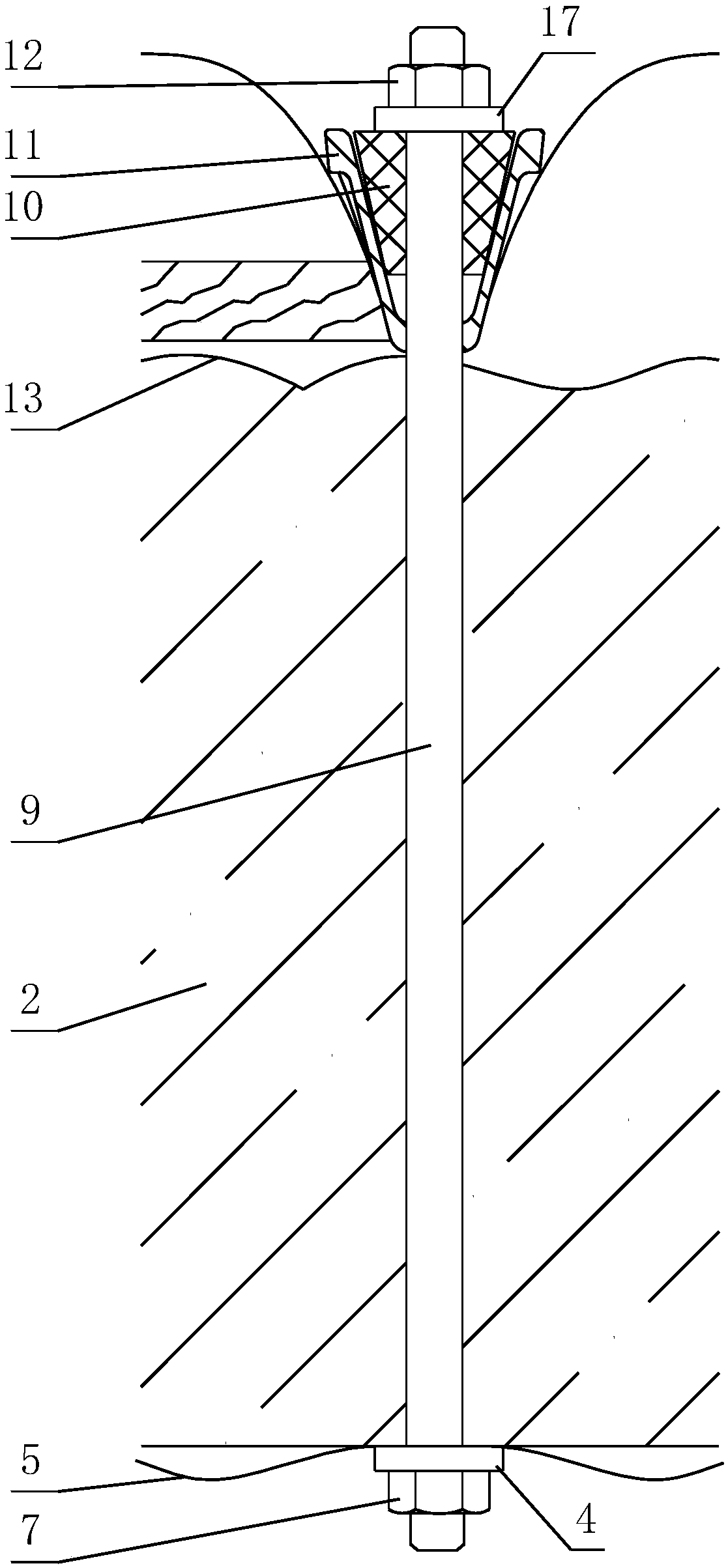

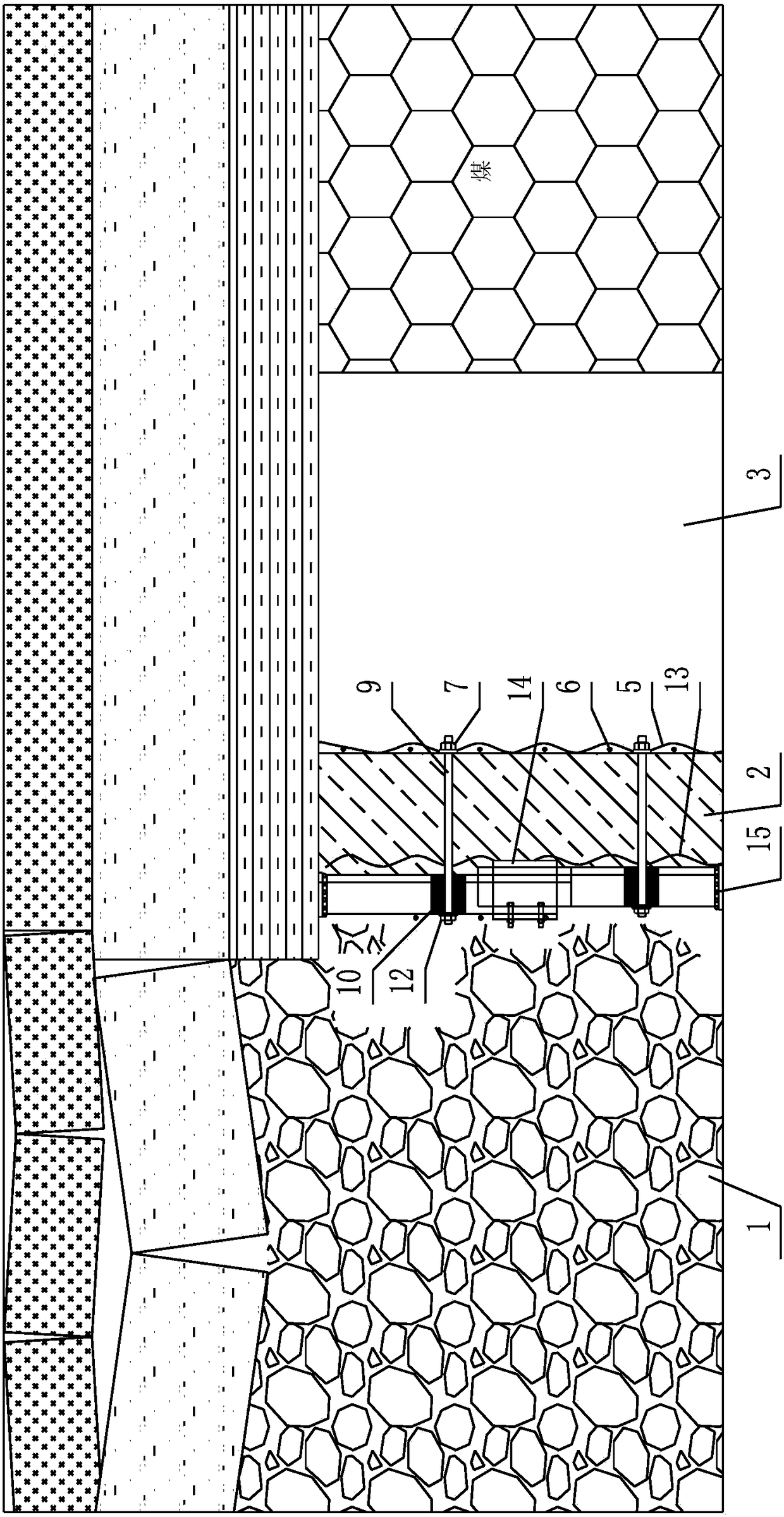

[0012] Such as Figure 1-Figure 3 As shown, the present invention comprises the following steps: 1), before the roof of the goaf collapses, U-shaped steel pillars 11 are erected successively along the top cutting line, and the middle part of U-shaped steel pillars 11 is provided with a telescopic joint 14, and the top contact surface and the bottom have Anti-skid plate 15 is welded with threaded steel on the anti-skid plate 15, which is used to improve the self-stabilizing ability of U-shaped steel pillar 11; 2), laying inner metal mesh 13 on the outside of U-shaped steel pillar 11, and inner metal mesh 13 is fixed with U-shaped steel pillar 11 ; 3), in the outer end roadway of the metal mesh 13 in the distance, a temporary single hydraulic prop 6 is supported, and the inner side of the temporary single hydraulic prop 6 is laid with an outer metal mesh 5, and the temporary single hydraulic prop at the front end of the inner and outer metal mesh Lay temporary wooden formwork 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com