Impact-type composite threaded-connection drilling tool

A threaded connection and impact technology, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of increased impact force, local stress concentration, reduced load-bearing force arm, and external thread fracture, etc., to achieve anti-axial Strong axial load capacity, good bending moment resistance, and good root strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

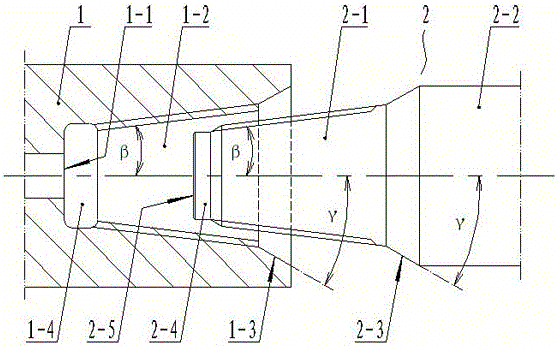

[0028] Such as Figure 1~3 As shown: the trouser body 1 of the drill bit is provided with a tapered threaded blind hole 1-2, and the drill rod 2 is connected with the threaded blind hole through the external threaded section 2-1 located at its front part; the taper bottom of the threaded blind hole The angle β between the generatrix of the hole and the axis of the bottom hole is 1-10°, preferably 5°.

[0029] The front end of the external thread section 2-1 has a cylindrical transition section 2-4 with a diameter smaller than the minimum cross-sectional diameter of the threaded blind hole 1-2, and the length of the transition section is less than or equal to the thread end of the threaded blind hole 1-2 and the bottom of the hole A distance of 1-1; when the external threaded section 2-1 is tightened with the threaded blind hole 1-2, the front end face 2-5 of the transition section 2-4 is in contact with the bottom 1-1 of the threaded blind hole 1-2.

[0030] In order to impro...

Embodiment 2

[0032] On the basis of the foregoing embodiments, the present invention can also adopt the following structures: in order to improve the strength of the drill rod 2, the drill rod 2 adopts a stepped shaft structure with a middle section 2-2; in order to avoid stress concentration, the external thread section 2- 1 and the middle section 2-2 are connected and transitioned through the conical shoulder 2-3; the angle γ between the shoulder 2-3 and the axis of the drill rod 2 is 1-10°, preferably 4°. In order to improve the bending strength at the end of the external thread of the drill rod 2, the orifice of the threaded blind hole 1-2 has an inner tapered surface 1-3 matching the shaft shoulder 2-3. When the external threaded section 2-1 is tightened with the threaded blind hole 1-2, only the front end face 2-5 of the transition section 2-4 is in contact with the bottom 1-1 of the threaded blind hole 1-2, while the shoulder 2- The outer tapered surface of 3 is not in contact with ...

Embodiment 3

[0034] On the basis of the above embodiments, the present invention can also adopt the following structure: in order to facilitate the processing of internal threads, an undercut 1-4 is provided between the threaded blind hole 1-2 and the hole bottom 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com