An automatic direct freezing transparent ice cube ice maker

An ice maker and ice cube technology, which is applied in ice making, refrigerators, compressors, etc., can solve the problems of easy pollution of ice cubes, high labor intensity, and long ice making time, and avoid the defects of easy damage to ice cubes , Reduce labor intensity, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention will now be further explained in conjunction with the description of the drawings and the embodiments:

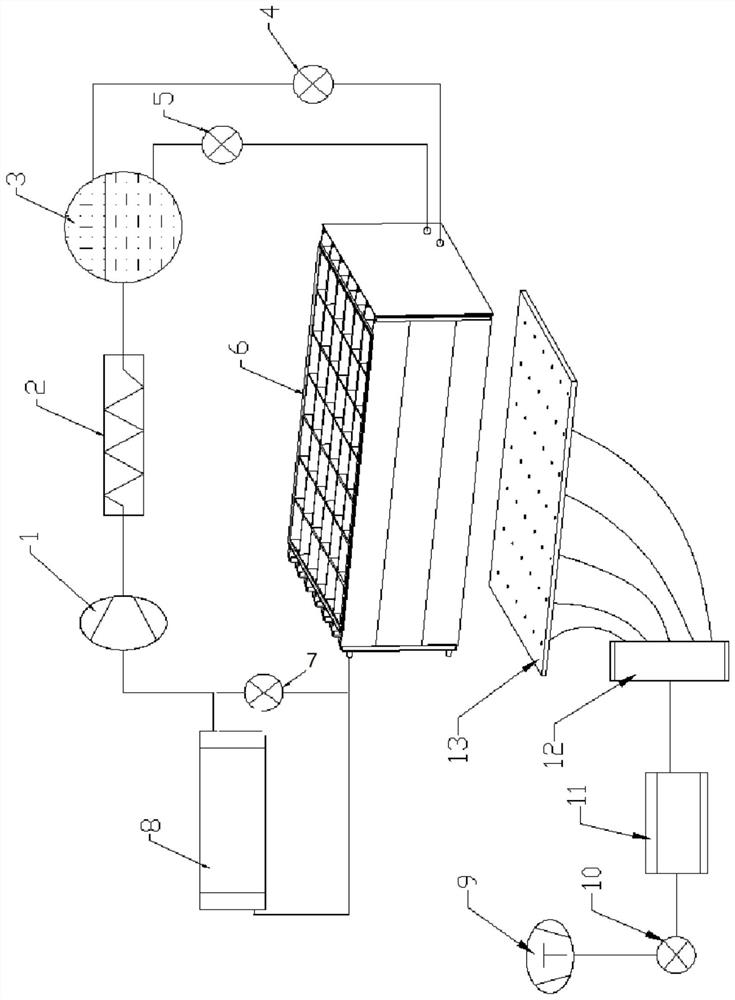

[0020]referencefigure 1, An automatic direct freezing type transparent ice cube ice maker, comprising a direct freezing type ice making assembly, the direct freezing type ice making assembly includes a refrigeration compressor 1, a condenser 2, a gas-liquid storage tank 3, and a liquid supply solenoid valve 4. Ice melting solenoid valve 5, ice cube forming evaporator 6, main return air solenoid valve 7, return air bypass heat exchanger 8;

[0021]The exhaust pipe of the refrigeration compressor is connected to the condenser and the gas-liquid storage tank in sequence, and the outflow of the gas-liquid storage tank is divided into a liquid flow channel and a gas flow channel;

[0022]The liquid flow channel is connected to the ice cube forming evaporator through the liquid supply solenoid valve, and the outlet pipe of the ice cube forming evaporator flows back t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com